As a premier supplier of medical-grade titanium, we provide materials with exceptional biocompatibility, superior strength, and the proven ability to osseointegrate, ensuring the long-term success of critical implants and devices.

Contact Our Experts

Titanium has earned its reputation as the gold standard in medical applications due to its unique combination of properties that directly address the most critical requirements of the human body. Our medical-grade titanium products are engineered to meet the highest biocompatibility and performance standards.

Highly inert and non-toxic, titanium minimizes the risk of adverse immune response, inflammation, or allergic reactions, making it safe for long-term implantation in the human body.

Titanium has the unique ability to fuse directly with living bone tissue, forming a strong, stable, and permanent bond essential for the longevity of dental and orthopedic implants.

The passive oxide layer on titanium prevents the release of metallic ions into the body, maintaining the implant's structural integrity against the corrosive environment of bodily fluids.

Titanium is non-ferromagnetic, ensuring patients can safely undergo Magnetic Resonance Imaging (MRI) and Computed Tomography (CT) scans without image artifacts or risk.

We supply titanium alloys specifically processed and certified to meet the stringent requirements of the medical industry, adhering to the highest international standards including ASTM, ISO, and FDA guidelines.

| Alloy Grade | Key Characteristics | Typical Applications |

|---|---|---|

| Ti-6Al-4V ELI (Grade 23) | Extra Low Interstitial, superior fracture toughness, excellent fatigue strength, certified to ASTM F136 and ISO 5832-3 | Hip and knee replacements, spinal implants, orthopedic devices |

| CP Titanium Grade 4 | Commercially pure, highest strength among CP grades, excellent biocompatibility, certified to ASTM F67 and ISO 5832-2 | Dental implant fixtures, abutments, surgical instruments |

| CP Titanium Grades 1-3 | Lower strength, excellent corrosion resistance, ideal for lower-stress applications, certified to ASTM F67 | Pacemaker casings, medical device housings, fasteners |

| Ti-6Al-7Nb | Modern alternative to Grade 23, excellent biocompatibility, high strength, certified to ISO 5832-3 | Advanced orthopedic implants, high-performance dental devices |

We can provide customized titanium materials with complete certification documentation (MTRs, CoCs) according to your specific medical device requirements.

Request Medical-Grade SamplesOur medical-grade titanium products are trusted by leading medical device manufacturers and healthcare providers worldwide for their critical applications in orthopedics, dentistry, and surgical devices.

