What is Titanium and Why is it So Versatile?

Titanium is a remarkable metallic element (chemical symbol Ti, atomic number 22 on the periodic table) that has revolutionized modern engineering and manufacturing. When people ask "what is titanium used for", the answer spans an extraordinary range of applications—from life-saving medical implants to supersonic aircraft, from everyday consumer products to cutting-edge 3D printing technologies.

Discovered in 1791 by William Gregor in Cornwall, Great Britain, titanium metal derives its name from the Titans of Greek mythology, reflecting its exceptional strength. Despite being the ninth most abundant element in Earth's crust, titanium remained largely a laboratory curiosity until the mid-20th century when efficient extraction methods made commercial production viable. Today, understanding the usage of titanium and titanium uses is essential for engineers, designers, and manufacturers across virtually every industry.

Before exploring the diverse uses for titanium, it's crucial to understand what makes this element Ti so special. The titanium metal possesses a unique combination of properties that justify its higher cost compared to conventional metals:

Exceptional Strength-to-Weight Ratio: Titanium boasts the highest strength-to-weight ratio of any structural metal. Titanium plate of the same weight as copper would be double the size, and 75% larger than stainless steel. This means engineers can use far less titanium to achieve the same structural strength, making it ideal for weight-critical applications.

Outstanding Corrosion Resistance: Titanium spontaneously forms a protective oxide film when exposed to oxygen, providing remarkable resistance to corrosion from seawater, chlorine, and many acids. This passive layer makes titanium virtually impervious to rust and degradation in harsh environments.

Biocompatibility: The human body tolerates titanium exceptionally well, with minimal immune response or rejection. Its density closely matches human bone, allowing natural integration. We naturally ingest approximately 0.8mg of titanium daily without adverse effects.

High Temperature Performance: With a melting point of 1,668°C (3,034°F), titanium alloys maintain their mechanical properties at elevated temperatures where other metals would fail or melt.

Non-Magnetic and Non-Toxic: These properties make titanium suitable for sensitive electronic applications and safe for prolonged contact with human tissue.

The titanium in aerospace industry represents one of the most significant uses of titanium, consuming approximately 60-70% of all titanium metal produced globally. The aerospace sector's demand for titanium continues to grow, with projections suggesting 1.2 million tons needed over the next 20 years for commercial aviation alone.

The SR-71 "Blackbird" reconnaissance aircraft was the first to extensively use titanium alloys in its structure and skin. Flying at speeds exceeding 3,500 km/h (three times the speed of sound), the Blackbird's aerodynamic friction generated such intense heat that any other metal would literally melt. The aircraft's standard evasive maneuver when fired upon was simply to accelerate and outrun the missile—a testament to both its speed and the heat-resistant properties of titanium.

Today's commercial aircraft incorporate substantial amounts of titanium:

The Airbus A380 uses approximately 70 tons of titanium for structural components and fittings

The Boeing 787 Dreamliner utilizes titanium extensively in its composite-metal joints

Modern jet engines contain titanium alloy compressor blades, discs, and casings

Landing gear, hydraulic systems, and firewalls benefit from titanium's strength and heat resistance

Titanium is critical for spacecraft modules, protective shielding, and military aircraft where performance cannot be compromised. The titanium 6AL-4V alloy accounts for nearly 50% of all alloys used in aircraft applications.

The uses of titanium in medicine leverage its exceptional biocompatibility, making it one of the most important materials in modern healthcare. The medical titanium market grows at 5-7% annually, reflecting increasing demand for implants and surgical devices.

Titanium is the material of choice for:

Hip and knee replacements that can last over 20 years

Bone plates, screws, and pins for fracture repair

Spinal fusion devices and vertebral implants

Joint replacement components (hip balls, sockets)

Titanium dental implants integrate directly with jawbone through a process called osseointegration, providing stable, long-lasting tooth replacements. The material's corrosion resistance ensures durability in the mouth's challenging environment.

The high strength-to-weight ratio of titanium makes surgical instruments easier to handle during lengthy procedures while maintaining necessary rigidity and precision.

