Titanium-Steel Clad Plate: The Ultimate Solution for Corrosion and Strength

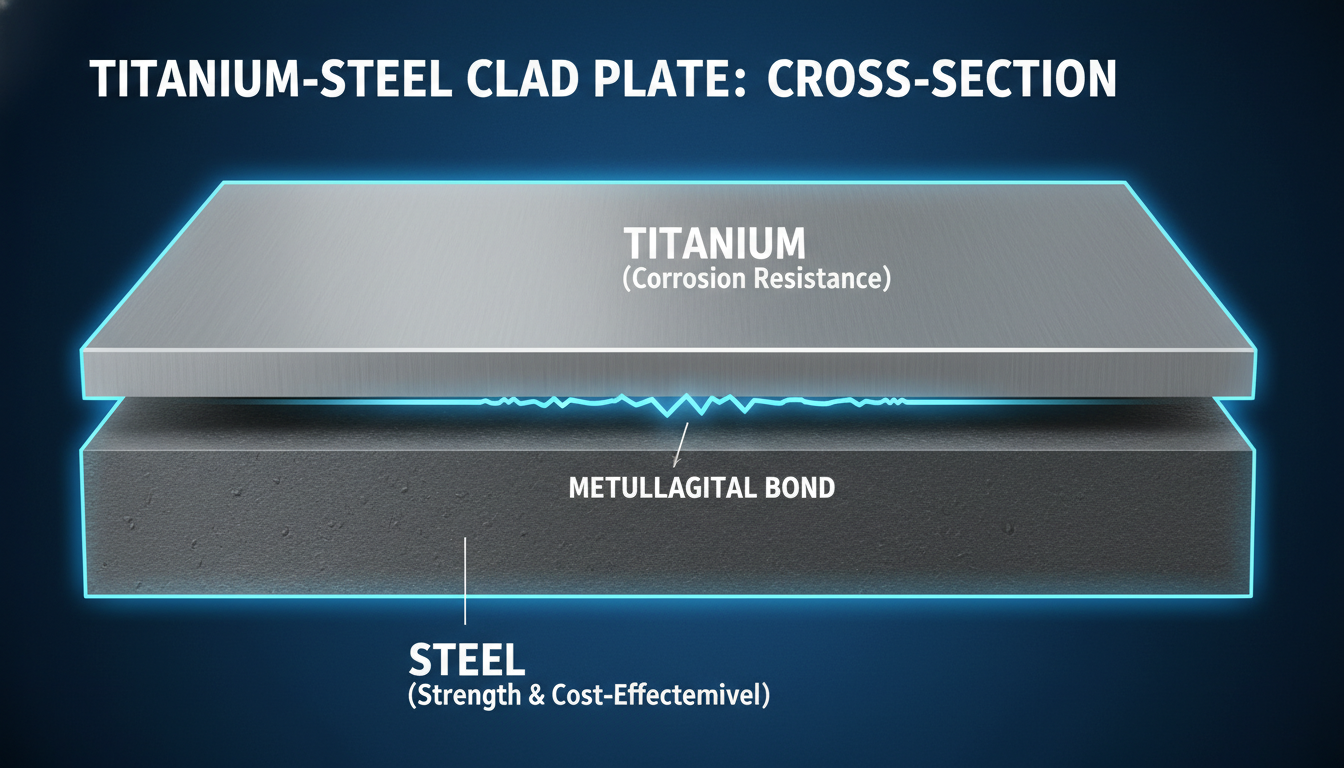

As a leading supplier of advanced metallic materials, we specialize in high-performance Titanium-Steel Clad Plates. This innovative bimetallic material is engineered to overcome the limitations of using pure titanium or pure steel in demanding industrial environments. By combining the exceptional corrosion resistance of titanium with the structural strength and cost-effectiveness of carbon or stainless steel, our clad plates offer an unparalleled solution for critical applications.

Titanium-Steel Clad Plate is a strategic material choice that delivers the best of both worlds. The cladding process creates a metallurgical bond that ensures reliable performance under extreme conditions.

Key Titanium-Steel Clad Plate benefits include:

Superior Corrosion Resistance: The titanium layer (cladding material) provides complete immunity to aggressive media, including chlorides, wet chlorine gas, and various acids, making it perfect for chemical processing equipment.

