Natural titanium metal color is a lustrous silver-gray, often with a subtle bluish hue, formed by a thin, protective oxide layer.

Vibrant titanium colors are achieved through anodization, an electrochemical process that grows a precise oxide layer on the surface.

These colors are not dyes or pigments but result from thin-film interference, where light waves interact with the oxide layer, similar to a soap bubble.

Different voltages applied during anodization create varying oxide thicknesses, leading to a spectrum of colors from bronze and gold to blue, purple, and green.

Colored titanium is highly valued in jewelry, medical implants, aerospace, and automotive industries for its aesthetic appeal, biocompatibility, and enhanced corrosion resistance.

For years, I've watched engineers and designers gravitate towards titanium. It's not just hype. This metal offers an incredible mix of strength, lightness, and resistance to corrosion that few other materials can match. But there's another dimension that truly captures attention: its remarkable ability to display a spectrum of colors.

We're talking about the captivating world of titanium metal color. It's a subject that goes beyond simple aesthetics, touching on the very science of how light interacts with matter. This isn't about paint; it's about physics and chemistry dancing together.

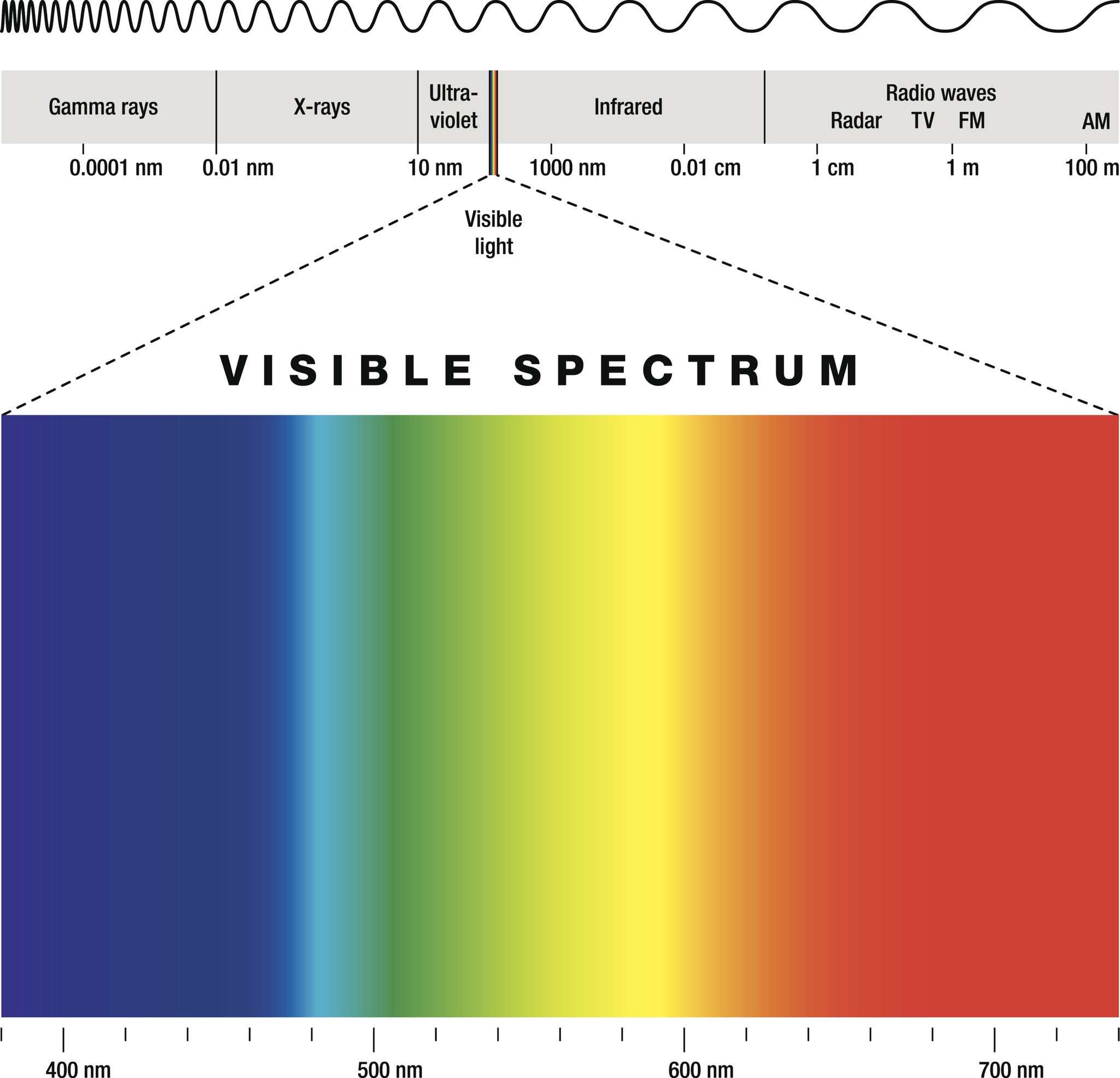

Now, here’s the deal: when most people think of colored metals, they imagine dyes or coatings. That's true for many materials, but titanium plays by different rules. The magic behind titanium's vibrant hues lies in a phenomenon called thin-film interference.

