Getting precise, vibrant colors on titanium can feel like hitting a moving target. Many try various methods, only to find inconsistent results, faded hues, or a finish that simply doesn't hold up. The secret to unlocking a full spectrum of durable colors on titanium isn't magic; it's mastering the science of anodizing, specifically how voltage acts as your control knob.

This guide cuts through the noise, offering clear, actionable insights into how you can consistently achieve stunning, specific colors on titanium through anodizing. We'll explore the science, the setup, and the practical steps to make your titanium projects pop.

Understanding Titanium Anodizing: The Basics

Titanium anodizing isn't just a fancy way to paint metal. It's an electrochemical process that forms a protective, colorful oxide layer directly on the titanium surface. This isn't a coating that can chip or peel; it's an integral part of the metal itself.

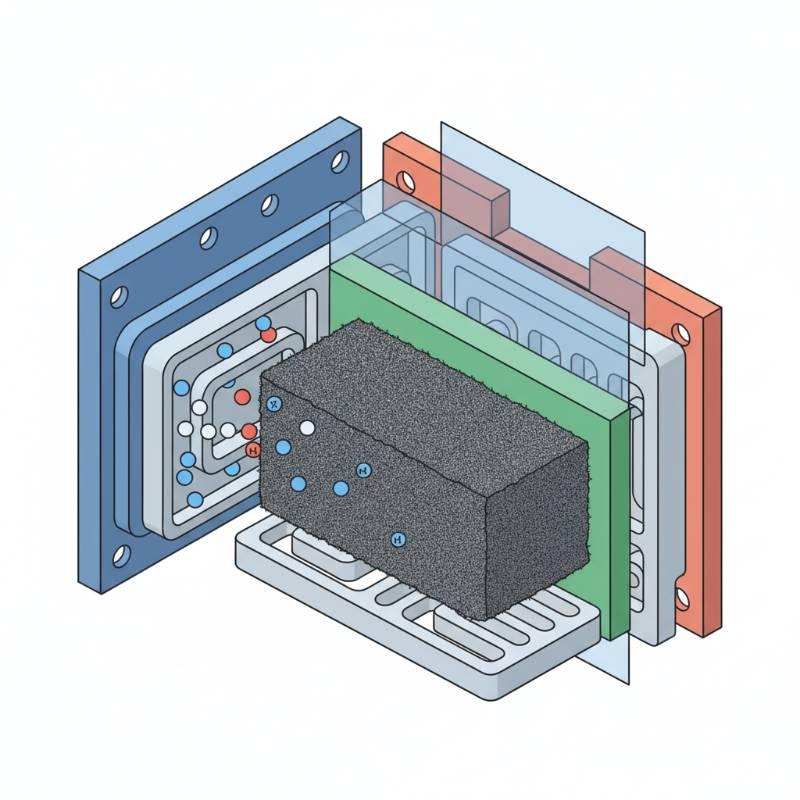

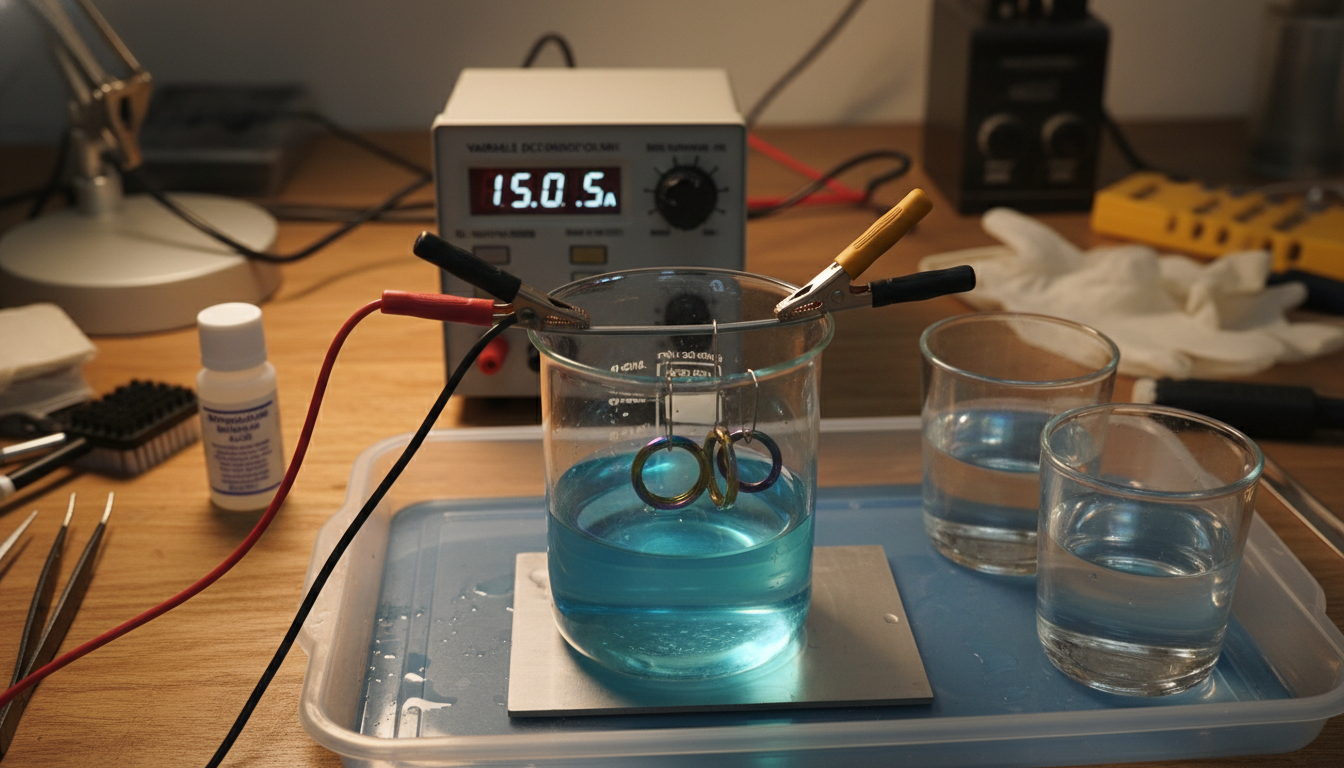

The process is straightforward: immerse a clean titanium piece into an electrolyte solution. Connect it as the anode (positive electrode) and another inert material (like stainless steel or graphite) as the cathode (negative electrode). Apply an electric current. What happens next is pure science at work.

Titanium Anodizing: An electrochemical passivation process that converts the surface of titanium into an anodic oxide layer, allowing for controlled color formation through light interference.

As the current flows, oxygen atoms from the water in the electrolyte combine with the titanium, forming a thin, transparent titanium dioxide (TiO₂) film. The thickness of this film is directly controlled by the applied voltage. This precise control over layer thickness is the whole ball game when it comes to color. For comprehensive titanium manufacturing services, understanding such surface treatments is crucial.

The Science Behind the Spectrum: How Voltage Creates Color

Forget pigments or dyes. The colors you see on anodized titanium are structural colors, a trick of light interference, much like a soap bubble or an oil slick. The transparent titanium oxide layer acts as a prism, reflecting and refracting light. When white light hits this layer, certain wavelengths interfere with each other, either canceling out or reinforcing specific colors.

