The hydrometallurgy and electroplating sectors, including the production of copper, nickel, cobalt, and gold, rely on highly efficient and stable electrolytic processes. These processes involve strong acidic or corrosive electrolyte solutions, which demand materials that offer both exceptional corrosion resistance and high electrical conductivity.

Traditional materials often suffer from rapid degradation, leading to metal contamination, reduced current efficiency, and frequent equipment replacement. Titanium is the ideal material for these applications, providing a stable, long-lasting, and highly conductive substrate for anodes and cathodes.

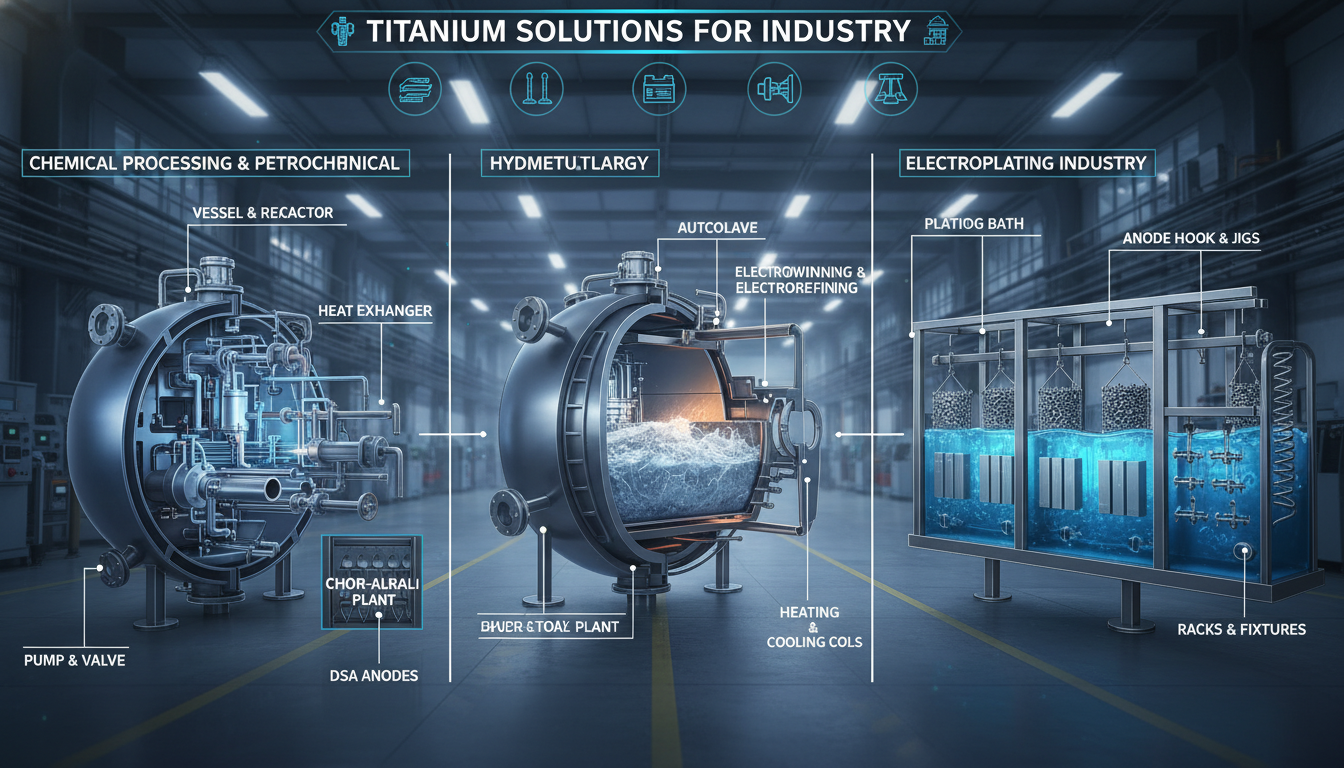

Our titanium solutions are critical for optimizing the following major industrial processes:

Hydrometallurgy and Gold Smelting: Equipment for leaching and recovery processes.

Electrolysis of Copper, Nickel, and Cobalt: Durable cathode starter sheets and anodes for metal refining.

Electrolytic Copper Foil Production: High-purity titanium drums and equipment for thin copper foil manufacturing.

Precious Metal Coating: Substrates for dimensionally stable anodes (DSA) with precious metal coatings.

