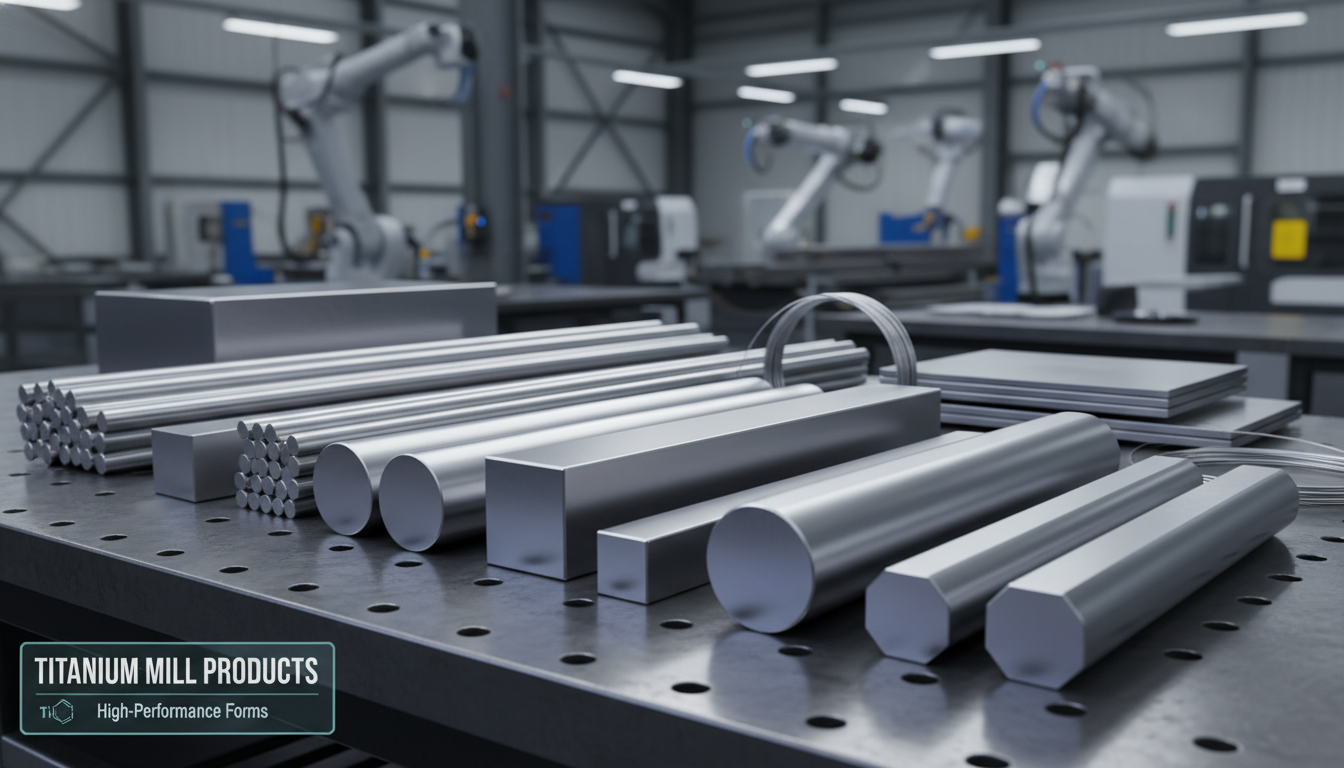

World-class manufacturer and supplier of high-quality titanium Plate, Sheet, Bar, Tube, and Wire. Engineered for exceptional strength, corrosion resistance, and stability.

Request a Custom Quote TodayTitanium mill products are indispensable in industries where performance under extreme conditions is non-negotiable. Our materials offer distinct advantages:

Virtually immune to corrosion in seawater, chloride environments, and aggressive chemical media due to its passive oxide layer.

Offering the strength of steel at nearly half the weight, ideal for weight-critical applications like aerospace.

Non-toxic and non-allergenic CP grades are perfect for medical implants and surgical devices.

Maintains mechanical properties and creep resistance at elevated temperatures, crucial for jet engines.

We supply a diverse portfolio tailored for specific mechanical, chemical, and thermal requirements.

Softest and most ductile, ideal for deep drawing. Used in chemical processing and desalinization.

Most common CP grade, offering a balance of strength, ductility, and weldability. Used in heat exchangers.

The "workhorse" alloy. High strength and excellent fatigue resistance. Extensively used in aerospace.

CP titanium with Palladium added for enhanced corrosion resistance in reducing acid environments.

Medium-strength alloy with excellent cold-working properties, ideal for hydraulic tubing.

Extra-Low Interstitial version of Grade 5, offering superior fracture toughness for medical implants.

Adhering to international specifications such as ASTM, ASME, AMS, and MIL.

Used for structural components, heat exchanger plates, and pressure vessels. Available in various thicknesses.

Round, square, hexagonal, and rectangular shapes. Critical for machining parts, fasteners, and implants.

Seamless and welded options for fluid conveyance in corrosive environments like chemical plants.

Used in welding filler material, springs, and medical applications like orthodontic wires.

| Parameter | Specification Details | Customization Options |

|---|---|---|

| Material Grades | CP Grades 1, 2, 3, 4; Alloys Grades 5, 7, 9, 12, 23 | Specific chemical control, non-standard grades (e.g., Gr 16, 17, 18). |

| Product Forms | Plate, Sheet, Strip, Bar, Rod, Billet, Tube & Pipe, Wire, Coil | Custom forging, precision machining, specialized surface finishes. |

| Standards | ASTM B265, B348, B338 | Compliance with AMS, ASME, MIL specifications. |

| Dimensions | Standard metric and imperial sizes | Non-standard length, width, diameter, and wall thickness tolerances. |

Advanced techniques including Vacuum Arc Remelting (VAR), forging, and rolling with full material traceability.

Expert consultation to select the perfect titanium grade and form factor for your specific environment.

Timely and secure delivery worldwide with full material certification, regardless of volume.

CP Titanium (Grades 1-4) is 99% pure, selected for corrosion resistance. Alloys (e.g., Grade 5) add elements like Aluminum to increase strength and heat resistance.

Grade 5 (Ti-6Al-4V) is the workhorse of aerospace due to its exceptional strength-to-weight ratio and high-temperature performance.

Yes, but it requires specialized techniques like GTAW with inert gas shielding to prevent atmospheric contamination.

Ready to start your next project with high-quality titanium mill products? Contact our technical team for a competitive quote.

Contact Our Experts