Heart stents and pacemaker cases

Prosthetic limb components

Surgical needles and sutures

Medical wheelchairs (especially pediatric models that can be adjusted as children grow)

Titanium Alloy 6Al-4V ELI Grade 23 is specifically designed for medical applications, offering enhanced ductility and fracture toughness. Titanium Round Bar is a common form factor for manufacturing these critical medical components.

Titanium's exceptional corrosion resistance makes it invaluable in chemical processing environments where other metals would rapidly degrade. The usage of titanium in industrial settings significantly extends equipment lifespan and reduces maintenance costs.

Heat exchangers and condensers in chemical plants

Reaction vessels and processing tanks

Piping systems for corrosive chemicals

Chlor-alkali production equipment

Pulp and paper industry components

Desulfurization systems for pollution control

Titanium excels in handling:

Chlorine and chloride solutions

Sulfuric acid and other strong acids

Sodium hypochlorite (bleach)

Organic chemicals and solvents

The material has expanded from initial use in soda ash and caustic soda industries to chlorate, ammonium chloride, urea, organic synthesis, dyes, inorganic salts, pesticides, synthetic fibers, fertilizers, and fine chemical production.

The ocean presents one of the most corrosive environments on Earth, making titanium an ideal material for marine applications. Its resistance to seawater corrosion and ability to withstand both extreme pressures and temperatures make it indispensable for ocean engineering.

Nuclear submarines and deep submersibles

Naval ship components (propellers, shafts, rigging)

Offshore oil and gas platforms

Desalination plant equipment

Seawater cooling systems

Marine heat exchangers

Underwater surveillance equipment

The Soviet Union pioneered the use of titanium in submarine construction, developing techniques for forging titanium in huge vacuum tubes. Modern deep-sea exploration vehicles rely heavily on titanium for pressure hulls and structural components.

While cost has historically limited titanium in automotive industry applications, increasing demand for fuel efficiency and performance is driving adoption. Research shows that every 10% reduction in vehicle weight saves 8-10% in fuel consumption and reduces exhaust emissions by 10%.

High-performance exhaust systems (lighter and more durable than stainless steel)

Engine valves and valve springs

Connecting rods in racing engines

Suspension components

Turbocharger components

Fasteners and bolts

Manufacturers like Corvette have introduced titanium intake valves in models like the Z06's LT4 engine. Racing teams extensively use titanium for weight reduction without sacrificing strength.

The global titanium in automotive market is projected to reach $0.3 billion by 2030, growing at a CAGR of 4.0%. As production costs decrease and manufacturing techniques improve, titanium use in mainstream vehicles is expected to increase significantly.

Titanium is emerging as a critical material for clean energy and power generation, with applications spanning from traditional nuclear power to cutting-edge hydrogen fuel cells.

Nuclear Energy: Reactor components, nuclear waste storage containers, and fuel rod cladding

Geothermal Power: Heat exchangers and piping systems that withstand high temperatures and corrosive geothermal fluids

Hydrogen Production: Electrolysis equipment and fuel cell components

Solar Energy: Structural components and corrosion-resistant hardware

Wind Turbines: Lightweight structural elements and corrosion-resistant fasteners

Power Plants: Condenser tubes and cooling systems

The material's ability to withstand extreme temperatures (both high and low) and resist corrosion from various energy production processes makes it increasingly valuable as the world transitions to sustainable energy sources.

Surprisingly, only about 5% of mined and synthetic titanium minerals are used to produce titanium metal. The remaining 95% becomes titanium dioxide (TiO₂), a brilliant white pigment with remarkable opacity and brightness.

Paints and coatings (providing superior coverage and brightness)

Plastics and polymers (for whiteness and UV protection)

Paper manufacturing (for opacity and brightness)

Food products (as E171 food coloring)

Cosmetics and sunscreens (for UV protection and pigmentation)

Pharmaceuticals (tablet coatings)

Sporting Equipment: Golf club heads (the #1 consumer of titanium in sporting goods), tennis rackets, bicycle frames, lacrosse sticks, and baseball bats

Eyewear: Lightweight, hypoallergenic eyeglass frames

Watches: Durable, scratch-resistant watch cases

Consumer Electronics: Apple's PowerBook line and iPhone 15 Pro feature titanium bodies

Cookware: High-end pots and pans with excellent heat distribution

Tools: Lightweight hammers, knife handles, and flashlight bodies

Titanium bicycle frames represent the pinnacle of cycling technology. The world's lightest bicycle weighs only 6 lbs (compared to 30 lbs for average bikes and 15 lbs for racing bikes), thanks to its titanium structure.