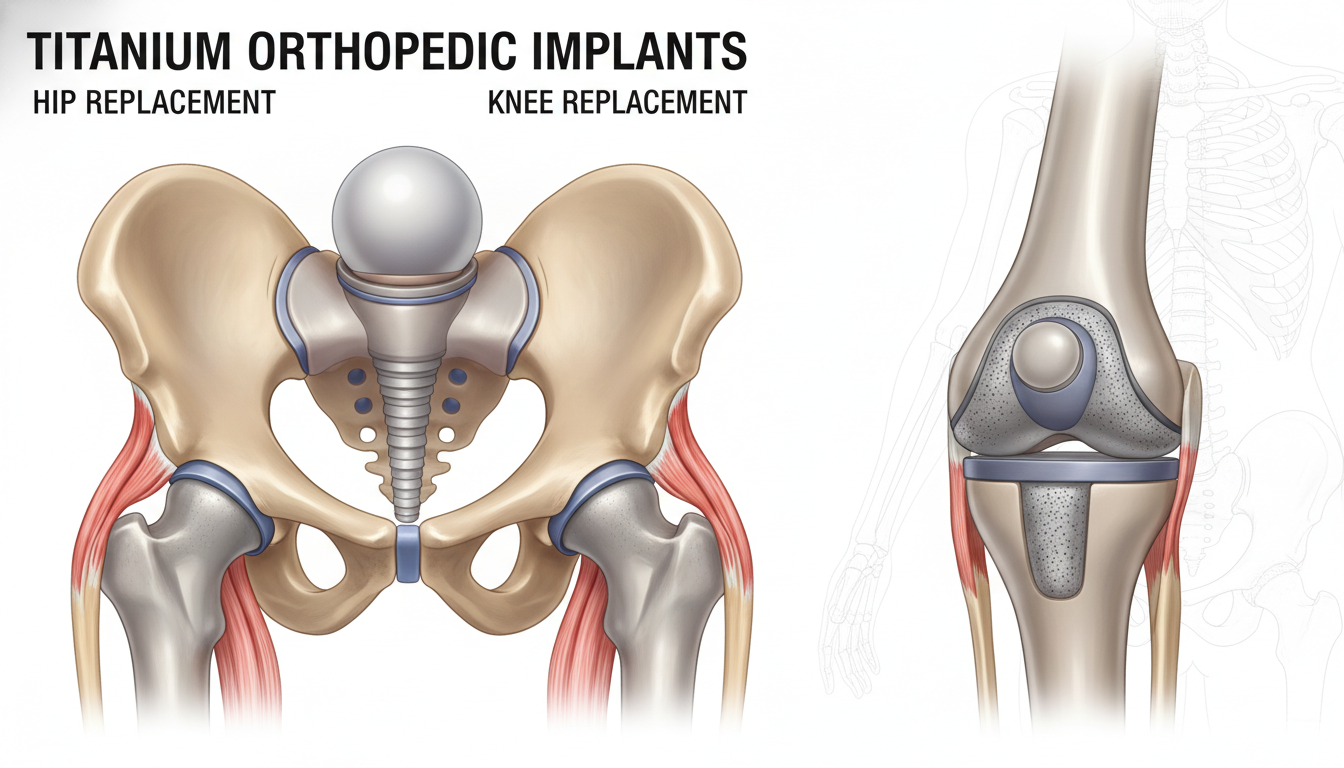

Titanium is the material of choice for orthopedic implants due to its exceptional strength-to-weight ratio, biocompatibility, and proven long-term performance in the human body.

✓ Joint Replacements: Femoral stems and tibial trays for hip, knee, shoulder, and elbow replacements, providing superior osseointegration and long-term stability.

✓ Trauma Fixation: Bone plates, screws, rods, and intramedullary nails for fracture stabilization and healing.

✓ Spinal Implants: Interbody fusion cages, pedicle screws, and rods for spinal fusion and stabilization procedures.

Titanium's osseointegration capability makes it the ideal material for dental implants, providing a permanent and stable foundation for prosthetic teeth.

✓ Dental Implant Fixtures: The root-like component surgically placed into the jawbone, providing a stable foundation for crowns, bridges, and dentures.

✓ Abutments: Connectors placed on top of implant fixtures to support prosthetic teeth, ensuring biocompatible and durable connections.

✓ Custom Dental Components: Specialized components for complex dental restorations and orthodontic applications.

Beyond implants, titanium is essential for a wide range of medical devices and surgical instruments where biocompatibility, precision, and durability are critical.

✓ Pacemaker Casings: Biocompatible protective enclosures for pacemakers and other implantable electronic devices.

✓ Surgical Instruments: Lightweight, corrosion-resistant forceps, retractors, scissors, and other precision surgical tools.

✓ Fasteners and Hardware: Medical-grade bolts, screws, and fasteners for device assembly and fixation.

We understand that medical-grade materials demand the highest standards of quality, traceability, and compliance. Our manufacturing processes are designed to meet the most stringent requirements of the medical device industry.

✓ ISO 13485:2016: Medical Devices Quality Management System

✓ ISO 9001:2015: Quality Management System

✓ ASTM F67 & F136: Standard Specifications for Unalloyed Titanium and Titanium Alloys for Surgical Implants

✓ ISO 5832-2 & 5832-3: Implants for Surgery - Metallic Materials

Every batch of medical-grade titanium is fully traceable from raw material procurement through final product delivery. We provide comprehensive documentation including:

✓ Material Test Reports (MTRs) with complete chemical composition and mechanical properties

✓ Certificates of Conformance (CoCs) confirming compliance with ASTM and ISO standards

✓ Batch tracking and lot identification for full supply chain transparency

Our specialized processing techniques ensure that medical-grade titanium meets the highest standards for purity, mechanical properties, and surface finish:

✓ Vacuum Arc Remelting (VAR) for superior material purity and consistency

✓ Precision forging and rolling to achieve exact mechanical properties

✓ Rigorous testing including tensile, hardness, and corrosion resistance verification

Partner with us for reliable, certified medical-grade titanium that meets the highest industry standards. Our team is ready to support your medical device development with technical expertise and customized solutions.

Contact Our Medical ExpertsOur team of medical material specialists is ready to provide expert guidance and support for your project.