High Structural Integrity: The steel layer (base material) provides the necessary mechanical strength and rigidity to withstand high pressures and temperatures, particularly in pressure vessel construction.

Cost-Effectiveness: Utilizing a thin layer of expensive titanium bonded to a thicker, less expensive steel substrate significantly reduces material costs compared to using solid titanium plates.

Excellent Weldability and Fabrication: The steel backing allows for standard, cost-effective welding and fabrication techniques, simplifying the construction of large-scale equipment.

Our clad plates are manufactured to meet stringent international standards, ensuring reliability and performance. The choice of base and clad material combinations is crucial for optimizing the plate for its intended application.

| Clad Material (Corrosion Layer) | Base Material (Structural Layer) | Common Standards | Typical Applications |

|---|---|---|---|

| Commercially Pure Titanium (Gr. 1, Gr. 2) | Carbon Steel (SA516 Gr. 70, A36) | ASTM B898, ASME SB-898 | Chemical reactors, Desalination plants, Power generation. |

| Titanium Alloy (Gr. 5, Gr. 7, Gr. 12) | Stainless Steel (304/316L), Low Alloy Steel | JIS G3603, EN 13445 | Aerospace components, High-pressure heat exchangers, Oil & Gas. |

The primary method for producing our high-quality Titanium-Steel Clad Plates is Explosive Bonding. This process uses a controlled detonation to force the two metal surfaces together at high velocity, creating a true metallurgical bond with exceptional shear strength.

Process: A precisely calculated explosive charge is used to accelerate the titanium sheet onto the steel plate.

Result: A clean, strong, and void-free bond interface, ensuring excellent heat transfer and mechanical stability.

Our clad plate manufacturing process is governed by strict quality control protocols to guarantee the integrity of the bimetallic bond.

We prioritize quality control through:

Ultrasonic Testing: 100% inspection of the bond interface to detect any unbonded areas.

Shear Strength Testing: Verification of the metallurgical bond strength according to ASTM standards.

Chemical Analysis: Confirmation of the composition of both the titanium and steel layers.

Certifications: Our facility holds key certifications (e.g., ISO 9001, PED), guaranteeing full material traceability and compliance with global industry requirements.

The unique combination of properties makes Titanium-Steel Clad Plate indispensable in industries where corrosion and high pressure coexist.

Titanium clad steel is the material of choice for equipment handling highly corrosive media. This includes:

Pressure Vessels and Reactors: For synthesizing chemicals like PTA, urea, and acetic acid.

Heat Exchangers: Shell and tube heat exchangers where titanium tubes are welded to the titanium side of the clad tubesheet.

Storage Tanks: For long-term, safe storage of corrosive liquids.

In aggressive saltwater environments, the titanium layer provides lasting protection against corrosion, while the steel backing offers the necessary structural support for large marine structures and offshore platforms.

Used in components for flue gas desulfurization (FGD) systems and condensers in power plants, where resistance to acidic condensate and erosion is critical.

Selecting the correct clad plate requires careful consideration of the operating environment and mechanical requirements.

Determine Clad Material: Choose the titanium grade based on the corrosive medium (e.g., Gr. 2 for general corrosion, Gr. 7 for highly acidic environments).

Determine Base Material: Select the steel grade based on the required design pressure, temperature, and structural codes (e.g., SA516 Gr. 70 for pressure vessels).

Specify Thickness Ratio: Define the thickness of the titanium layer (typically 10-20% of the total thickness) and the steel layer to balance cost and performance.

Standards Compliance: Ensure the final product meets relevant standards like ASTM B898 or ASME Boiler and Pressure Vessel Code.

Successful fabrication of clad plates depends on specific techniques to maintain the integrity of both layers.

Welding: The titanium and steel layers must be welded separately. The steel side is welded first using standard procedures. The titanium side requires specialized welding with inert gas shielding (Argon) to prevent contamination and maintain corrosion resistance. A buffer layer (often Nickel or Stainless Steel) is sometimes used between the titanium and steel welds to prevent brittle intermetallic formation.

Forming: Clad plates can be formed (rolled, bent) using standard equipment, but care must be taken to avoid excessive strain that could compromise the bond interface.

Partner with us for your next project requiring the ultimate combination of corrosion resistance and strength. Our technical team is ready to assist you in selecting the optimal Titanium-Steel Clad Plate specification for your demanding application.

Get a Quote TodayContact our experts for detailed technical consultation and pricing.