The Challenge: Extreme Electrochemical Environments

The rapidly expanding New Energy sector, particularly in hydrogen production (electrolysis) and advanced battery systems, requires materials that can withstand the most aggressive electrochemical conditions. Components must exhibit exceptional corrosion resistance against strong acids and bases (electrolytes), maintain structural integrity under high current densities, and serve as a stable substrate for precious metal coatings (e.g., for catalytic activity).

Titanium, especially Commercially Pure (CP) grades, is the material of choice due to its ability to form a highly protective, passive oxide layer, making it virtually immune to corrosion in these harsh environments.

Our high-performance titanium products are engineered for the following critical New Energy applications:

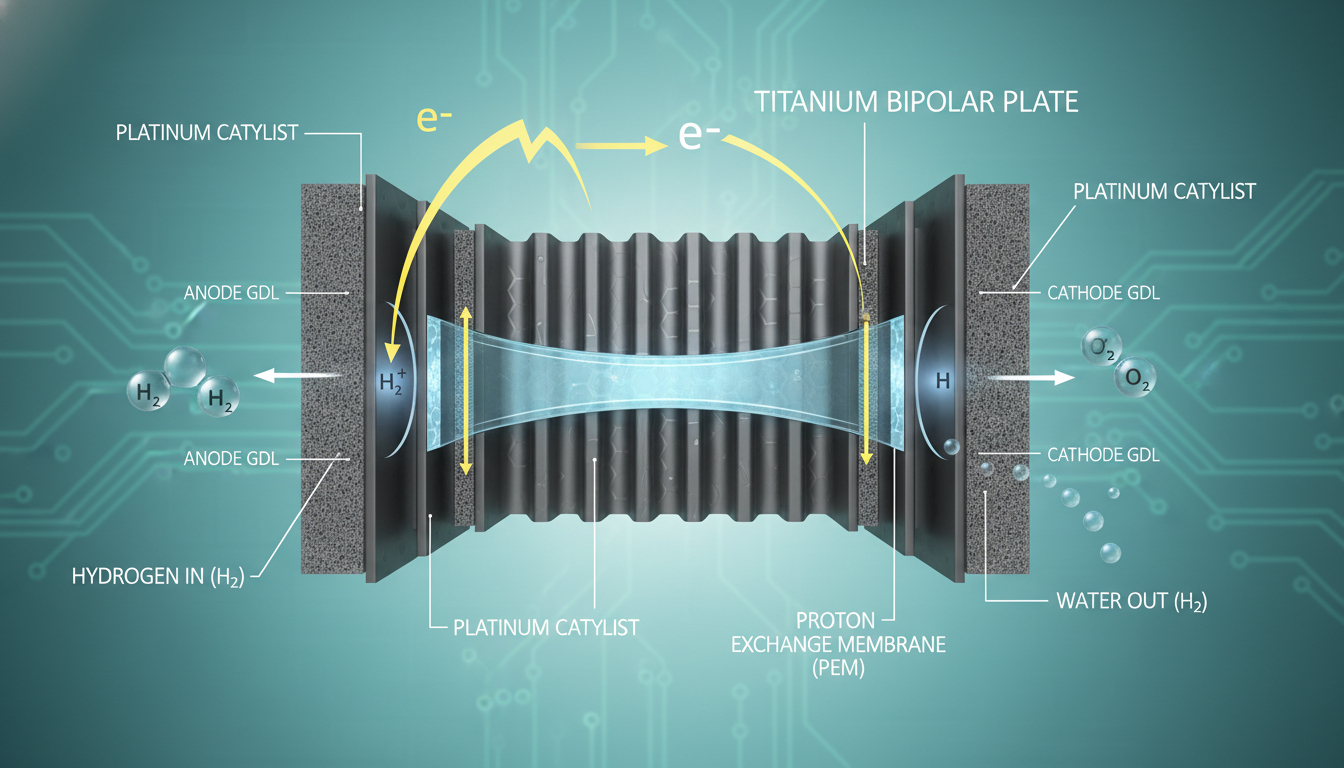

Hydrogen Production (Electrolysis): Used for anode and cathode substrates, bipolar plates, and cell components in Proton Exchange Membrane (PEM) and Alkaline Exchange Membrane (AEM) electrolyzers.

Battery Technology: Employed as current collectors, structural components, and electrode substrates in advanced battery chemistries, including flow batteries and certain lithium-ion systems.

