The marine and offshore industries face one of the most aggressive corrosive environments on Earth: seawater. Traditional materials like copper-nickel alloys and stainless steel are susceptible to rapid corrosion, erosion, and biofouling, leading to frequent maintenance, reduced efficiency in heat transfer, and costly downtime in critical systems like desalination plants and coastal power stations.

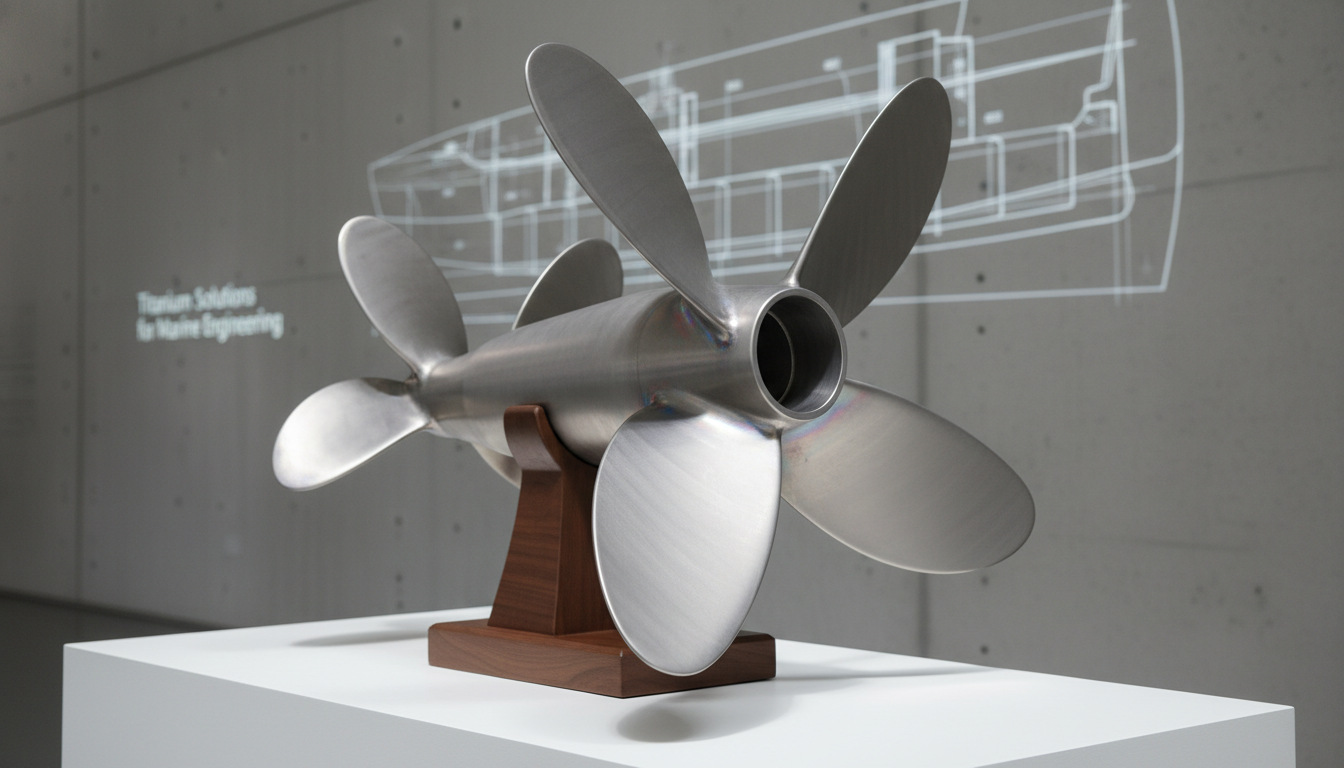

Titanium is the definitive solution for these challenges. It is virtually immune to seawater corrosion, including crevice corrosion and pitting, and its passive oxide layer naturally resists biofouling. This ensures high strength, low weight, and long-term reliability in all marine applications.

Our titanium solutions are essential for the longevity and efficiency of the following major sectors:

Marine Engineering: Submarine hulls, deep-sea equipment, and offshore structures.

Seawater Aquaculture: Corrosion-free cages and piping systems.

