The medical and surgical implant industry requires materials that are not only strong and lightweight but, most critically, possess excellent biocompatibility and corrosion resistance within the human body. The material must withstand physiological environments without degrading or causing adverse reactions.

Titanium and its alloys are the gold standard for these applications. They offer a unique combination of low density, high strength, and superior resistance to biological corrosion, making them ideal for long-term implantation where reliability and patient safety are paramount.

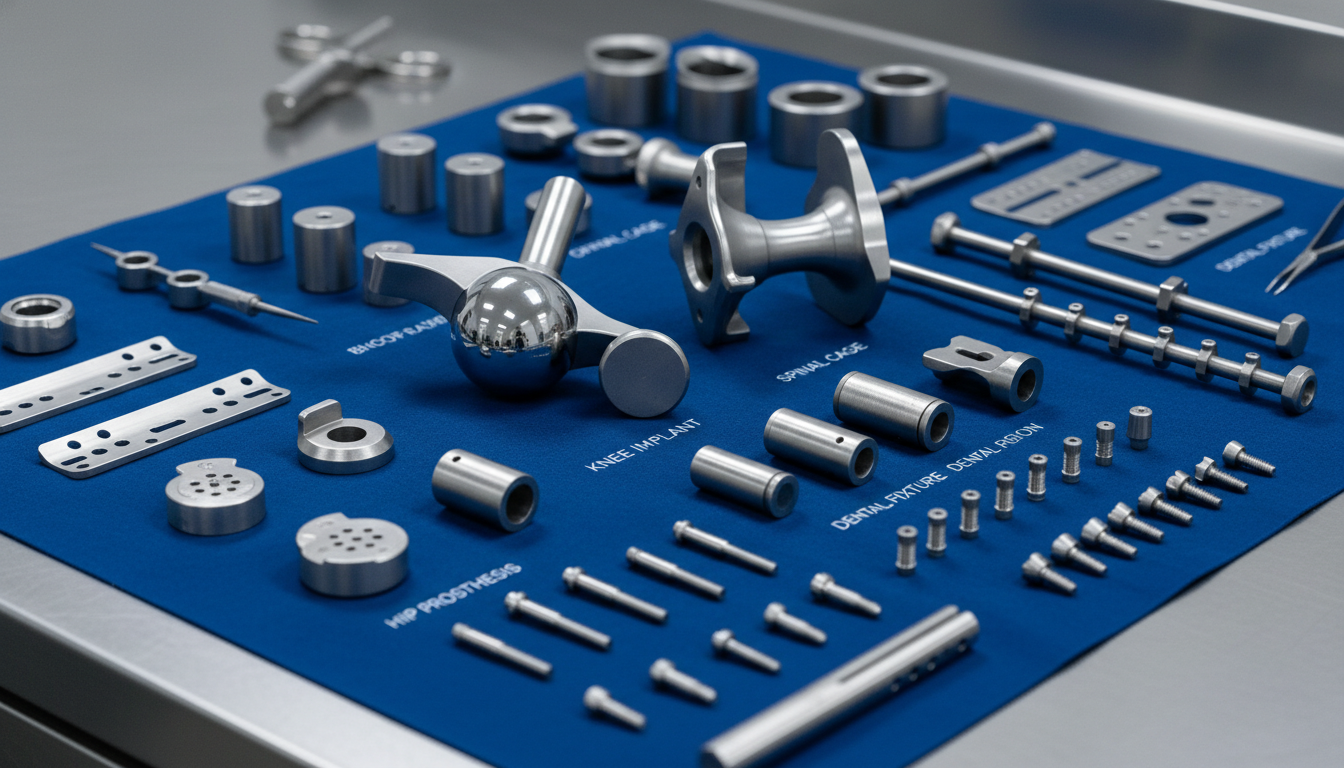

Our medical-grade titanium solutions are used in a wide range of critical applications:

Orthopedic Implants: Hip and knee replacements, bone plates, screws, and rods.

Dental Implants: Posts, abutments, and dental fixtures.

Cardiovascular Devices: Pacemaker casings and heart valve components.

Surgical Instruments: Lightweight, durable, and non-magnetic tools.