The key variable here is the thickness of that oxide layer. A thinner layer will reflect different wavelengths than a thicker one. And what controls that thickness? Voltage. Apply more voltage, and the oxide layer grows thicker. This direct relationship means you can dial in your desired color by simply adjusting the power supply.

Different voltages yield distinct colors, progressing through the spectrum as the film thickens. Think of it as a rainbow you can manipulate. This phenomenon is well-documented in materials science, proving the reliability of the method. For instance, research published in materials journals often details the precise optical properties of these films. One study highlights how anodic oxidation parameters directly influence the film's microstructure and resulting colors.

This process offers a level of precision that traditional coloring methods can't touch. It's not about adding color; it's about revealing it from within the material itself.

Essential Equipment and Safety for Titanium Anodizing

Before you jump into coloring, gather your tools and get your safety gear in order. You wouldn't go to battle without your armor, right? Anodizing involves electricity and chemicals, so a little caution goes a long way.

Key Equipment

DC Power Supply (Rectifier): This is your bread and butter. You need a variable DC power supply that can output anywhere from 0 to 120 volts, depending on the colors you want to achieve. Precision is key here.

Electrolyte Solution: Common choices include TSP (trisodium phosphate), household borax, or phosphoric acid. Distilled water is a must for mixing.

Anode (Titanium Piece): The item you want to color. Make sure it's thoroughly cleaned beforehand.

Cathode (Inert Material): Stainless steel sheet or graphite rod.

Container: A non-conductive plastic or glass container to hold the electrolyte.

Leads and Clips: Alligator clips and insulated wires to connect your power supply to the anode and cathode. Use titanium wire for the anode connections to avoid contaminating the bath or creating unwanted reactions.

