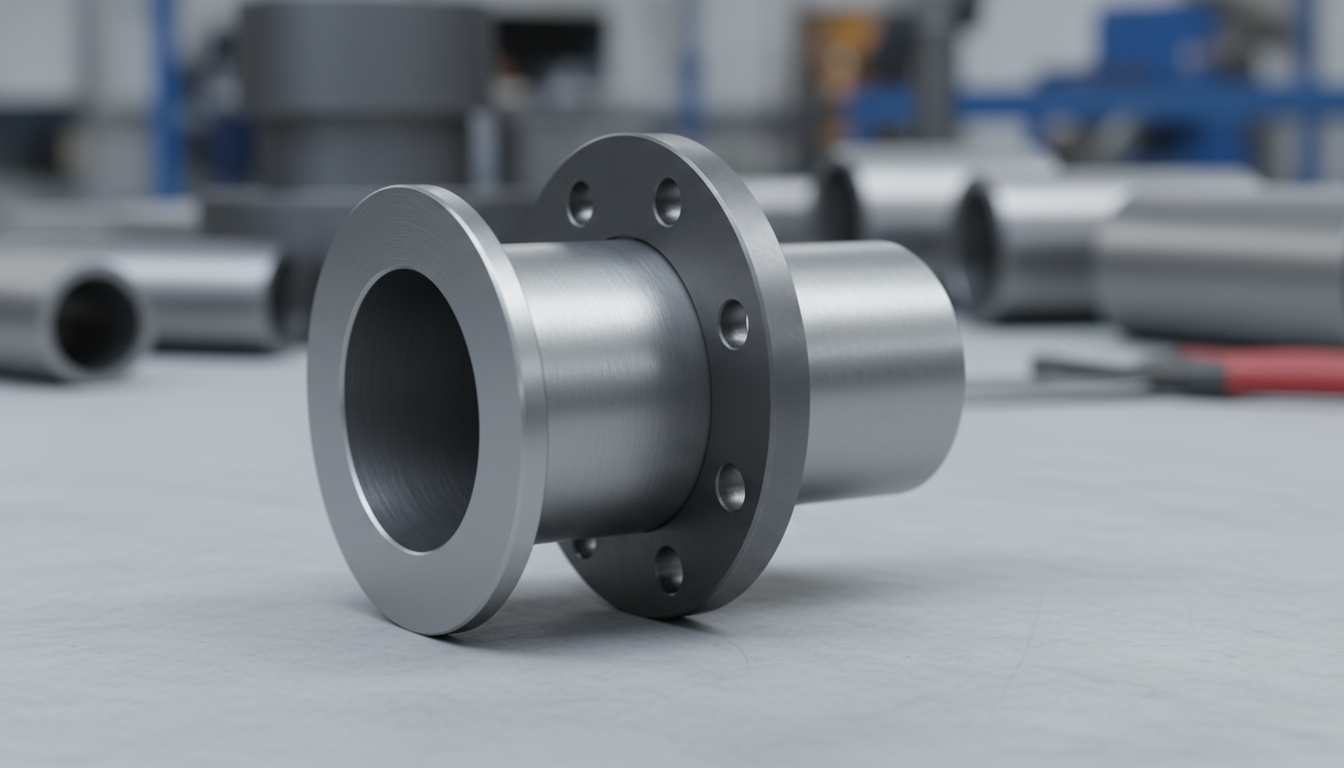

Titanium stub ends, used with lap joint flanges, enable easy dismantling and cost-effective corrosion resistance in demanding piping systems. Standard Titanium Co. offers high-quality stub ends for reliable performance.

Request a QuoteTitanium stub ends, used with lap joint flanges, enable easy dismantling and cost-effective corrosion resistance in demanding piping systems. Standard Titanium Co. offers high-quality stub ends for reliable performance.

Rotatable lap joint flanges simplify bolt alignment, reducing installation time.

Combines titanium stub ends with economical flanges for chemical processing.

Resists chlorides, acids, and seawater in marine and oil & gas.

High strength and erosion resistance ensure longevity.

Supports flexible configurations and modifications.

ASME B16.9: Factory-made wrought buttwelding fittings.

ASTM B363: Seamless and welded titanium alloy fittings.

Grades: Commercially Pure (Grade 1, 2, 3, 4), Grade 5 (Ti-6Al-4V), Grade 7 (Ti-0.2Pd).

| Type | Description | Applications |

|---|---|---|

| Type A Stub Ends | Square face for standard lap joint flanges | General piping connections |

| Type B Stub Ends | Radiused face for matching flanges | Enhanced stress distribution |

Nominal Pipe Sizes (NPS): 0.5 inch (DN15) to 48 inches (DN1200).

Wall Thickness Schedules: Sch 10S, Sch 40S, Sch 80S, Sch 160, XXS.

Seamless and Welded Construction: Seamless for high-pressure, welded for cost-efficiency.

Precision Forming: Deep drawing and hydroforming for accuracy.

Heat Treatment: Annealing for optimal properties.

Dimensional Inspection: Ensures ASME B16.9 compliance.

Non-Destructive Testing (NDT): Ultrasonic, radiographic, and liquid penetrant testing.

Chemical and Mechanical Testing: Verifies composition and strength.

Hydrostatic Testing: Confirms leak tightness under pressure.

Pipelines and heat exchangers handling aggressive chemicals.

Offshore platforms, risers, and wellhead equipment.

Seawater cooling and ballast systems for vessels.

Condenser and cooling water lines in power plants.

Sterile water and gas process lines for purity-critical applications.

Various applications requiring corrosion resistance.

Easy installation and maintenance lower labor expenses.

Combines titanium with economical flanges.

Prevents leaks for personnel and environmental protection.

Reliable connections minimize downtime.

Meets stringent standards.

Non-Standard Dimensions: Custom diameters and face types.

Specialized Machining: Tight tolerances and finishes.

Integrated Assemblies: Pre-fabricated spools for efficiency.

Surface Treatments: Anodizing or passivation for specific needs.

Strategic Stockholding: Ample inventory for rapid dispatch.

Transparent Pricing: Tailored quotes for specific needs.

Global Logistics: Shipping with EXW, DDP, FOB, CIF, and FAS terms.

Contact our team for product details or a free quote. We provide tailored fabrication for unique piping needs.

Request a Quote Now