Titanium is supplied in forms suitable for high-precision manufacturing of implants and devices:

| Titanium Product Form | Application in Medical Industry |

|---|---|

| Forgings | Load-bearing components like hip stems and knee joints. |

| Machined Parts | Precision screws, plates, and dental implants. |

| Castings | Complex, near-net-shape components for reduced material waste. |

Medical applications require strict adherence to specialized ASTM standards, ensuring the highest purity and performance.

Need certified medical-grade titanium for your next implant design?

Request Material Certification Data| Applicable Material Form | Applicable ASTM Standard (US Standard) | Description | Applicable Grades (US Standard) |

|---|---|---|---|

| Titanium Plate | ASTM B265-06a | Titanium and Titanium Alloy Strip, Sheet, and Plate | Gr1, Gr2, Gr3, Gr4, Gr5 |

| Titanium Tube | ASTM B338-06a, ASTM B861-06a | Seamless and Welded Titanium and Titanium Alloy Tubes | Gr1, Gr2, Gr3, Gr4, Gr5 |

| Titanium Bar | ASTM B348-06a | Titanium and Titanium Alloy Bars and Billets | Gr1, Gr2, Gr3, Gr4, Gr5 |

| Titanium Wire | ASTM B863-06a | Titanium and Titanium Alloy Wire | Gr1, Gr2, Gr3, Gr4, Gr5 |

| Titanium Mesh | *Custom Specifications* | Used for cranial and facial reconstruction. | Gr1, Gr2 |

| Pure Titanium | ASTM F67-06 | Unalloyed Titanium for Surgical Implant Applications (UNS R50250, R50400, R50550, R50700) | Gr1, Gr2, Gr3, Gr4 |

| Ti-6Al-4V ELI | ASTM F136-02a | Wrought Ti-6Al-4V ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (R56401) | Gr5 ELI |

| Forged Ti-Alloy | ASTM F620-06 | Alpha-Beta Titanium Alloy Forgings for Surgical Implants | Gr5 ELI |

| Pure Titanium Wire | ASTM F1341-99 | Unalloyed Titanium Wire for Surgical Implant Applications (R50250, R50400, R50550, R50700) | Gr1, Gr2, Gr3, Gr4 |

Commercially Pure Titanium (Grades 1-4): These grades meet the requirements of ASTM F67. They are highly biocompatible and offer varying levels of strength (Gr4 being the strongest CP grade). They are primarily used for non-load-bearing implants, dental fixtures, and medical device casings where excellent formability is needed.

Grade 5 ELI (Ti-6Al-4V ELI): This alloy meets the stringent requirements of ASTM F136. The "ELI" (Extra Low Interstitial) designation signifies reduced oxygen and iron content, which enhances ductility and fracture toughness. It is the material of choice for high-stress, load-bearing orthopedic implants like hip and knee joints, offering superior strength-to-weight ratio and fatigue performance.

Titanium's unique properties have made possible the development of reliable, long-lasting implants that significantly improve patient quality of life.

Application: Total Hip Replacement

Challenge: Hip implants require a material that can withstand millions of load cycles over decades without fatigue failure, while remaining completely inert within the body to prevent rejection or inflammation.

Titanium Solution: Utilization of Grade 5 ELI (Ti-6Al-4V ELI) for the femoral stem and acetabular cup. The alloy's high strength and excellent fatigue properties ensure mechanical longevity, while its biocompatibility promotes osseointegration (bone growth onto the implant surface).

Outcome: Titanium implants have become the industry standard, offering decades of reliable service and minimizing the need for revision surgery.

Application: Dental Fixtures and Posts

Challenge: Dental implants must integrate seamlessly with the jawbone and withstand significant chewing forces, all while maintaining absolute purity to ensure successful osseointegration.

Titanium Solution: Use of Commercially Pure Titanium (Grades 2 and 4) bars and billets, manufactured to ASTM F67 standards, for the implant post. The material's ability to bond directly with bone tissue is unmatched.

Outcome: Titanium dental implants boast a success rate exceeding 95%, providing a permanent, stable, and aesthetically pleasing solution for tooth replacement.

All medical titanium products are manufactured under strict quality control to meet the rigorous requirements of ASTM F67, ASTM F136, and other relevant international standards. Traceability and material purity are guaranteed, ensuring the highest level of safety and performance for surgical applications.

By choosing our medical-grade titanium, you are partnering with a supplier committed to the highest standards of material quality for life-critical applications.

Disclaimer: The selection of medical-grade materials must comply with all local and international regulatory requirements and should be verified by a qualified biomedical engineer.