Cleaning Supplies: Acetone, isopropyl alcohol, or specialized degreasers. A clean surface is non-negotiable for consistent colors.

Getting the right equipment ensures a smooth process. If you're looking for custom titanium components that are ready for anodizing, China Titanium Factory can provide expertly machined parts.

Critical Safety Precautions

Eye Protection: Safety goggles or a face shield are mandatory. Electrolytes can splash.

Gloves: Chemical-resistant gloves protect your hands from the electrolyte.

Ventilation: Work in a well-ventilated area. While most common electrolytes aren't highly noxious, good airflow is always a smart move.

Power Awareness: You're dealing with electricity. Ensure all connections are secure and dry. Never touch the electrodes while power is on. Keep a fire extinguisher nearby, just in case.

First Aid: Know where your first aid kit is. Have a plan for accidental chemical contact.

Safety first, always. Don't cut corners here. You'll thank yourself later.

Achieving Specific Colors: A Practical Voltage-to-Color Guide

This is where the rubber meets the road. Knowing the science is one thing; putting it into practice to get that perfect shade of blue or gold is another. The beauty of anodizing is its predictability. Once you know the voltage-to-color relationship for your specific setup, you can replicate results with high consistency.

The Voltage-to-Color Spectrum

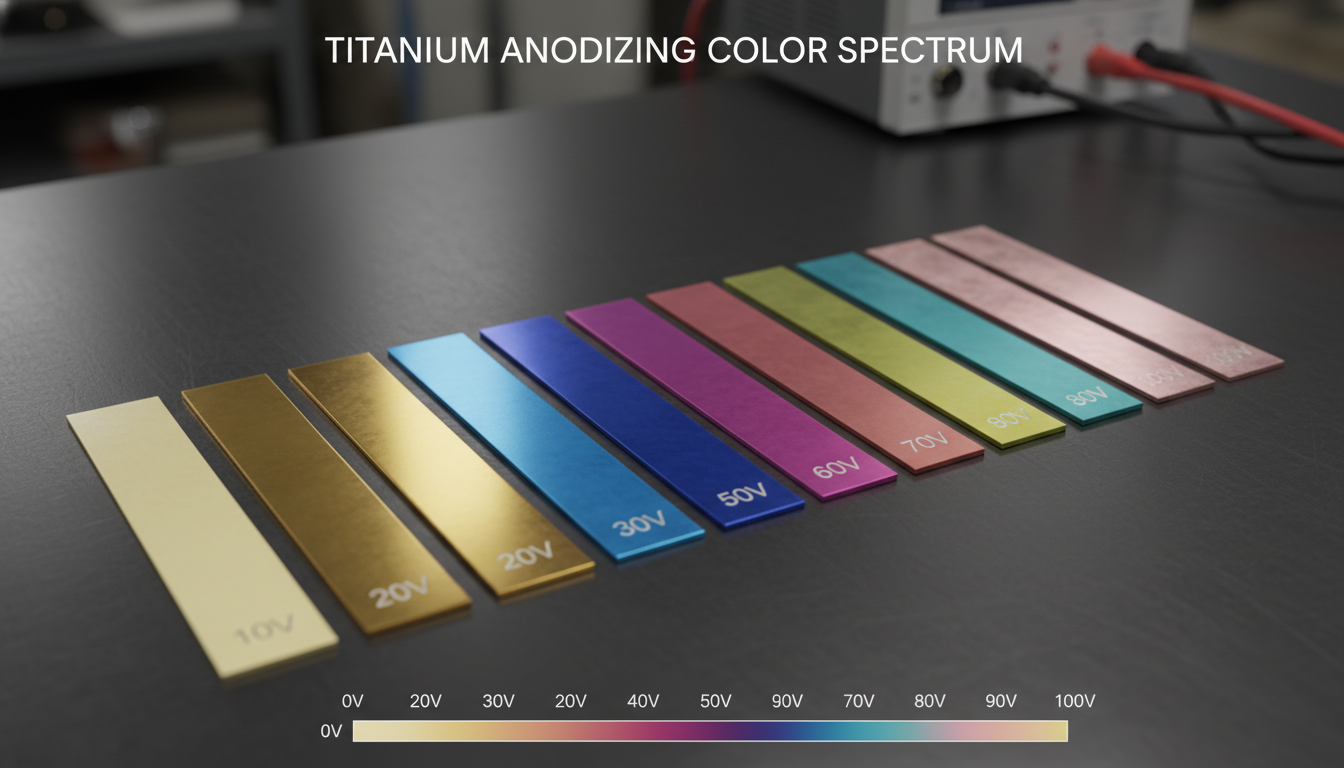

While exact voltages can vary slightly based on electrolyte concentration, titanium alloy, and surface finish, here's a general guide to expected colors:

