The oil and gas industry operates in some of the most hostile environments on Earth, from deep-sea subsea fields to high-pressure, high-temperature (HPHT) reservoirs. Materials used in this sector must withstand relentless exposure to corrosive fluids (brine, H2S, CO2), extreme pressures, fluctuating temperatures, and mechanical stresses. Conventional materials often succumb to rapid degradation, leading to costly failures, environmental hazards, and significant downtime. Titanium, with its unique combination of properties, has become an indispensable material for ensuring the integrity and operational efficiency of critical infrastructure in these challenging conditions.

Operators in the oil and gas sector constantly battle against material failure and the associated risks. Titanium's inherent advantages directly address these critical pain points:

Unparalleled Corrosion Resistance: The primary reason for titanium's widespread adoption in oil and gas is its exceptional resistance to various forms of corrosion. It forms a stable, passive oxide layer that provides outstanding protection against general corrosion, pitting, crevice corrosion, and stress corrosion cracking in chloride-rich environments (e.g., seawater, produced water) and sour service (H2S) and sweet (CO2) conditions [1]. This is crucial for components exposed to aggressive well fluids and marine environments.

High Strength-to-Weight Ratio: In offshore and subsea applications, weight reduction is paramount for reducing structural loads, simplifying installation, and minimizing operational costs. Titanium alloys offer tensile strengths comparable to many steels but at nearly half the density. This allows for lighter designs of risers, umbilicals, and subsea equipment, leading to improved buoyancy, reduced fatigue, and enhanced overall system performance.

Resistance to Erosion and Abrasion: In many oil and gas applications, fluids carry abrasive particles, leading to erosion-corrosion. Titanium's inherent hardness and resistance to cavitation make it an excellent choice for components like pump impellers, valve trims, and flowline sections that experience high-velocity flows and abrasive media.

High-Temperature and High-Pressure (HPHT) Capability: As exploration moves into deeper and more challenging reservoirs, materials must withstand increasingly extreme temperatures and pressures. Certain titanium alloys retain their mechanical properties and corrosion resistance at elevated temperatures (up to 300°C or 570°F and beyond for specialized grades) and high pressures, making them suitable for HPHT downhole tools and production tubing.

Fatigue Resistance: Oil and gas infrastructure, particularly offshore platforms and risers, are subjected to continuous cyclic loading from waves, currents, and operational stresses. Titanium alloys exhibit excellent fatigue strength and crack propagation resistance, contributing to the long-term durability and reliability of critical components, reducing the risk of catastrophic failures.

Reduced Maintenance and Lifecycle Costs: By resisting degradation and extending the operational life of components, titanium significantly reduces the need for frequent inspections, repairs, and replacements. While the initial material cost of titanium can be higher, the substantial savings in maintenance, downtime, and enhanced safety often result in a lower total lifecycle cost for the project.

Titanium's unique properties make it indispensable across a broad spectrum of applications within the upstream, midstream, and downstream sectors of the oil and gas industry.

Offshore Platforms and FPSOs: Titanium is used in critical structural components, piping systems, and heat exchangers due to its corrosion resistance in seawater and reduced weight, which is beneficial for floating structures.

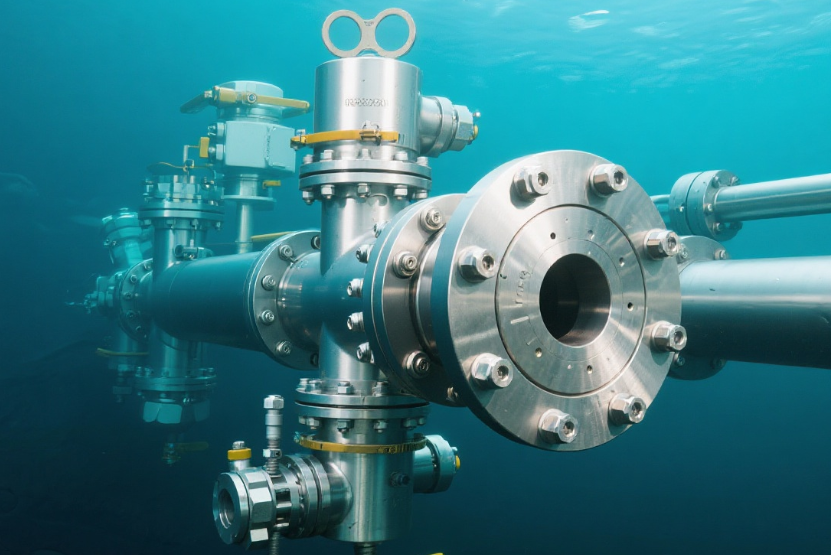

Subsea Production Systems: Titanium is ideal for subsea manifolds, risers (e.g., drilling risers, production risers), flowlines, and umbilical components. Its corrosion resistance to seawater and produced fluids, combined with its high strength-to-weight ratio, enables reliable operation in deepwater and ultra-deepwater environments, where traditional materials would be too heavy or susceptible to corrosion.