Titanium's unique aesthetic properties—its natural luster and ability to display vibrant colors through anodization—combined with its structural capabilities make it attractive for architectural and artistic applications.

Guggenheim Museum Bilbao: Perhaps the most famous example, sheathed in titanium panels designed by Frank Gehry

Cerritos Millennium Library: Features titanium cladding

Monument to Yuri Gagarin: The 40-meter (131-foot) memorial in Moscow celebrating the first human in space

Monument to the Conquerors of Space: Another iconic titanium structure in Moscow

Olympic Torch Cauldron: Selected for its modern image and beautiful heat-treated colors

Titanium has been used for stabilization and repair of historic buildings, including the 2008 structural work on the Leaning Tower of Pisa in Italy, where its strength and corrosion resistance help preserve the monument for future generations.

Titanium Industries donated titanium panels for a 9/11 Memorial Monument commemorating victims of the Twin Towers tragedy, demonstrating the material's symbolic and practical value.

Titanium has become increasingly popular in jewelry due to its unique properties and aesthetic appeal.

Hypoallergenic (ideal for people with metal sensitivities)

Extremely durable and scratch-resistant

Lightweight for comfortable wear

Can be anodized to produce vibrant colors without dyes

Corrosion-resistant (won't tarnish or corrode)

Can be alloyed with gold to create durable 24-karat jewelry

Applications: Rings, bracelets, necklaces, earrings, and body jewelry. Titanium rings are particularly popular for wedding bands due to their durability and symbolic strength.

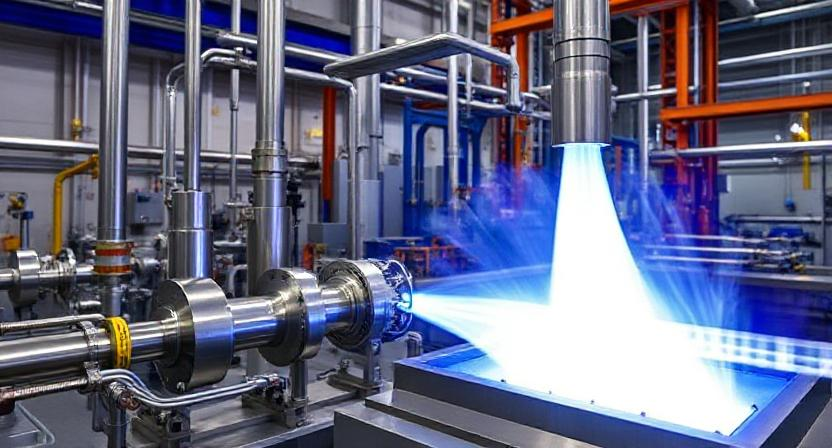

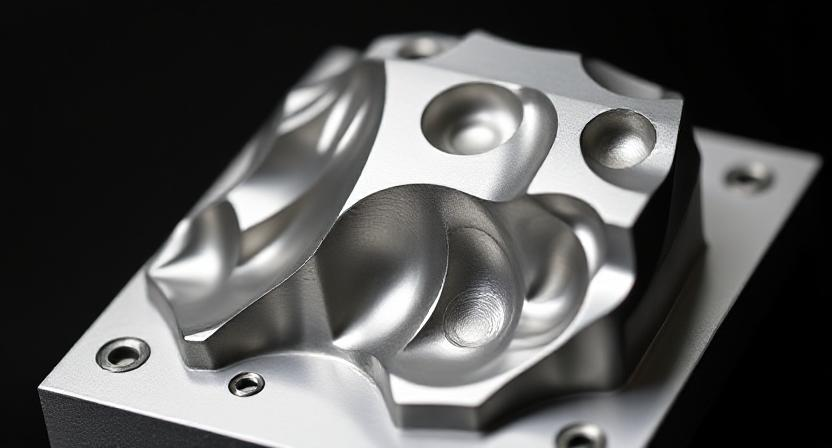

The emergence of additive manufacturing (3D printing) represents one of the most exciting developments in titanium usage. Titanium powders enable the production of complex geometries impossible with traditional manufacturing.