| Voltage (V) | Approximate Color | Notes |

|---|---|---|

| 10-15 | Light Tan / Bronze | Often the first visible color, subtle. |

| 20-25 | Yellow / Gold | Bright and distinct. |

| 30-35 | Brown / Rose Gold | Warm tones. |

| 40-45 | Purple / Violet | A popular choice, quite striking. |

| 50-55 | Dark Blue / Indigo | Deep and rich. |

| 60-65 | Light Blue / Sky Blue | Vibrant, often seen in jewelry. |

| 70-75 | Teal / Greenish Blue | A transitional color. |

| 80-85 | Green / Chartreuse | Can be tricky to get pure. |

| 90-95 | Pink / Rose | Often a blend or pastel. |

| 100-110 | Light Purple / Magenta | Approaching the end of the first order colors. |

Pro Tip: Always start with a lower voltage and slowly increase it, observing the color change. The color will appear almost instantly once the target voltage is reached. Don't go past the voltage for your desired color, as you can't go backward without stripping the oxide layer.

Consistency is King

To ensure consistent results:

Cleanliness: Absolute paramount. Fingerprints, oils, or residues will show up as dull spots or areas with no color.

Electrolyte Stability: Keep the electrolyte at a consistent concentration and temperature.

Even Immersion: Submerge the titanium piece smoothly and completely.

Calibration: Periodically check your power supply's voltage output against a multimeter.

Think of it like baking. Follow the recipe, and you get a consistent cake. Deviate, and you might get a brick. Or in this case, a blotchy piece of titanium.