Downhole Applications: In drilling and completion, titanium is used for downhole tools, well casings, tubing, and packers. Its ability to withstand high pressures, temperatures, and corrosive well fluids (including H2S and CO2) ensures integrity and extends the life of downhole equipment.

Drill Pipe and Risers: Titanium drill pipe offers significant advantages in extended reach drilling and deepwater operations due to its lighter weight, which reduces hook load and allows for longer horizontal sections. Titanium risers are used for their flexibility, fatigue resistance, and corrosion resistance in dynamic subsea environments.

Pipelines: While less common for long-distance pipelines due to cost, titanium is used in critical sections of pipelines exposed to highly corrosive media or requiring exceptional durability, such as flowlines from wells to processing facilities.

Storage Tanks: For specific corrosive chemicals or refined products, titanium-lined or solid titanium storage tanks provide a safe and durable solution, preventing material degradation and contamination.

Heat Exchangers: Titanium heat exchangers are widely used in refineries and petrochemical plants for processes involving corrosive media, such as sulfuric acid coolers, chloride-containing streams, and sour water strippers. Their superior corrosion resistance ensures efficient heat transfer and long service life.

Reactors and Pressure Vessels: For highly corrosive chemical reactions within refineries, titanium-lined or solid titanium reactors and pressure vessels offer robust solutions, ensuring operational safety and product purity.

Piping Systems, Pumps, and Valves: Similar to chemical processing, titanium is used for critical piping, pumps, and valves in refinery units handling aggressive chemicals, ensuring system integrity and minimizing leaks.

SG Trading Asia Co., Limited supplies a comprehensive range of titanium grades specifically engineered and certified to meet the rigorous demands of the oil and gas industry, adhering to the highest international standards.

Grade 2 (Commercially Pure Titanium): This is the most widely used CP titanium grade in oil and gas due to its excellent balance of strength, ductility, and superior corrosion resistance in oxidizing and mildly reducing environments. It is suitable for general applications involving seawater, brine, and various process fluids.

Grade 5 (Ti-6Al-4V): The workhorse alloy, offering an outstanding combination of high strength, light weight, and excellent corrosion resistance. It is extensively used in structural components, risers, subsea equipment, and downhole tools where high strength and fatigue resistance are critical.

Grade 7 (Ti-0.2Pd): This palladium-enhanced CP titanium offers significantly improved corrosion resistance, particularly against crevice corrosion and reducing acids (e.g., sulfuric acid, hydrochloric acid) at elevated temperatures. It is often chosen for highly corrosive well fluids and specific process streams.

Grade 12 (Ti-0.3Mo-0.8Ni): Provides enhanced crevice corrosion resistance compared to CP grades, especially in hot brine environments, and offers higher strength than CP titanium. It is a cost-effective alternative to Grade 7 in certain moderately reducing environments.

Grade 9 (Ti-3Al-2.5V): A medium-strength alpha-beta alloy with good weldability and formability. It is often used for seamless tubing in heat exchangers and hydraulic lines where a balance of strength and corrosion resistance is required.

Grade 23 (Ti-6Al-4V ELI): The Extra Low Interstitial version of Grade 5, offering enhanced ductility and fracture toughness, making it suitable for fracture-critical components and applications requiring superior fatigue performance.

ASTM: Various ASTM standards cover titanium mill products (e.g., ASTM B338 for seamless and welded tube, ASTM B265 for plate, sheet, and strip, ASTM B348 for bar, ASTM B363 for fittings).

ASME: Applicable for pressure vessel and piping components, ensuring design and fabrication integrity.

NACE: Standards related to corrosion control, particularly in sour service (H2S environments) and other aggressive conditions prevalent in oil and gas. Compliance with NACE MR0175/ISO 15156 is often required for materials in sour service.

NORSOK M-650: A Norwegian standard for material selection and qualification for offshore oil and gas installations, widely recognized globally for high-integrity applications. Standard Titanium is NORSOK M-650 approved.

API: Relevant API specifications for tubular goods and other equipment used in drilling and production.

Manufacturing titanium components for the oil and gas industry demands exceptional precision, robust quality control, and adherence to the most stringent regulatory and industry standards. SG Trading Asia Co., Limited employs state-of-the-art manufacturing processes and rigorous quality assurance protocols to ensure the integrity and reliability of every product, even in the most extreme operating conditions.