Laser Powder Bed Fusion (LPBF): Also known as Selective Laser Melting (SLM)

Electron Beam Melting (EBM): Uses electron beams to melt titanium powder

Binder Jetting: Bonds powder particles with adhesive

Direct Energy Deposition: Builds parts by melting material as it's deposited

Complex geometries with internal channels and lattice structures

Reduced material waste compared to subtractive manufacturing

Rapid prototyping and customization

Optimized weight reduction through topology optimization

Near-net-shape production reducing machining requirements

Aerospace: Custom brackets, engine components, structural parts

Medical: Patient-specific implants, surgical guides, prosthetics

Automotive: High-performance engine components, custom parts

Industrial: Specialized tooling, heat exchangers, custom fasteners

Market Growth: The global titanium market is projected to grow at approximately 4.5-6% CAGR through 2033, driven significantly by advances in additive manufacturing and increased aerospace and medical demand.

Beyond aerospace, titanium serves critical roles in defense applications where failure is not an option.

Armor plating for vehicles and personnel

Naval vessel components (especially submarines)

Military aircraft structures

Ballistic protection systems

Weapons systems components

Communication equipment housings

Missile casings and components

Titanium acts as a getter material in ultra-high vacuum systems, with titanium sublimation pumps removing trace gases.

Sputtering targets for semiconductor manufacturing and thin-film deposition.

When 6,000 stainless steel bolts securing the climbing track in Ton Sai, Thailand began corroding and breaking under body weight, metallurgists determined that only titanium bolts could be trusted with climbers' lives. Approximately 2,000 climbers use this track weekly, and a charity was established to replace all bolts with titanium along the entire route.

Research into titanium-based complexes for cancer treatment represents an emerging medical application.

Titanium's corrosion resistance makes it ideal for long-term nuclear waste containment.

Understanding what titanium is used for requires knowing when it outperforms alternatives:

| Comparison | Titanium Advantages | Other Metal Advantages | Best Use Case |

|---|---|---|---|

| Titanium vs. Stainless Steel | Stronger, lighter, superior corrosion resistance in chloride environments | Steel is more economical and easier to machine | Marine environments, medical implants, aerospace |

| Titanium vs. Aluminum | Stronger, maintains properties at higher temperatures, better corrosion resistance | Aluminum is less expensive and easier to machine | High-temperature applications, structural components |

| Titanium vs. Steel | Equivalent strength at roughly half the weight | Steel is more economical for general applications | Weight-critical applications, corrosive environments |

How is titanium made is a complex process that contributes to its cost:

Mineral Extraction: Titanium is extracted from minerals like rutile and ilmenite

Purification: The Kroll process converts titanium ore to titanium sponge

Melting: Vacuum arc remelting produces titanium ingots

Fabrication: Forging, rolling, and machining create final products

Powder Production: For additive manufacturing, ultrasonic atomization creates spherical titanium powder

Q: Is black anodized titanium expensive?

A: While the initial cost of titanium and the anodizing process can be higher than for other materials like aluminum or steel, the long-term durability and lack of need for replacement often make it a more cost-effective solution over the product's lifespan.

Q: How do you care for black anodized titanium?

A: It is very low maintenance. Cleaning with a soft cloth and mild soap is usually all that is needed. Avoid abrasive cleaners that could potentially scratch the surface.

Q: Will the black color fade over time?

A: The color is exceptionally stable and UV resistant. Unlike some dyed finishes, the black from this type of anodizing will not fade from exposure to sunlight.

Titanium is more than just a material; it's a high-performance solution that enhances the already impressive properties of titanium. Offering a rare blend of strength, lightness, corrosion resistance, and visual appeal, it provides a competitive edge in product design and engineering. As industries continue to push the boundaries of performance and longevity, the demand for advanced materials like titanium is set to grow, solidifying its place as a cornerstone of modern manufacturing.