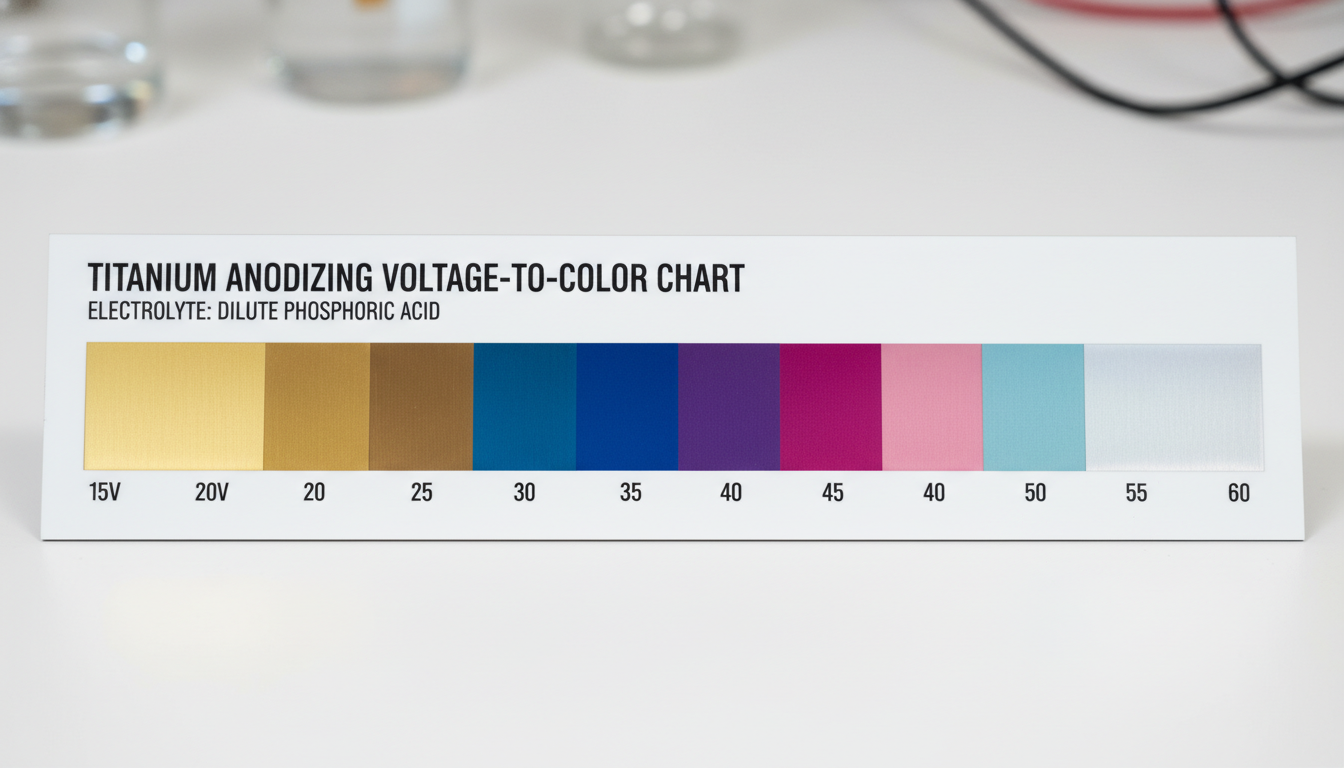

The Role of Electrolytes in Color Formation and Quality

While voltage dictates the oxide layer's thickness, the electrolyte solution acts as the medium, influencing the quality, consistency, and even subtle nuances of the color. It's not just glorified water; it's a critical component.

Common Electrolyte Types

Trisodium Phosphate (TSP): A common household cleaner, TSP is a popular choice for beginners. It's affordable, relatively safe, and produces good results. Colors tend to be vivid.

Borax: Another accessible option, borax (sodium borate) also works well. It's similar to TSP in terms of ease of use and safety profile.

Phosphoric Acid: Often used in more professional setups, phosphoric acid can yield brighter, more consistent colors, especially at higher voltages. However, it requires more stringent safety precautions due to its corrosive nature.

Coca-Cola: Believe it or not, some hobbyists use Coca-Cola due to its phosphoric acid content. Results can be varied and less predictable, but it's a testament to the versatility of the process.

How Electrolytes Influence the Process

The type and concentration of your electrolyte affect several factors:

Conductivity: A more conductive electrolyte allows the current to flow more easily, potentially speeding up the process.

Oxide Layer Quality: Different electrolytes can produce oxide layers with varying densities and microstructures. This can impact the durability and vibrancy of the final color. Phosphoric acid often leads to a denser, more uniform film.

Color Nuances: While the primary color is determined by voltage, the electrolyte can slightly shift the hue or saturation. For example, some electrolytes might produce a "cooler" blue or a "warmer" gold.

Surface Finish: Aggressive electrolytes can sometimes etch the titanium surface, affecting the final aesthetic.

Experimentation is part of the game. Start with a known good recipe (like a dilute TSP solution) and make small adjustments. Keep notes on your electrolyte ratios and the results you get. This helps you dial in your process.

Advanced Titanium Anodizing Techniques for Unique Designs

Once you've got the basics down, you're ready to push the envelope. Titanium anodizing isn't just for single, solid colors. There's a whole world of intricate designs and multi-color effects waiting to be explored.

Multi-Color Anodizing

This technique is a real showstopper. It involves anodizing at multiple voltages to create different colors on the same piece. The trick? You can always increase the voltage to change a color, but you can't decrease it without stripping the existing oxide layer.

Here's the general approach:

Start with your highest desired voltage color. Anodize the entire piece (or the area you want that color).

Clean the piece thoroughly.

Mask off the areas you want to keep at the higher voltage color.

Re-anodize at a lower voltage to achieve a new color on the unmasked areas.

Repeat the masking and re-anodizing process for each subsequent lower voltage color.

It takes patience and a steady hand, but the results are worth the effort. For complex multi-color designs, it might be beneficial to consult with experts in custom titanium design and engineering.

Masking Techniques

Masking is how you create patterns, logos, or defined areas of color. There are several options:

Nail Polish: Cheap, effective, and easy to remove with acetone. Great for small details.

Vinyl Stencils: Laser-cut vinyl masks offer crisp lines and intricate patterns.

Wax: Melted wax can be applied to create organic or textured masks.

Electrical Tape: Good for straight lines or larger blocked-off areas.

Ensure your mask adheres completely and has no gaps where the electrolyte can seep underneath. A leaky mask is a heartbreaker.

Gradient Anodizing

Want a smooth transition from one color to another? Gradient anodizing is your ticket. This involves slowly immersing or withdrawing the titanium piece from the electrolyte while the current is applied. The areas submerged for longer or exposed to higher voltages will develop thicker oxide layers and thus different colors.

It's an art form. Practice on scrap pieces to get a feel for the speed of immersion/withdrawal and how it affects the color blend. The beauty of gradients lies in their organic, flowing appearance.

Troubleshooting Common Titanium Anodizing Problems

Even the pros hit a snag now and then. Don't throw in the towel if your first few attempts aren't perfect. Most problems have straightforward solutions. Here's a rundown of common issues and how to fix them.

Uneven Color or Streaks

The Problem: Patches of different colors, streaks, or faded areas.

