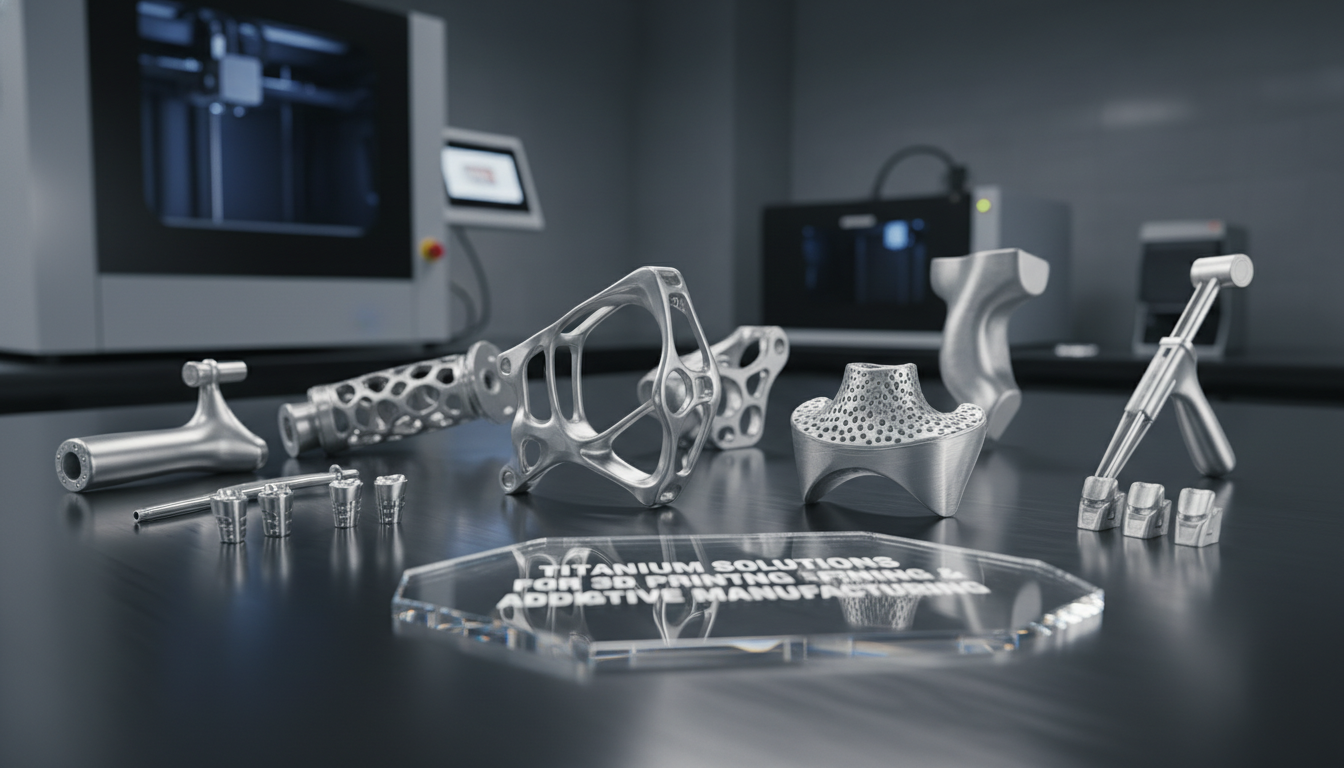

Additive Manufacturing (3D Printing) has revolutionized how complex, high-performance components are created. In this field, Titanium is the material of choice, enabling the production of parts with intricate geometries, reduced weight, and superior mechanical properties that are impossible to achieve with traditional subtractive methods.

The core requirements for titanium in 3D printing are a combination of low specific gravity (lightweight), high strength, and exceptional corrosion resistance. These properties make titanium 3D-printed parts indispensable in aerospace, medical implants, and high-end automotive sectors.

We supply the essential titanium materials required for various 3D printing technologies, ensuring optimal print quality and material integrity:

| Feedstock Form | Primary 3D Printing Technology | Key Properties Utilized |

|---|---|---|

| Titanium Powder | Selective Laser Melting (SLM), Electron Beam Melting (EBM), Binder Jetting | High purity, spherical morphology, controlled particle size distribution, and flowability. |

The following table details the primary titanium forms used in 3D printing, along with their corresponding ASTM standards and applicable grades:

| Titanium Product Form | Applicable ASTM Standard | Description | Applicable Grades |

|---|---|---|---|

| Titanium Rod / Bar | ASTM B348-06a | Titanium and Titanium Alloy Bar and Billet (Feedstock for WAAM/DED) | Gr1, Gr2, Gr5 |

| Titanium Powder | (Proprietary/AMS Standards) | High-Purity Titanium Powder for Additive Manufacturing | Gr1, Gr2, Gr5 |

Grade 1 (Gr1): Commercially Pure (CP) titanium, offering excellent ductility and the highest level of corrosion resistance, often used in medical devices and chemical processing equipment.

Grade 2 (Gr2): The standard CP grade, providing a good balance of strength and corrosion resistance, suitable for general industrial 3D printing applications.

Grade 5 (Gr5) / Ti-6Al-4V: The most widely used titanium alloy in 3D printing. This alpha-beta alloy offers an outstanding combination of high strength, low weight, and biocompatibility, making it essential for aerospace structural parts and medical implants.

Titanium 3D printing has enabled unprecedented design freedom and performance gains across several high-tech industries.

Industry: Medical/Orthopedics

Challenge: Creating patient-specific, porous orthopedic implants (e.g., hip cups, spinal cages) that promote bone ingrowth while maintaining high strength and biocompatibility.

Titanium Solution: Utilizing Grade 5 (Ti-6Al-4V) Titanium Powder in SLM/EBM processes. Additive manufacturing allows for the creation of complex lattice structures that mimic natural bone porosity, which is impossible with traditional machining.

Outcome: Faster patient recovery, reduced surgical time, and superior long-term integration of the implant due to the optimized porous structure and the inherent biocompatibility of Gr5 titanium.

Industry: Aerospace

Challenge: Reducing the weight of complex engine brackets and airframe components to improve fuel efficiency, while ensuring the parts can withstand extreme thermal and mechanical stresses.

Titanium Solution: Printing complex, consolidated parts using Grade 5 Titanium Powder via SLM. This approach reduces the number of individual parts, eliminates costly tooling, and allows for topology optimization to remove non-essential material.

Outcome: Significant weight reduction (up to 50% in some cases) compared to machined parts, reduced assembly complexity, and improved performance through optimized thermal management.

The quality of the titanium feedstock is paramount for successful 3D printing. We ensure that all our titanium products meet the highest standards for purity, consistency, and traceability.

Feedstock Certification: Our Titanium Powder is produced under strict quality control, with certified chemical composition, particle size distribution, and flow characteristics to ensure optimal print parameters and final part density.

Material Specifications: We comply with stringent standards such as ASTM B348 for our bar/rod feedstock, and relevant aerospace and medical standards (e.g., AMS specifications) for our powders, guaranteeing material integrity.

Traceability: Every batch of titanium powder and rod is fully traceable, from the raw material melt to the final product, providing our customers with complete confidence in their critical components.

By choosing our titanium solutions, you are investing in the material quality and consistency required to push the boundaries of additive manufacturing.

Unlock the potential of 3D printing with high-performance, certified titanium feedstock.

Request a Quote or Consultation Today