Seawater Desalination: Critical components in Multi-Stage Flash (MSF) and Multi-Effect Distillation (MED) heat exchangers.

Coastal Power Stations: Condenser tubes and cooling water piping systems.

Titanium is supplied in forms optimized for marine construction and heat transfer efficiency:

| Titanium Product Form | Application in Marine & Offshore |

|---|---|

| Titanium Heat Exchangers | Condensers, evaporators, and cooling systems in power plants and desalination facilities. |

| Piping and Valves | Seawater intake and discharge pipelines, fittings, and valves. |

| Titanium Fences/Barriers | Protective structures in coastal environments and aquaculture. |

| Components | Fittings, flanges, and pump parts exposed to seawater. |

The selection prioritizes commercially pure grades for their excellent corrosion resistance and the Gr9 alloy for its superior strength and weldability.

Optimize your marine project with the right titanium alloy. Need material selection advice?

Download Our Marine Titanium Guide| Applicable Material Form | Applicable ASTM Standard (US Standard) | Description | Applicable Grades (US Standard) |

|---|---|---|---|

| Titanium Plate | ASTM B265-06a | Titanium and Titanium Alloy Strip, Sheet, and Plate | Gr1, Gr2, Gr5, Gr9 |

| Titanium Tube | ASTM B338-06a, ASTM B861-06a | Seamless and Welded Titanium and Titanium Alloy Tubes | Gr1, Gr2, Gr5, Gr9 |

| Titanium Bar | ASTM B348-06a | Titanium and Titanium Alloy Bars and Billets | Gr1, Gr2, Gr5, Gr9 |

| Titanium Wire | ASTM B863-06a | Titanium and Titanium Alloy Wire | Gr1, Gr2, Gr5, Gr9 |

| Titanium Mesh | Custom Specifications | Used for filtration and protective screens. | Gr1, Gr2 |

Grade 1 (Gr1) & Grade 2 (Gr2): These Commercially Pure (CP) grades are the primary choice for seawater applications. They offer virtually complete immunity to corrosion in natural seawater and brine solutions, making them ideal for heat exchanger tubes, piping, and structural components where high strength is not the overriding factor.

Grade 5 (Gr5) / Ti-6Al-4V: Used where high strength is required alongside excellent corrosion resistance, such as in deep-sea submersibles, high-stress fasteners, and structural components of offshore platforms.

Grade 9 (Gr9) / Ti-3Al-2.5V: Known as "half-six," this alloy offers medium strength, excellent cold workability, and superior corrosion resistance. It is often used for seamless tubing in heat exchangers and hydraulic lines where a balance of strength and formability is needed.

Titanium's reliability in seawater has led to its widespread adoption, ensuring long-term operational success in challenging environments.

Industry: Seawater Desalination (MSF/MED)

Challenge: Condenser tubes in desalination plants are constantly exposed to hot, high-salinity brine, which causes rapid pitting and failure in traditional copper-nickel and stainless steel tubes, leading to massive production losses.

Titanium Solution: Replacement of conventional tubes with Grade 2 Titanium Tube (ASTM B338). Titanium's complete resistance to brine corrosion and erosion allows for thinner wall tubes, improving heat transfer efficiency.

Outcome: Extended service life of the heat exchangers to over 30 years, zero corrosion-related failures, and sustained high thermal efficiency, significantly lowering the overall cost of water production.

Industry: Coastal Power Generation

Challenge: Cooling water intake systems and condensers are subject to biofouling and erosion from high-velocity seawater, reducing the efficiency of the power plant's cooling cycle.

Titanium Solution: Installation of Grade 2 Titanium Plate and Titanium Tube for the main condenser and piping. Titanium's smooth surface and passive layer naturally inhibit biofouling, and its hardness resists erosion.

Outcome: Maintained peak thermal efficiency without the need for frequent mechanical or chemical cleaning, resulting in lower operating costs and a stable power supply.

All titanium products supplied for marine and offshore applications adhere strictly to international quality and material specifications. Compliance with ASTM standards ensures material integrity, traceability, and performance reliability in critical infrastructure.

By choosing our titanium solutions, you are securing your investment against the harsh realities of the marine environment.

Disclaimer: The specific grade and product form selection should always be verified by a materials engineer based on the exact operating environment, flow rates, and regulatory requirements.