The Fix:

Poor Cleaning: This is the number one culprit. Re-strip the existing oxide layer (see below) and re-clean meticulously with acetone or isopropyl alcohol, followed by a distilled water rinse. Consider an ultrasonic cleaner for intricate pieces.

Inconsistent Immersion: Ensure the piece is fully and smoothly immersed. Don't hesitate or pull it out halfway.

Poor Electrical Contact: Check your titanium wire and alligator clip connections. A loose connection means uneven current flow.

Weak Electrolyte: If your solution is old or too dilute, it might struggle to conduct evenly. Replace or strengthen it.

No Color Formation

The Problem: You apply voltage, but nothing happens. The titanium remains its original dull gray.

The Fix:

No Current Flow: Double-check all your connections. Is the power supply on? Is the voltage set correctly? Are the anode and cathode both properly submerged?

Contaminated Titanium: Sometimes titanium can have a passive layer from machining or prior handling. A quick dip in a mild acid (like a dilute hydrofluoric acid solution, with extreme caution and proper PPE) can sometimes reactivate the surface, but this is for advanced users only. Mechanical abrasion (sanding) can also help.

Incorrect Electrolyte: Ensure you're using a conductive electrolyte, not just pure water.

Pitting or Rough Surface

The Problem: The anodized surface looks rough, pitted, or has a dull, grainy texture.

The Fix:

Overly Aggressive Electrolyte: Your electrolyte might be too strong or too acidic. Try diluting it or switching to a milder option like TSP.

Impure Titanium: While rare, impurities in the titanium itself can sometimes lead to uneven etching during anodizing. This is usually beyond your control.

High Current Density: Too much current in a small area can cause localized etching. Ensure your cathode is large enough and positioned correctly.

Inconsistent Results Between Batches

The Problem: You got a perfect blue yesterday, but today it's purple at the same voltage.

The Fix:

Electrolyte Degradation: Electrolytes can degrade over time or become contaminated. Replace it with a fresh batch.

Temperature Fluctuations: The temperature of your electrolyte can affect conductivity and reaction rates. Aim for a consistent room temperature.

Surface Finish Variation: Even subtle differences in the initial polish or finish of the titanium can affect the final color. Maintain consistent prep.

Stripping and Re-Anodizing

Messed up a piece? No sweat. You can usually strip the oxide layer and try again. For most titanium alloys, a quick dip in a common rust remover containing phosphoric acid (like Naval Jelly, used cautiously) or even strong household cleaners can remove the oxide layer. Rinse thoroughly and re-clean before re-anodizing. This is a big advantage over other coloring methods.

Applications of Colored Titanium: From Jewelry to Aerospace

The ability to precisely color titanium isn't just a novelty; it's a powerful tool with applications spanning a multitude of industries. Its unique blend of aesthetic appeal and inherent functional benefits makes it a standout material.

Jewelry and Artistic Creations

This is perhaps the most obvious application. Jewelers love anodized titanium for its vibrant, non-fading colors and hypoallergenic properties. Earrings, pendants, rings, and artistic sculptures gain a distinct, modern edge with these rich hues. The lightweight nature of titanium also makes it comfortable to wear.

Medical and Dental Implants

Here, color serves a functional purpose. Anodizing isn't just about aesthetics; it also enhances biocompatibility and corrosion resistance. Different colors can be used for identification purposes during surgery or for differentiating between various implant sizes and types. This level of precision is critical in medical fields. Studies confirm the excellent biocompatibility of anodized titanium surfaces.

Aerospace and Automotive

In these demanding sectors, every ounce counts, and performance is king. Anodizing not only provides visual differentiation for components but also boosts corrosion resistance without adding significant weight or affecting the material's strength. Think about color-coded fasteners, brackets, or decorative interior trim that withstand harsh environments. For top-tier titanium products, precise surface finishes are often a requirement.

Consumer Electronics and Sporting Goods

From smartphone casings and laptop bodies to high-performance bicycle frames and golf club heads, anodized titanium brings a premium look and feel. Its light weight, strength, and scratch resistance, combined with customizable colors, make it a natural fit for products where aesthetics and durability go hand-in-hand.

Architectural and Decorative Elements

The ability to create large-scale colored titanium panels opens doors for architects and designers. Imagine facades, interior accents, or artistic installations that shimmer with iridescence, changing hues with the light. It's a striking way to use a high-performance material.

The versatility of anodized titanium ensures its continued presence across diverse markets, proving that beauty and function can indeed coexist.