Think of an oil slick on water or a soap bubble shimmering in the sun. The colors you see aren't pigments; they're the result of light waves reflecting off different surfaces of a very thin film and interfering with each other. Titanium works the same way.

On titanium, this thin film is a transparent oxide layer. By precisely controlling the thickness of this layer, we can dictate which wavelengths of light are amplified and which are canceled out, creating the perceived color. It's quite literally an optical illusion, but a very stable and beautiful one.

Before any processes are applied, what does raw titanium look like? In its purest form, titanium presents as a lustrous, silvery-gray metal. You might even catch a subtle bluish tinge, especially in certain lighting conditions.

This natural color is due to a very thin, passive oxide layer that forms instantly when titanium is exposed to air. This layer, typically only a few nanometers thick, is what gives titanium its incredible corrosion resistance. It's understated, yet undeniably sophisticated.

I remember receiving my first batch of pure titanium sheets decades ago. That unadorned, almost stoic silver-gray had a beauty all its own. It hinted at the strength and purity within, a canvas waiting for transformation.

The real spectacle of titanium metal color comes alive through a process called anodization. This isn't some complex, secret alchemy; it’s a controlled electrochemical reaction. Here's how it generally works:

Preparation: First, the titanium piece must be meticulously cleaned to remove any oils, dirt, or surface contaminants. This ensures a uniform oxide layer.

Electrolyte Bath: The cleaned titanium is then submerged in an electrolyte solution. Common choices include dilute sulfuric or phosphoric acid.

Electrical Current: An electric current is passed through the setup. The titanium acts as the anode (positive electrode). This causes oxygen ions from the electrolyte to bond with the titanium surface, growing the oxide layer.

Voltage Control: The critical step is adjusting the voltage. The thickness of the oxide layer is directly proportional to the applied voltage. Higher voltages mean thicker oxide layers.

Color Formation: As the oxide layer thickens, it interferes with light differently, producing a distinct color. No dyes are involved; it's all about light waves.

It's a delicate dance between voltage and time, yielding results that are both functional and breathtaking. For more details on our processes, you can visit our Services page.

Expert Insight: "The precision required for consistent titanium anodization is immense. Even a slight fluctuation in voltage or electrolyte composition can shift the hue. It’s a testament to material science that we can achieve such reproducible, vibrant results."

The beauty of anodization is the sheer breadth of colors it can create. It's a true rainbow, all without a single drop of paint. Here's a general guide to the colors you can expect and the approximate voltage ranges:

Bronze/Light Brown: Low voltages, typically around 10-15V.

Gold/Yellow: Increasing the voltage slightly, often 15-20V.

Purple: Around 20-25V will start to yield rich purples.

Blue: Blues emerge as you go higher, from dark royal blues (25-30V) to lighter sky blues (30-40V).

Teal/Cyan: As voltage continues to climb, often in the 40-50V range.

Green: Higher voltages, typically 50-70V, produce various shades of green.

Pink/Magenta: Interestingly, these often appear at even higher voltages, sometimes in the 70-90V range.

It's important to note that exact hues can vary based on the specific alloy, surface finish, and electrolyte used. But the general progression remains consistent. No, you won't get a true red with this method, due to the physics of light interference.

While voltage is the primary driver, it's not the only player in the game. Several other factors influence the final titanium metal color:

Surface Finish: A highly polished surface will yield more vibrant, reflective colors. A matte or bead-blasted finish will result in softer, more pastel tones.

Titanium Purity: Pure titanium (Grade 1 or 2) generally produces the most brilliant and consistent colors. Alloys like Ti-6Al-4V (Grade 5) can also be anodized, but may show slight differences in hue or intensity.

Electrolyte Composition and Temperature: The type and concentration of the acid in the electrolyte bath, along with its temperature, can subtly affect the oxide layer's growth and crystalline structure, thus influencing the final color.

