Anodized titanium, a material celebrated for its unique properties, offers a gateway to a world of advanced applications. This specialized process significantly enhances the natural characteristics of titanium, making it not only more versatile and durable but also visually striking. From high-performance aerospace components to critical medical devices and exquisite jewelry, the applications of anodized titanium parts are extensive and varied. This article delves into the science behind anodizing processes, explores the diverse types of titanium anodizing, and highlights why this material is an invaluable resource in numerous sectors.

At its core, anodizing titanium involves a sophisticated electrochemical process that fundamentally alters the metal's surface. By carefully applying an electric current while the titanium is submerged in an electrolyte solution, a controlled oxide film is formed. This layer on the surface acts as a protective barrier, which can be precisely manipulated to yield a spectrum of vibrant colors. Beyond its aesthetic appeal, this robust oxide layer dramatically improves the material's resistance to corrosion and significantly enhances wear resistance.

The anodizing process begins with submerging the titanium or titanium alloys in a carefully selected electrolyte solution. An electric current is then passed through the system, causing an electrochemical reaction that builds up an oxide film on the titanium surface. The voltage applied during this process is the key determinant of the oxide layer's thickness, which in turn dictates the resulting color. Unlike traditional dyeing or coating methods, the vibrant colors observed on anodized titanium are not pigments but rather the result of light interference within this transparent oxide layer. This phenomenon makes anodized titanium unique, as its colors are not only brilliant but also exceptionally durable and long-lasting, even under high temperature conditions.

Anodized titanium finds wide-ranging applications across numerous industries, primarily due to its exceptional combination of properties. Let's explore some of these key sectors:

In the medical field, anodized titanium is a revolutionary material. Its inherent biocompatibility makes it an ideal choice for a variety of surgical implants and medical devices. Specifically, anodized titanium is extensively used in joint replacements, dental implants, and precision surgical tools. The material's superior resistance to corrosion ensures the longevity and safety of these implants within the human body. Furthermore, the anodized layer can significantly reduce friction and improve the wear resistance of medical devices, contributing to better patient outcomes and device performance. This makes it a preferred material over alternatives like stainless steel in many critical applications.

Both the aerospace and automotive industries greatly benefit from the outstanding strength-to-weight ratio of anodized titanium. Components such as engine parts, critical fasteners, and structural elements are frequently manufactured from anodized titanium alloys. The lightweight nature of titanium contributes directly to improved fuel efficiency in aircraft and vehicles, while its remarkable resistance to extreme temperatures and corrosive environments ensures reliability and safety in demanding, high-performance conditions.

One of the most popular and visually appealing uses of anodized titanium is within the jewelry and fashion industry. Designers are drawn to its vibrant colors and hypoallergenic properties, making it an excellent choice for individuals with sensitive skin. Rings, necklaces, bracelets, and even watches are often crafted from this material. The combination of titanium's lightweight feel and its inherent durability makes it an ideal choice for everyday wear, offering both style and comfort.

In the electronics sector, anodized titanium is utilized in the manufacturing of various devices and components. Its ability to resist electromagnetic interference makes it suitable for electronic housings and connectors, ensuring signal integrity. Moreover, the vibrant colors achievable through anodizing make it highly appealing for consumer electronics, where aesthetics play a crucial role in product design and market appeal.

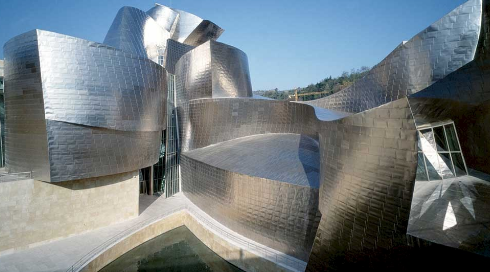

Architects and artists are increasingly incorporating anodized titanium into their creations, valuing both its aesthetic and functional attributes. Its excellent resistance to weathering makes it an ideal material for outdoor sculptures, building facades, and roofing. The capacity to produce a wide range of vibrant colors allows for highly creative and visually striking designs that stand the test of time.

The benefits of anodized titanium extend far beyond its diverse applications. Here are the primary reasons why it is such a highly sought-after and valuable material:

Superior Corrosion Resistance: The oxide film formed during anodizing acts as an exceptionally effective protective barrier, making anodized titanium highly resistant to corrosion. This property is crucial for applications in harsh environments, as it shields the metal from moisture, chemicals, and other corrosive agents, thereby extending its operational lifespan.

Enhanced Strength-to-Weight Ratio: Titanium is renowned for its impressive strength-to-weight ratio. The anodizing process further enhances this characteristic, resulting in anodized titanium components that are both incredibly strong and remarkably lightweight. This is particularly advantageous in industries where weight reduction is paramount, such as aerospace and high-performance automotive.

Exceptional Aesthetic Appeal: The ability to achieve a broad spectrum of vibrant colors is one of anodized titanium's most attractive features. From deep blues and greens to subtle golds and purples, these hues add a unique and sophisticated touch to any product. Crucially, unlike painted or coated surfaces, the colors embedded within the oxide film of anodized titanium do not peel, chip, or fade over time, maintaining their brilliance.

Biocompatibility and Hypoallergenic Properties: Anodized titanium is inherently biocompatible, meaning it is well-tolerated by the human body. This, combined with its hypoallergenic nature, makes it an excellent and safe choice for individuals with sensitive skin or for use in medical implants. This property is invaluable in the medical and jewelry industries, where direct and prolonged skin contact is common.

Reduced Friction and Improved Wear Resistance: The anodizing process can significantly enhance the surface hardness of titanium, leading to reduced friction and improved wear resistance. This is particularly beneficial in moving parts or components subjected to abrasive conditions, further extending the lifespan and performance of the anodized titanium parts.

Anodized titanium stands as a remarkable material, offering a wide-ranging array of applications across numerous critical industries. Its unique combination of properties—including superior corrosion resistance, an enhanced strength-to-weight ratio, exceptional aesthetic appeal through vibrant colors, biocompatibility, and improved wear resistance—makes it an invaluable resource for high-performance applications. As technological advancements continue to refine anodizing processes and explore new types of titanium anodizing, the potential uses for this extraordinary material are poised to expand even further, driving innovation and creativity in countless fields. Whether it's enhancing the visual appeal of jewelry, ensuring the safety of a dental implant, or improving the performance of aerospace components, anodized titanium continues to prove its worth, playing an increasingly vital role in shaping our modern world.