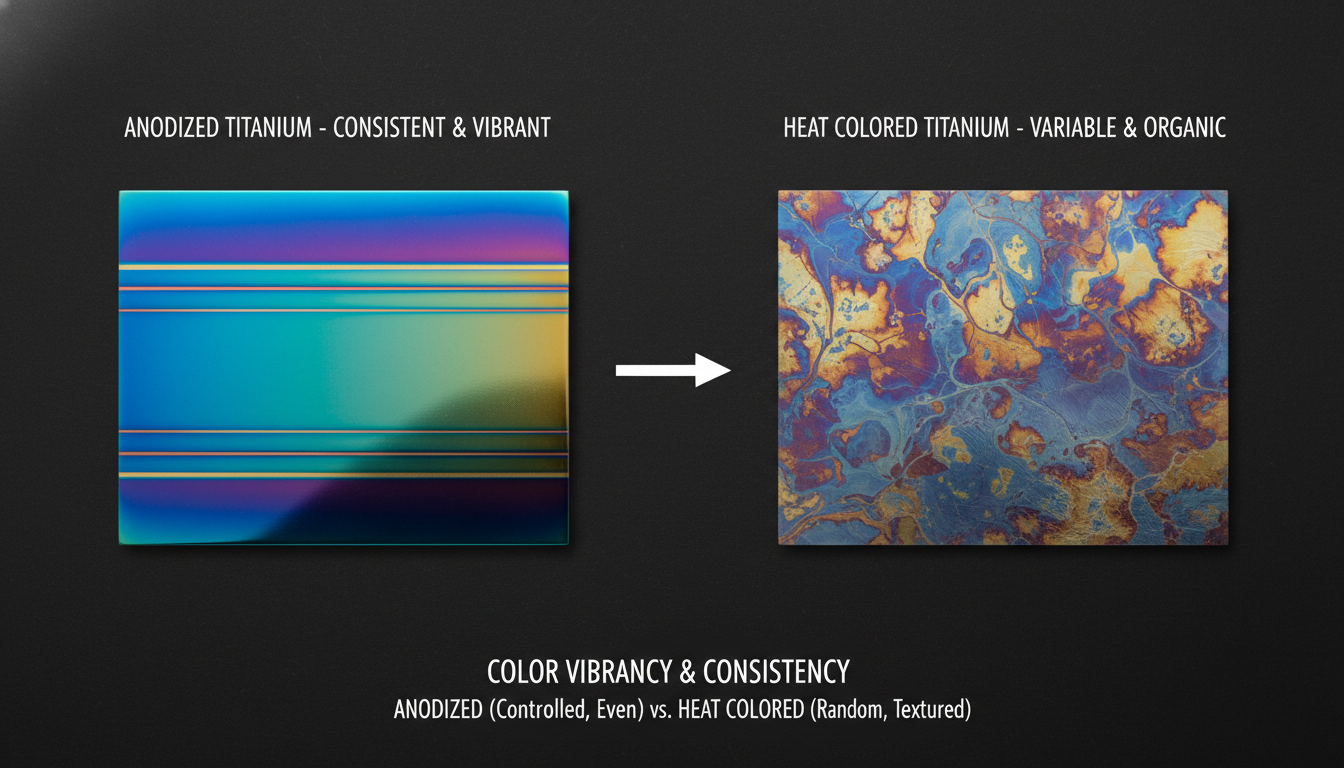

Titanium Anodizing vs. Heat Coloring: A Detailed Comparison

Before diving headfirst into anodizing, it's worth understanding the other primary method for coloring titanium: heat coloring. Both techniques can produce vibrant colors, but they rely on different principles and come with their own sets of pros and cons.

Heat Coloring Titanium

Heat coloring involves exposing titanium to specific temperatures, causing an oxide layer to form naturally as it reacts with oxygen in the air. As the temperature increases, the oxide layer thickens, leading to a progression of colors similar to anodizing.

Pros: No chemicals, simple setup (torch or oven), can create interesting gradients.

Cons: Less precise color control, colors can be less vibrant and more muted, less durable than anodized finishes, and harder to replicate consistently. The heat can also affect the underlying metal's temper or hardness, especially for thin sections or precision components.

Anodizing Advantages

Anodizing generally holds the upper hand for controlled, durable coloring.

Precision: Voltage offers far more granular control over color than temperature. You can dial in exact hues.

Vibrancy & Consistency: Anodized colors are typically brighter, more consistent, and less prone to variations across a piece.

Durability: The electrically formed oxide layer tends to be denser and more uniform, offering superior scratch and wear resistance compared to a heat-formed layer. This is crucial for applications requiring longevity.