Electrochemical Processing: Used in various other electrochemical cells where high corrosion resistance is mandatory.

Titanium is supplied in specialized forms to maximize efficiency and performance in electrochemical systems.

| Titanium Product Form | Key Application in New Energy | Key Features |

|---|---|---|

| Titanium Plate | Anode/Cathode Substrates, Bipolar Plates | Excellent corrosion resistance, ideal substrate for precious metal coatings (e.g., IrO2, RuO2). |

| Titanium Rod | Structural components, current leads, and connectors | High strength, low density, and reliable electrical conductivity. |

| Titanium Mesh | Gas diffusion layers, current collectors in flow batteries | High surface area, excellent current distribution, and lightweight. |

Our materials for New Energy applications adhere to stringent international quality and material specifications, ensuring optimal performance and longevity in critical systems.

| Applicable Material Form | Applicable ASTM Standard (US Standard) | Description | Applicable Grades (US Standard) |

|---|---|---|---|

| Plate, Sheet, and Strip | ASTM B265-06a | Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate | Gr1, Gr2 |

| Rod and Bar | ASTM B348-06a | Standard Specification for Titanium and Titanium Alloy Bars and Billets | Gr1, Gr2 |

Grade 1 (Gr1): Commercially Pure (CP) titanium, offering the highest ductility and superior corrosion resistance, particularly suitable for forming complex shapes like corrugated bipolar plates. It is the preferred choice for applications requiring a highly stable substrate for catalytic coatings.

Grade 2 (Gr2): The standard CP titanium grade, providing a slightly higher strength than Gr1 while maintaining excellent corrosion resistance. It is widely used for electrode substrates and structural components in electrochemical cells where a balance of strength and chemical inertness is required.

Titanium's reliability is a cornerstone of next-generation clean energy infrastructure.

Case Study 1: Enhanced Efficiency in PEM Electrolyzers

Industry: Green Hydrogen Production

Challenge: Bipolar plates in PEM electrolyzers operate in a highly acidic environment (low pH) and must maintain extremely low contact resistance with the catalyst layer over thousands of hours of operation.

Titanium Solution: Precision-formed Grade 1 Titanium Plate (ASTM B265) is used as the substrate for the bipolar plates. The titanium is coated with a thin layer of precious metal (e.g., gold or platinum) to further reduce contact resistance, leveraging titanium's stable oxide layer to prevent substrate degradation.

Outcome: Significant improvement in electrolyzer efficiency and durability, enabling cost-effective, long-term green hydrogen production.

Case Study 2: Durable Anodes for Chlor-Alkali Production

Industry: Chemical Processing (Electrochemical)

Challenge: Traditional anode materials rapidly degrade in the highly corrosive brine solution used in the chlor-alkali process, leading to frequent shutdowns and high maintenance costs.

Titanium Solution: Dimensionally Stable Anodes (DSA) are constructed using Grade 2 Titanium Mesh (or Plate) as the substrate, coated with a mixed metal oxide (MMO) catalyst. The titanium provides the necessary structural support and complete corrosion immunity.

Outcome: Drastically extended anode lifespan, reduced energy consumption, and continuous, reliable operation in one of the world's most demanding electrochemical processes.

Material consistency and surface quality are critical for the performance of titanium in electrochemical applications, especially for ensuring the adhesion and effectiveness of precious metal coatings.

Material Specifications: Our titanium products strictly comply with ASTM B265 and ASTM B348, ensuring precise chemical composition and mechanical properties.

Surface Preparation: We provide specialized surface treatments, including acid etching and blasting, to optimize the titanium substrate for the application of precious metal coatings, guaranteeing superior adhesion and electrochemical performance.

Traceability: Full batch traceability is maintained for all supplied material, ensuring quality control and reliability for mission-critical energy systems.

Titanium is essential for the longevity and efficiency of New Energy systems. Its unparalleled corrosion resistance in electrolytes, combined with its high strength and low density, ensures that your components will perform reliably for decades, minimizing downtime and maximizing return on investment in the clean energy transition.

Partner with us to power the future of New Energy with high-performance titanium solutions.

Request a Quote or Consultation TodayDisclaimer: The specific grade and product form selection should always be verified by a materials engineer based on the exact operating environment, electrolyte composition, and regulatory requirements.