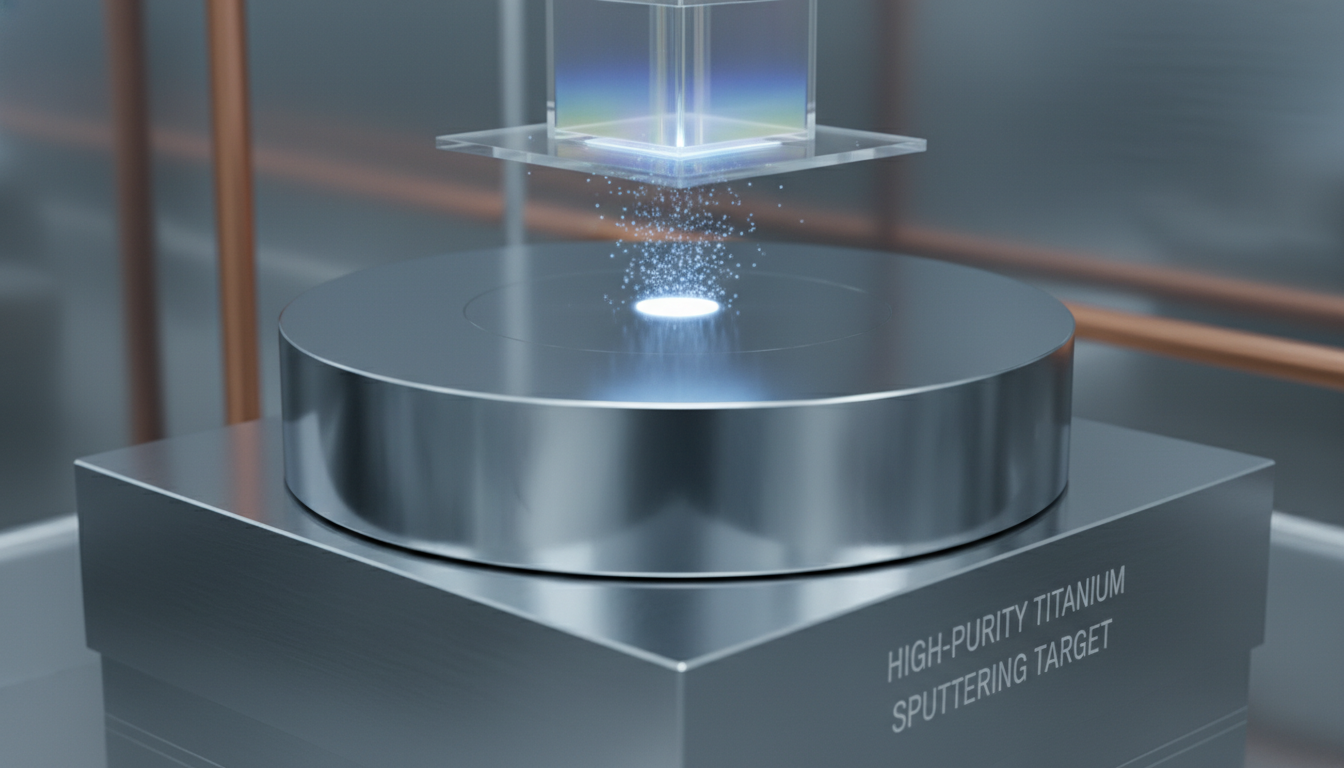

The coating industry, particularly in Physical Vapor Deposition (PVD) and thin film technology, demands materials of the highest purity and consistency. Titanium sputtering targets must not only be highly corrosion-resistant but also maintain exceptional material integrity to ensure uniform film thickness and prevent defects during the deposition process.

Titanium is a preferred material for sputtering targets due to its excellent corrosion resistance and its ability to form durable, high-quality thin films used in optics, electronics, and decorative coatings. Our focus is on providing ultra-high purity titanium to meet the stringent requirements of advanced coating applications.

Our high-purity titanium targets are critical for the following major industrial processes:

Decorative Coatings: Durable, aesthetic finishes for watches, jewelry, and consumer electronics.

Optical Coatings: Anti-reflective and protective layers for lenses and displays.

Semiconductor and Microelectronics: Barrier layers and interconnects in integrated circuits.

Tool Coatings: Hard, wear-resistant layers for cutting tools and molds (TiN, TiAlN).

We supply titanium in various forms optimized for different sputtering equipment and processes:

| Titanium Product Form | Application in Coating Industry |

|---|---|

| Titanium Plate Target | Planar sputtering systems for large-area deposition. |

| Titanium Tube Target | Rotary sputtering systems, offering higher material utilization and throughput. |

| Titanium Rod Target | Used in specific PVD equipment configurations. |

| Titanium Granules | Used as source material for evaporation coating processes. |

The purity of the titanium is the most critical factor, with Commercially Pure (CP) grades being the standard.

Need ultra-high purity titanium targets for your next PVD run?

Request Purity Certification Data| Applicable Material Form | Applicable ASTM Standard (US Standard) | Description | Applicable Grades (US Standard) |

|---|---|---|---|

| Titanium Plate | ASTM B265-06a | Titanium and Titanium Alloy Strip, Sheet, and Plate | Gr1, Gr2 |

| Titanium Tube | ASTM B338-06a, ASTM B861-06a | Seamless and Welded Titanium and Titanium Alloy Tubes | Gr1, Gr2 |

| Titanium Bar | ASTM B348-06a | Titanium and Titanium Alloy Bars and Billets | Gr1, Gr2 |

| Titanium Wire | ASTM B863-06a | Titanium and Titanium Alloy Wire | Gr1, Gr2 |

Grade 1 (Gr1): The highest purity Commercially Pure (CP) titanium. It is often the preferred choice for sputtering targets where minimal impurities are critical to the final film quality, especially in semiconductor and high-end optical applications.

Grade 2 (Gr2): The standard CP titanium grade, offering a balance of purity and mechanical properties. It is widely used for general decorative and functional coatings where high purity is important but the extreme requirements of microelectronics are not present.

The use of high-quality titanium targets is essential for achieving the performance and aesthetic requirements of modern coatings.

Industry: Optical and Display Manufacturing

Challenge: Producing ultra-thin, highly uniform titanium oxide (TiO2) films for anti-reflective coatings on high-resolution displays. Impurities in the target material can lead to defects and poor optical performance.

Titanium Solution: Utilization of Ultra-High Purity Grade 1 Titanium Plate Targets. The high purity ensures a stable sputtering process and a defect-free, high-quality final film.

Outcome: Consistent production of optical coatings that meet stringent industry standards for transparency, reflectivity, and durability.

Industry: Large-Area Architectural Glass Coating

Challenge: Traditional planar targets have lower material utilization and require frequent replacement, leading to high operational costs in large-scale coating operations.

Titanium Solution: Implementation of Grade 2 Titanium Tube Targets in rotary sputtering systems. The cylindrical shape allows for more uniform erosion and higher material utilization.

Outcome: Increased target utilization by over 50% and reduced downtime for target replacement, resulting in significant cost savings and improved production throughput.

All titanium sputtering targets are manufactured under strict quality control, focusing on material purity, density, and grain structure to ensure optimal sputtering performance. We adhere to relevant ASTM standards for material composition and dimensional tolerance.

By choosing our high-purity titanium targets, you are ensuring the consistency and quality of your thin film deposition processes.

Disclaimer: The selection of target material must be verified based on the specific PVD equipment, process parameters, and final film requirements.