In the field of electrochemistry, choosing the right anode material is crucial. It directly affects the efficiency and lifespan of the entire process. Platinized titanium anodes are an excellent material in this regard. This article will detail the benefits of using platinized titanium anodes, explaining why they are highly regarded in various electrochemical applications. Platinized titanium anodes consist of two parts: a titanium substrate and a thin layer of platinum coating. This combination brings together the advantages of both materials: the strength and corrosion resistance of titanium, and the excellent conductivity and catalytic properties of platinum. This unique combination makes platinized titanium anodes perform exceptionally well in electrochemical processes requiring high efficiency and long life. They can not only effectively transfer current but also resist erosion from harsh environments, ensuring the smooth progress of electrochemical reactions.

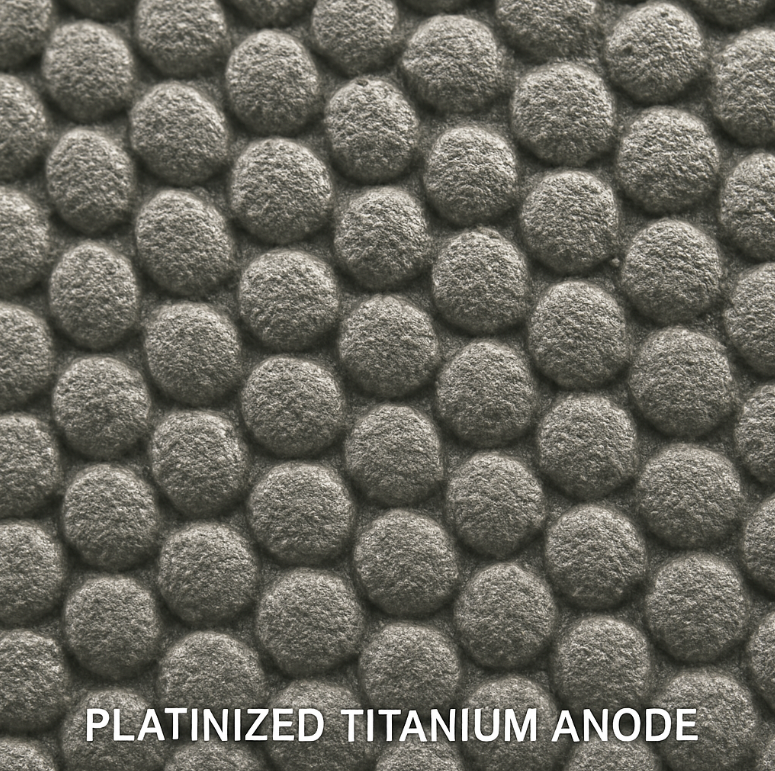

Platinized titanium anodes consist of two parts: a titanium substrate and a thin layer of platinum coating. This combination brings together the advantages of both materials: the strength and corrosion resistance of titanium, and the excellent conductivity and catalytic properties of platinum. This unique combination makes platinized titanium anodes perform exceptionally well in electrochemical processes requiring high efficiency and long life. They can not only effectively transfer current but also resist erosion from harsh environments, ensuring the smooth progress of electrochemical reactions.

Titanium is known for its exceptional strength and lightweight properties. It is widely used in many industries due to its excellent corrosion resistance, especially in environments exposed to corrosive chemicals. This makes titanium an ideal base material for anodes in electrochemical processes. Its natural resistance to corrosion ensures the stability and durability of the anode.

Platinum is a noble metal renowned for its excellent conductivity and oxidation resistance. When used as a coating, platinum significantly enhances the electrical conductivity of the titanium substrate while providing a robust protective layer that can withstand harsh electrochemical conditions. This platinum coating is crucial for ensuring the anode's performance in demanding environments.