Titanium is fabricated into specialized forms to serve as the core components in electrolytic cells, ensuring maximum efficiency and minimal maintenance.

| Titanium Product | Application in Hydrometallurgy & Electroplating |

|---|---|

| Cathode Starter Sheets | Used in copper, nickel, and cobalt electrolysis for metal deposition and easy stripping (lifting) of the refined metal foil. |

| Anodes | Dimensionally Stable Anodes (DSA) and insoluble anodes for various electrolytic processes. |

| Piping and Chemical Equipment | Corrosion-resistant transfer lines and vessels for handling aggressive electrolyte solutions. |

| Foil Lifting Machines | Components requiring high corrosion resistance and precision in copper foil production. |

The selection of the appropriate titanium grade is crucial for optimal performance and cost efficiency. Our solutions primarily utilize commercially pure titanium and low-alloyed grades known for their superior corrosion resistance.

Need help selecting the perfect titanium grade or product form for your specific electrolytic process?

Download Our Titanium Grade Selection Guide| Applicable Material Form | Applicable ASTM Standard (US Standard) | Description | Applicable Grades (US Standard) |

|---|---|---|---|

| Titanium Plate | ASTM B265-06a | Titanium and Titanium Alloy Strip, Sheet, and Plate (Used for Cathode Starter Sheets) | Gr1, Gr2, Gr11, Gr12 |

| Titanium Mesh | Custom Specifications | Expanded metal mesh used as the substrate for DSA (Dimensionally Stable Anodes). | Gr1, Gr2 |

| Titanium-Copper Clad Bar | Custom Specifications | Used for anode/cathode hangers and conductors, combining titanium's corrosion resistance with copper's high conductivity. | Gr1, Gr2 |

Grade 1 (Gr1): The purest CP titanium, offering the highest ductility and excellent corrosion resistance. It is often used for the base material of cathode starter sheets and foil lifting equipment where high purity is essential to prevent contamination.

Grade 2 (Gr2): The standard CP titanium grade, providing an optimal balance of strength, weldability, and superior corrosion resistance in most electrolyte solutions. It is the most common choice for titanium mesh substrates and general equipment.

Grade 11 (Gr11): A palladium-enhanced CP titanium alloy, offering improved crevice corrosion resistance in reducing acid environments. This is critical in areas where the anode/cathode assembly meets the busbar or other tight joints.

Grade 12 (Gr12): A titanium-nickel-molybdenum alloy, providing superior high-temperature strength and exceptional resistance to crevice corrosion. It is used in the most aggressive, high-temperature electrolytic baths where localized corrosion is a major concern.

The implementation of titanium has revolutionized the efficiency and longevity of metal refining and electroplating operations globally.

Industry: Copper Electrolysis (Electrowinning)

Challenge: Traditional stainless steel cathode blanks often required frequent surface preparation and had a limited lifespan, leading to high operational costs and inconsistent copper quality.

Titanium Solution: Adoption of Grade 1 Titanium Cathode Starter Sheets. The smooth, passive surface of titanium allows for easy, clean stripping of the deposited copper, minimizing labor and maximizing the quality of the refined metal.

Outcome: Significant reduction in labor costs associated with stripping, elimination of contamination, and an increase in the purity and consistency of the final copper product, leading to a rapid return on investment.

Industry: Gold Smelting and Precious Metal Recovery

Challenge: Highly corrosive cyanide and chloride solutions used in gold recovery processes rapidly destroy conventional anode materials, requiring constant replacement and causing process interruptions.

Titanium Solution: Implementation of Titanium Mesh substrates coated with precious metal oxides (DSA). The titanium provides a stable, corrosion-proof base, while the coating ensures catalytic activity.

Outcome: The titanium-based DSA anodes achieved a service life of several years, dramatically reducing the frequency of anode replacement and maintaining stable cell voltage and current efficiency throughout the process.

All titanium products supplied for the hydrometallurgy and electroplating industries adhere strictly to international quality and material specifications. Compliance with the latest revisions of the American Society for Testing and Materials (ASTM) standards ensures material integrity, traceability, and performance reliability in critical applications.

By choosing our titanium solutions, you are investing in equipment longevity, reduced maintenance costs, and enhanced operational safety in the most challenging electrolytic environments.

Disclaimer: The specific grade and product form selection should always be verified by a materials engineer based on the exact chemical composition, temperature, and pressure of the operating environment.