Pre-treatment: How the surface is prepared before anodization—whether through etching or other chemical treatments—can also impact the uniformity and vibrancy of the color.

It's a complex interplay, and mastering it requires both scientific understanding and a touch of artistry.

The aesthetic appeal of colored titanium isn't just for show. It serves practical purposes across countless industries. I've seen it used in ways I couldn't have imagined when I started in this field.

Jewelry and Fashion: From wedding bands to intricate earrings, anodized titanium offers hypoallergenic properties and vibrant, non-fading colors. It's a favorite for those seeking unique, durable pieces.

Medical Implants and Tools: Biocompatibility is key here. Colored titanium is used for color-coding surgical instruments or implants, making identification easier for surgeons and improving safety.

Aerospace and Automotive: Weight savings and corrosion resistance are paramount. Colored components can indicate specific grades, treatments, or even left/right orientation in critical assemblies.

Consumer Electronics: Think sleek phone cases, watch components, or specialized tools. The durability and unique aesthetic make it a premium choice.

The global demand for titanium, driven by these high-performance applications, continues to grow. It's a material that truly marries form and function.

Picking the right titanium color often comes down to the application. Are you aiming for subtle elegance or a bold statement? For example, a deep blue might be perfect for a sophisticated watch casing, while a vibrant green could make a piece of body jewelry truly stand out.

Consider the environment the piece will encounter. While anodized colors are durable, some applications, like rings, see more friction and wear. This is a crucial consideration for longevity. If you're looking for custom solutions, our team can help you explore the possibilities. Contact us for a consultation.

I've heard countless myths over the years about titanium and its colors. Let's set the record straight.

Myth: Titanium is naturally vibrant. Fact: As we discussed, raw titanium is silvery-gray. The vibrant colors are a result of surface treatment.

Myth: The color will fade or peel off like paint. Fact: Anodized titanium colors are not painted. They are an integral oxide layer. They won't fade from UV exposure or peel, though the layer can be scratched.

Myth: All titanium can be anodized to any color. Fact: While many colors are possible, achieving certain hues (like a true red) is not chemically or physically feasible through standard anodization. Also, pure titanium generally yields better results than some alloys.

Understanding these distinctions is vital, especially when making material choices for critical applications.

So, you've got a beautifully colored titanium piece. How do you keep it looking its best? It's simpler than you might think, but crucial.

Gentle Cleaning: Use warm water and a mild, non-abrasive soap (like dish soap). Gently wipe with a soft cloth or sponge. Avoid harsh chemicals, strong detergents, or abrasive cleaners.

Avoid Abrasives: Polishing cloths with abrasives or ultrasonic cleaners can damage the delicate oxide layer, dulling or even removing the color.

Protect from Scratches: While durable, the anodized layer is thin. Rings, in particular, are prone to scratching from daily friction. Store items separately to prevent contact with harder materials.

Beware of Chemicals: Hairspray, perfumes, chlorine, and even sweat can sometimes discolor anodized titanium, especially in blue hues. Wipe down pieces after wear.

A little care goes a long way in preserving the unique titanium metal color you've chosen.

Learn more about our commitment to quality.Absolutely. Titanium, even when anodized, is highly biocompatible and hypoallergenic. The coloring process doesn't involve dyes or pigments that could leach out and cause irritation, making it ideal for jewelry and medical implants.

Yes, it can. The old oxide layer can typically be removed through chemical or mechanical means, and the titanium can then be re-anodized to a new color. This is a common practice in customizing titanium pieces.

Yes, heat can also create a colored oxide layer on titanium, similar to anodization but less controlled. This is known as thermal oxidation. Different temperatures will produce different colors. However, for precise and consistent results, electrochemical anodization is preferred.

The physics of thin-film interference, which creates the colors, simply doesn't allow for a true red wavelength to be produced by titanium's oxide layer. Black titanium is typically achieved through other surface treatments like PVD (Physical Vapor Deposition) coatings, not anodization.

The journey of understanding titanium metal color is truly fascinating. From its humble beginnings as a silvery-gray workhorse, titanium has transformed into a canvas of incredible potential. The science of anodization allows us to manipulate light itself, creating a spectrum of stable, vibrant hues that enhance both the look and utility of this remarkable material.

As technology progresses, I expect to see even more innovative applications for colored titanium. It's a testament to human ingenuity and the endless possibilities that material science offers. The future for titanium's diverse color capabilities in design and engineering remains bright, quite literally.

Whether you need custom titanium parts or expert anodizing services, our team is here to help you achieve the perfect blend of performance and aesthetic appeal.

Get a Quote Today →