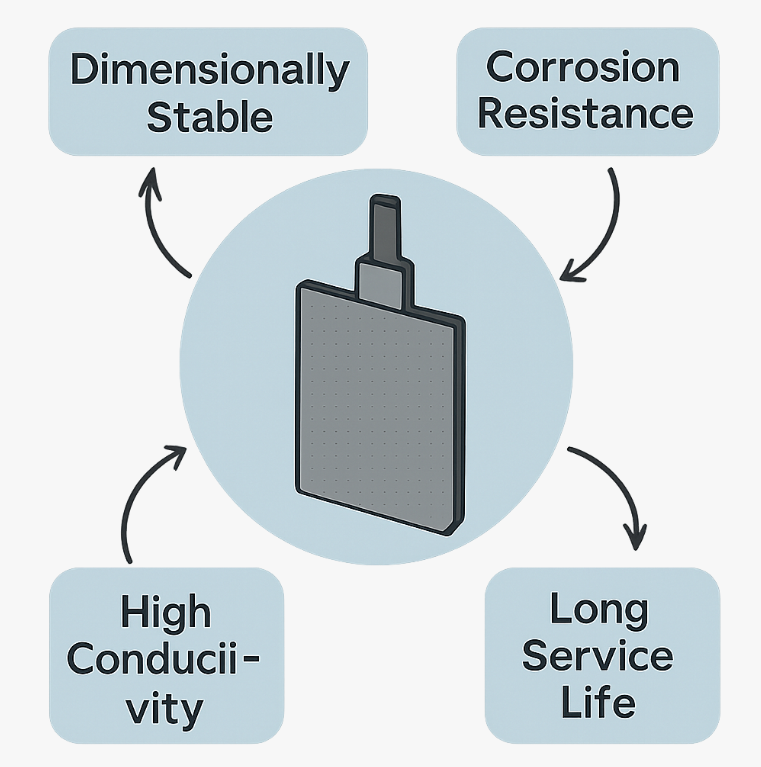

Excellent Corrosion Resistance

One of the most significant advantages of platinized titanium anodes is their excellent corrosion resistance. In electrochemical reactions, anodes are often exposed to highly corrosive environments. The combination of titanium and platinum provides a strong defense against corrosion, ensuring the anode's long service life and continued high efficiency. This corrosion resistant property is key to its outstanding performance in harsh industrial environments.

Superior Conductivity

The platinum coating on titanium anodes significantly enhances their conductivity. This ensures efficient current flow, which is crucial for achieving optimal results in electrochemical processes. High conductivity also leads to reduced energy consumption, resulting in long-term cost savings.

Durable and Long-lasting

Platinized titanium anodes are built to last. The robust nature of titanium, coupled with the protective properties of platinum, ensures that these anodes can withstand the rigors of demanding electrochemical environments. This durability translates to fewer replacements and lower maintenance costs.

Wide Range of Applications

Due to their unique properties, platinized titanium anodes are suitable for a wide range of applications. They are used in industries such as electroplating, water treatment, and chemical production. Their versatility makes them a valuable asset in various electrochemical processes. Especially in areas like titanium plating, their performance is particularly outstanding.

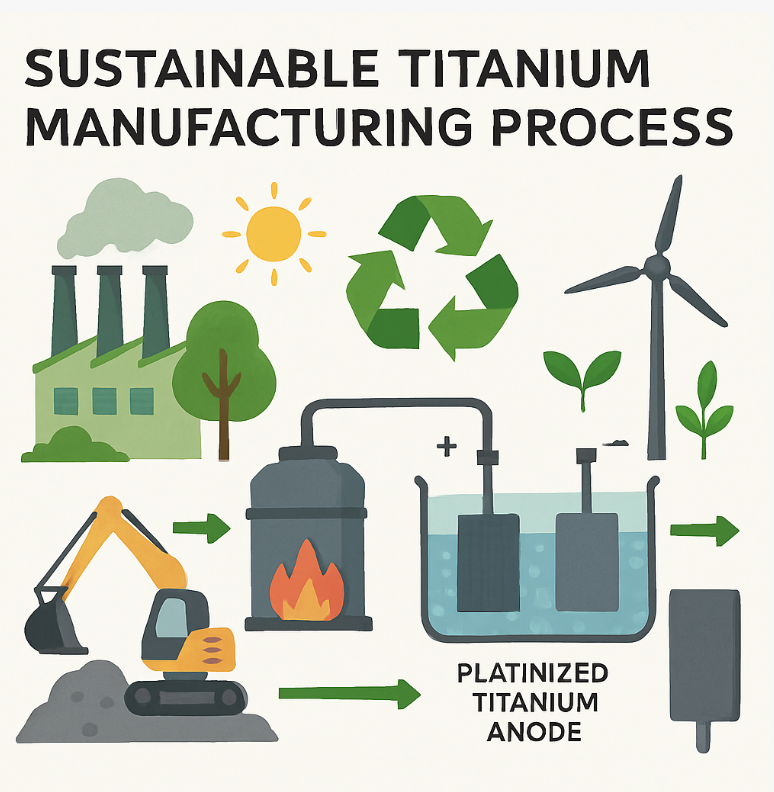

Environmentally Friendly Choice

Using platinized titanium anodes is an environmentally friendly choice. Their long lifespan means fewer replacements and less waste. Additionally, the efficiency they bring to electrochemical processes can lead to reduced energy consumption, further lessening the environmental impact.