Our manufacturing processes are specifically adapted to the unique properties of titanium and the demanding requirements of the oil and gas sector:

Precision Forging and Machining: We utilize advanced forging techniques to produce near-net-shape components, minimizing material waste and subsequent machining. Our state-of-the-art machining centers are equipped to handle the unique challenges of titanium, ensuring tight tolerances and superior surface finishes, crucial for preventing stress concentrations and ensuring long-term performance.

Specialized Welding and Fabrication: Titanium welding requires highly controlled environments (e.g., inert gas purging) to prevent contamination and maintain corrosion resistance. Our certified welders and advanced welding techniques (e.g., TIG, plasma arc welding, electron beam welding) ensure weld integrity and mechanical properties comparable to the base material, critical for pressure-containing components.

Hot and Cold Forming: We employ specialized hot and cold forming techniques to shape titanium into complex geometries for various components, including bends, reducers, and custom pipe sections, while preserving its metallurgical integrity.

Every titanium component undergoes a series of stringent quality checks to guarantee its compliance with specifications and performance requirements:

Chemical Analysis: Verification of precise elemental composition to ensure correct grade and alloy properties, crucial for corrosion resistance and mechanical performance.

Mechanical Testing: Comprehensive testing for tensile strength, yield strength, elongation, hardness, impact toughness, and fatigue properties to confirm mechanical integrity under operational loads.

Corrosion Testing: Specialized corrosion tests (e.g., ASTM G28 for crevice corrosion, ASTM G36 for stress corrosion cracking, NACE TM0177 for sour service) are performed to validate resistance in specific aggressive oil and gas media.

Non-Destructive Testing (NDT): Includes ultrasonic testing (UT), radiographic testing (RT), magnetic particle testing (MT), liquid penetrant testing (PT), and eddy current testing (ET) to detect internal and surface flaws, ensuring the structural integrity of components.

Hydrostatic and Pneumatic Testing: Pressure testing of fabricated components to verify leak tightness and structural integrity under simulated operating conditions, essential for pressure vessels and piping.

Positive Material Identification (PMI): Ensures that the correct material grade is used throughout the manufacturing process, preventing material mix-ups and ensuring compliance with critical specifications.

Full Traceability: A robust quality management system ensures complete traceability from raw material to finished product, providing detailed documentation for every stage of the manufacturing process, which is crucial for regulatory compliance and operational safety.

SG Trading Asia Co., Limited is not merely a material supplier; we are a strategic partner for the oil and gas industry, offering comprehensive solutions and expert support to address complex engineering challenges and optimize project outcomes.

Our in-house capabilities and engineering expertise allow us to provide bespoke titanium solutions:

Custom Designs and Fabrication: We work closely with clients to design and fabricate custom titanium components, including specialized heat exchangers, complex piping spools, and unique subsea equipment, optimized for specific project requirements and challenging operating conditions.

Material Selection Guidance: Our metallurgists and engineers provide expert consultation on selecting the most appropriate titanium grade and form for specific oil and gas environments, considering factors like fluid composition, temperature, pressure, flow rates, and expected service life.

Failure Analysis Support: In cases of material failure with other metals, we can provide insights and recommend titanium solutions to prevent recurrence, leveraging our deep understanding of corrosion mechanisms and material behavior in aggressive environments.

In the global and often volatile oil and gas market, a reliable and efficient supply chain is paramount. SG Trading Asia Co., Limited. is committed to being a dependable partner, ensuring a robust supply chain for high-quality titanium products.

Strategic Sourcing: We maintain strong relationships with reputable titanium producers globally, ensuring a consistent supply of high-quality raw materials and mitigating geopolitical and market risks.

Inventory Management: We strategically manage our inventory of common oil and gas titanium grades and forms (e.g., pipe, plate, bar, fittings) to minimize lead times and support just-in-time manufacturing for our clients, reducing project delays.

Global Logistics: Our experienced logistics team ensures efficient and secure delivery of titanium products to oil and gas project sites worldwide, handling all necessary documentation, customs procedures, and compliance requirements to facilitate smooth transit.

In the demanding and high-stakes world of oil and gas, selecting the right material supplier is a strategic decision that directly impacts project success, operational safety, and long-term profitability. SG Trading Asia Co., Limited. is committed to being that partner, offering not just superior products, but comprehensive solutions and expert support.

Our deep understanding of oil and gas requirements, combined with our commitment to quality, innovation, and customer service, positions us as a preferred choice for titanium materials. Contact us today to discuss your specific oil and gas titanium needs, request a quotation, or explore how our expertise can support your next critical energy project.

Contact Us