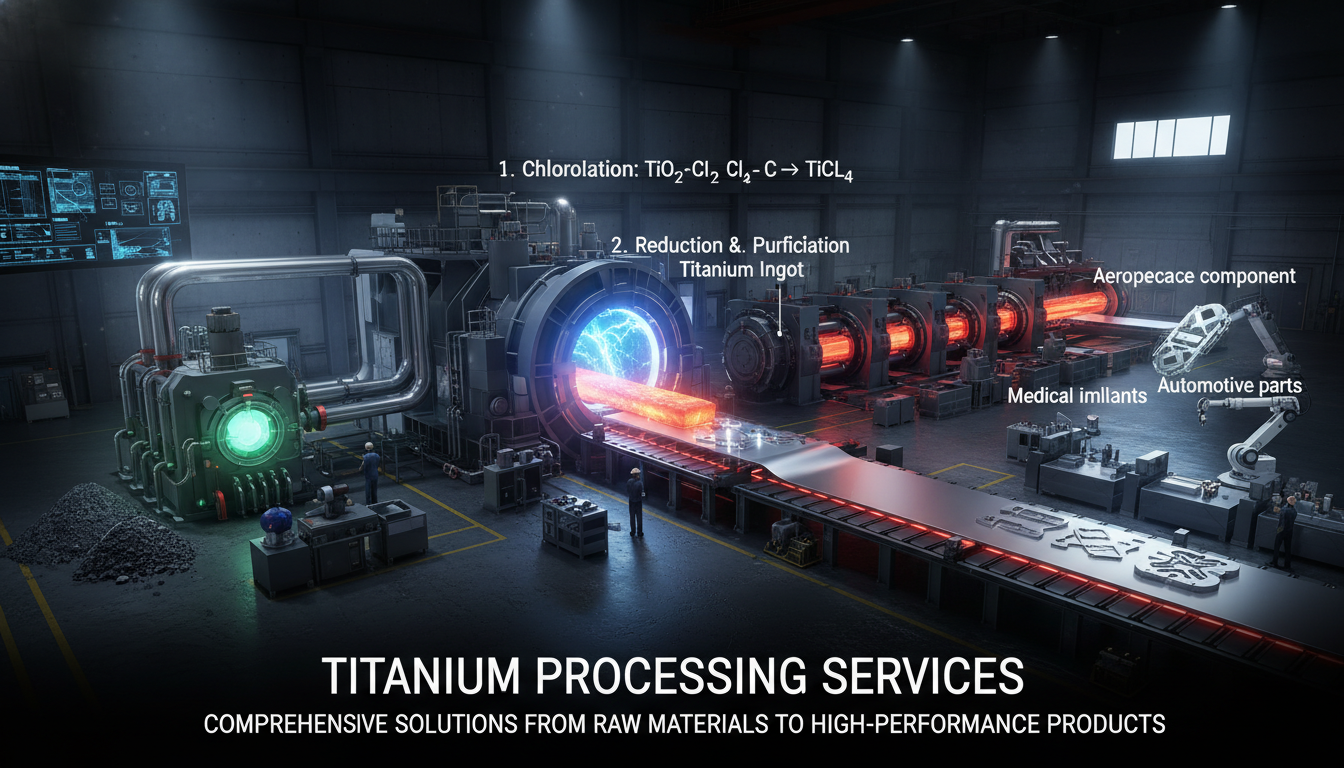

Comprehensive Solutions from Raw Materials to High-Performance Products

We are committed to providing comprehensive, one-stop titanium processing services covering every stage from raw material handling to final product formation. With advanced technology, precision equipment, and an experienced professional team, we deliver customized solutions to global clients, ensuring every titanium product meets the highest industry standards.

High-Precision Manufacturing

Precision machining is a critical stage in titanium product manufacturing, aimed at transforming titanium alloy raw materials into components with complex geometries and strict tolerances. We employ state-of-the-art Computer Numerical Control (CNC) technology to ensure high precision and efficiency throughout the machining process.

CNC Machining: We offer comprehensive CNC turning, milling, drilling, and grinding services. Our equipment achieves micron-level precision to meet the stringent requirements of aerospace and medical devices.

Electrical Discharge Machining (EDM): For complex internal structures or high-hardness materials, we utilize EDM technology to produce extremely fine and stress-free components.

Application Areas: Aerospace engine components, medical implants, precision instrument assemblies, high-performance automotive parts.

Forming and Joining Technologies

Titanium fabrication involves transforming titanium materials into required structures and components through various forming and joining techniques. We strictly control the fabrication process to maintain titanium's excellent properties.

Welding: Proficient in TIG, plasma arc, and laser welding with strict inert gas shielding to ensure weld purity and strength.

Bending and Forming: Professional bending, stamping, stretching, and rolling services with precise temperature control to avoid cracking.

Cutting: Advanced laser, waterjet, and plasma cutting for high precision and low heat-affected zones.

Application Areas: Chemical reactors, heat exchangers, piping systems, offshore platform structural components.

Ensuring Material Purity

Melting and alloying are crucial links in the titanium production chain, directly determining the purity and performance of the final product.

Vacuum Arc Remelting (VAR): The primary method for producing high-quality titanium ingots, effectively removing impurities in a vacuum environment.

Electron Beam Cold Hearth Remelting (EBCHR): Advanced technology for removing high-density inclusions and processing titanium scrap with higher cleanliness.

Custom Alloys: Developing customized titanium alloys based on specific performance requirements like higher strength or biocompatibility.

Application Areas: High-performance aerospace alloys, medical-grade titanium alloys, specialty industrial alloys.

Optimizing Mechanical Properties

Heat treatment is used to manipulate the microstructure and enhance mechanical properties such as ductility, fracture toughness, and thermal stability.

Annealing: Eliminating internal stresses and improving material ductility and plasticity.

Stress Relieving: Reducing residual stresses after mechanical processing or welding to prevent distortion.

Solution Treating and Aging: Significantly improving alloy strength and hardness for age-hardenable titanium alloys.

Application Areas: Aerospace structural components, medical devices, high-stress parts.

Enhancing Surface Performance

Surface treatment improves properties such as corrosion resistance, wear resistance, biocompatibility, or aesthetics.

Anodizing: Forming a dense oxide film to improve corrosion resistance and impart rich colors.

Polishing and Grinding: Achieving high-gloss, defect-free surfaces for medical implants and optical components.

Sandblasting: Removing oxide layers and creating a uniform rough surface for subsequent coating.

Application Areas: Medical implants, biomedical devices, decorative components, chemical equipment linings.

Professional Expertise & Experience: Years of industry experience with a team of senior engineers.

Advanced Equipment & Innovation: World-class CNC centers, welding equipment, and melting furnaces.

Strict Quality Control: Adherence to ISO 9001:2015 and ISO 13485 standards with full traceability.

Customized Solutions: Personalized services from design to material selection.

Fast Delivery & Global Service: Optimized production and global logistics network.

Aerospace: Aircraft structural components, engine turbine blades, landing gear parts.

Medical Devices: Orthopedic implants, surgical instruments, dental implants.

Chemical & Marine Engineering: Reactors, heat exchangers, seawater desalination equipment.

Automotive Industry: High-performance exhaust systems, connecting rods, valves.

Energy Sector: Nuclear power plant components, oil and gas extraction equipment.

Whatever your titanium processing needs may be, we look forward to working with you.

Get a Customized Solution