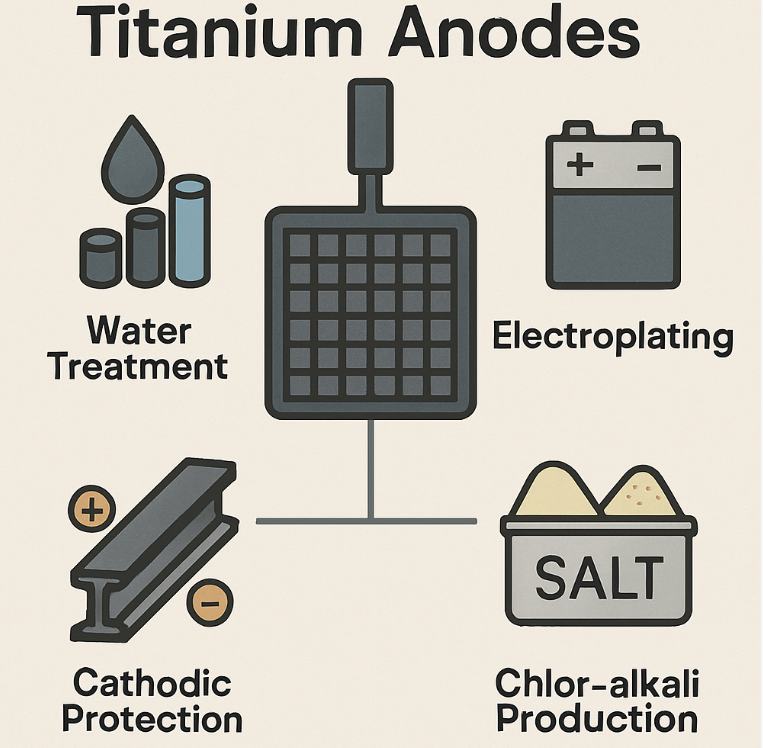

Platinized titanium anodes are widely used in many industries due to their unique advantages. Here are some key application areas:

In the electroplating industry, platinized titanium anodes are favored for their ability to provide a consistent and uniform coating. High conductivity and corrosion resistance ensure that the electroplating process is efficient and produces high-quality finished products. This is very important for manufacturing beautiful and durable products.

In water treatment, these anodes are used in processes such as electrochlorination. They help generate chlorine from saltwater. Due to their durability and corrosion resistance, they are ideal for continuous use in such settings, ensuring water safety.

In the chemical industry, platinized titanium anodes are used to produce various chemicals through electrochemical reactions. Their reliability and efficiency are crucial for maintaining product quality and production consistency. This means more stable production processes and more reliable products.

Choosing the right platinized titanium anode requires considering several factors to ensure optimal performance in specific applications. For expert guidance, contact our specialists who can help you select the perfect solution.

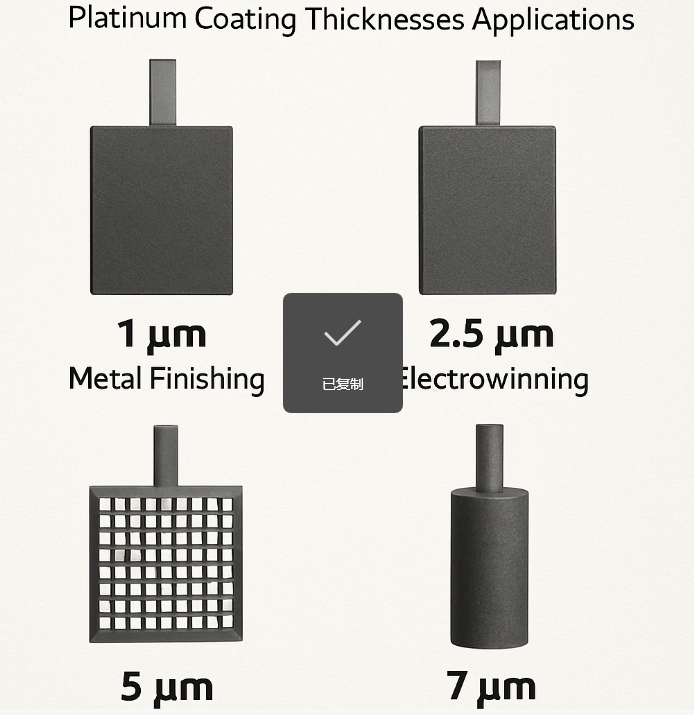

The thickness of the platinum coating can affect the anode's performance and lifespan. Generally, a thicker coating provides better protection and longer life, but it also increases the cost. You need to balance these factors based on your application requirements.

The type of electrolyte used in your process also influences the anode selection. Some electrolytes are more corrosive and may require a more robust anode with a thicker platinum layer to withstand these conditions.

The design of the anode, including its shape and surface area, can affect its efficiency and effectiveness. Customizing the design to suit your specific application can improve performance and yield better results. Our custom fabrication services can help create the perfect anode for your needs.

Platinized titanium anodes offer numerous advantages in the field of electrochemistry, making them an ideal choice. Their excellent corrosion resistance, superior conductivity, and durability make them a reliable and efficient solution for various applications. Whether you are involved in electroplating, water treatment, or chemical production, these anodes can enhance your processes, bringing both environmental and economic benefits.

Incorporating platinized titanium anodes into your electrochemical applications is a wise decision that can significantly improve performance and sustainability. By understanding their advantages and selecting the right anode for your needs, you can optimize your processes and achieve better results.

For more information about our titanium products and custom solutions, or to discuss your specific requirements, please contact us today. Our team of experts is ready to help you find the perfect platinized titanium anode solution for your application.