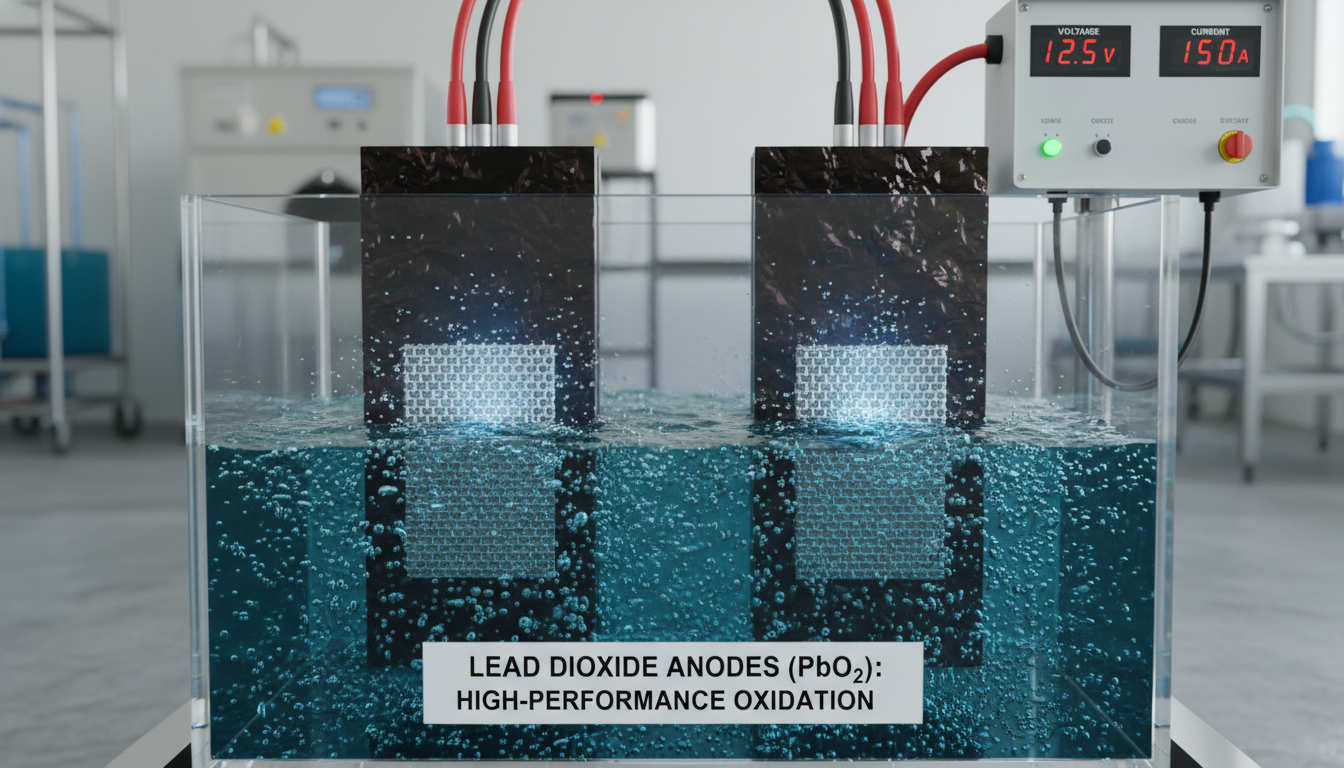

Our Lead Dioxide Anodes (PbO₂) are engineered for exceptional performance in oxidation processes. With their high conductivity and stability, they are vital components in a wide range of applications, including electroplating, water treatment, and electrochemical synthesis, effectively driving reactions and enabling efficient energy conversion.

Request a Quote

Lead Dioxide Anodes are typically based on a titanium substrate, where a dense layer of lead dioxide is formed through electrodeposition or thermal decomposition. Their unique electrochemical properties make them excel in areas where traditional electrodes are inadequate.

Compared to Iridium or Ruthenium-based anodes, PbO₂ has a higher oxygen evolution overpotential, giving it higher selectivity and current efficiency in reactions requiring high anodic potential, such as electrochemical oxidation and ozone generation.

Exhibits outstanding chemical stability in highly acidic (e.g., sulfuric acid) and strong oxidizing media, making it particularly suitable for complex and corrosive electrolyte environments.

The lead dioxide coating offers good conductivity and can withstand extremely high operating current densities, meeting the demands of industrial production for high efficiency and high throughput.

Compared to noble metal anodes (like Platinum, Iridium), the raw material cost of lead dioxide is lower, giving it a significant economic advantage in large-scale industrial applications.

Substrate Material: Commercially Pure Titanium (Gr1, Gr2), or valve metals like Niobium and Tantalum can also be used.

Coating Material: High-purity β-PbO₂, with coating thickness customizable based on application needs.

Common Shapes: Mesh, Plate, Rod, Tube, Custom Irregular Structures.

Coating Process: Electrodeposition (e.g., in a lead sulfate system), ensuring a uniform and firmly bonded coating.

| Parameter | Typical Value/Feature | Application Advantage |

|---|---|---|

| Oxygen Evolution Overpotential | High (approx. 1.7-1.9 V vs. SHE) | Favorable for Electrochemical Oxidation, Ozone Generation |

| Current Density | Up to 10000 A/m² | Suitable for High-Intensity Electrolysis Operations |

| Corrosion Resistance | Stable in Strong Acidic Media | Long Lifespan, Low Maintenance |

| Substrate Lifespan | Dimensionally Stable, Recoatable | Reduces Long-Term Operating Costs |

Efficiently degrades refractory organic pollutants (such as dyes, phenols), used in electrochemical oxidation and electro-Fenton processes for deep wastewater purification.

Used for the electrowinning and refining of non-ferrous metals like zinc, copper, and nickel, especially in sulfuric acid systems, replacing traditional lead-silver alloy anodes to improve product purity.

Serves as an anode material with high selectivity and stability in the industrial electrolytic production of perchlorates and chlorates.

Used for the electrochemical preparation of ozone; its high oxygen evolution overpotential is conducive to ozone generation, widely applied in water disinfection and air purification.

Used for the electrochemical synthesis of organic and inorganic compounds, such as the preparation of persulfates and hydrogen peroxide.

Contact our expert team for customized solutions and technical support. We are committed to helping your electrochemical projects succeed with the most competitive prices and exceptional quality.

Inquire for a Quote Now