No Heat Distortion: Since it's a cold process, anodizing doesn't introduce heat that could warp or alter the mechanical properties of the titanium. This is a big deal for precision parts.

Reproducibility: Once you establish a voltage-to-color chart for your setup, you can reliably reproduce colors batch after batch.

While heat coloring has its place for rustic or artistic effects where precision isn't paramount, for most industrial or high-quality aesthetic applications, anodizing is the clear winner. A deeper dive into the mechanical properties of thermally grown oxide layers further illustrates these differences. Research on oxide growth kinetics often points to the superior control offered by electrochemical methods.

Limitations of Anodizing

No process is without its drawbacks. Anodizing cannot produce true red or black. The interference colors are limited to the spectrum produced by the oxide layer's refractive properties. While you can get pinks and deep purples, a pure, fire-engine red isn't achievable. Black is also not possible through this method; titanium will remain its natural gray if not anodized or will show a very dark brown at very low voltages.

Scaling Your Anodizing Operations: Equipment Recommendations

Whether you're dipping your toe in the water or looking to go pro, the right equipment makes all the difference. Your setup should match your ambition and production volume. Don't buy a tanker when all you need is a dinghy.

Hobbyist or Small Workshop Setup

For personal projects, jewelry making, or small-batch runs, keep it simple and cost-effective.

Power Supply: A variable DC power supply (0-120V, 1-5A) is sufficient. Benchtop lab power supplies work great.

Containers: Food-grade plastic containers or glass beakers.

Electrolyte: Easily sourced household TSP or borax.

Cathode: A piece of stainless steel scrap or a graphite rod.

Connections: Standard alligator clips and insulated wire.

This setup is perfect for learning the ropes without breaking the bank. It's forgiving and easy to manage.

Medium-Scale Production or Professional Studio

Stepping up your game means investing in more robust and efficient gear.

Power Supply: A dedicated anodizing rectifier with higher amperage (e.g., 10-20A) for faster processing of larger or multiple pieces. Look for programmable voltage and current limiting.

Tanks: Larger, dedicated polypropylene or PVC tanks for electrolyte, often with heating/cooling capabilities to maintain consistent temperature.

Electrolyte: Phosphoric acid solutions are often preferred for their consistency and brighter colors at scale.

Agitation: Magnetic stirrers or air bubblers to ensure uniform electrolyte concentration and prevent localized depletion.

Rinsing Stations: Dedicated rinse tanks with distilled water to prevent cross-contamination.

Ventilation: A proper fume hood system, especially when using more aggressive electrolytes.

This level of equipment allows for higher throughput and more consistent quality. When considering scaling up, understanding your material needs and processing capabilities is vital. China Titanium Factory has extensive experience in managing large-scale titanium projects and can offer insights into industrial requirements.

Industrial Scale Operations

At the industrial level, it's about automation, volume, and rigorous process control.

Automated Rectifiers: Computer-controlled systems with precise voltage and current ramping profiles.

Automated Hoists and Tank Lines: Conveyor systems move parts through pre-treatment, anodizing, and post-treatment baths.

Filtration and Recirculation: Advanced filtration systems to maintain electrolyte purity and extend its life.

Waste Treatment: Comprehensive systems for managing and neutralizing spent chemicals.

Quality Control: Inline spectrophotometers and other instruments for real-time color and thickness measurement.

Industrial anodizing is a highly specialized field, often integrated into a larger manufacturing process. It requires significant capital investment and expertise to operate efficiently.

Frequently Asked Questions About Titanium Anodizing

Is titanium anodizing safe?

Yes, when proper safety precautions are followed. You're working with electricity and mild chemicals. Always wear appropriate personal protective equipment (PPE) like gloves and eye protection. Ensure good ventilation. Avoid contact with the live electrical current. Common household electrolytes like TSP are generally low-risk, but stronger acids require more careful handling.

How long do anodized colors last?

Anodized titanium colors are very durable because they're part of the metal's surface, not a coating. They won't chip or peel. However, they can fade over time with prolonged exposure to harsh UV light, abrasion, or certain chemicals. With proper care, they can last for many years, even decades, depending on the application and environment.

Can I re-anodize titanium if I don't like the color?

Absolutely. One of the great advantages of titanium anodizing is its reversibility. You can strip the existing oxide layer using specialized chemicals (like certain rust removers or mild acids) or by simply sanding it off. Once the surface is clean and free of the old oxide, you can re-anodize it to a new color.

Does anodizing affect titanium's strength or properties?

For the thin oxide layers produced during decorative anodizing, the effect on titanium's mechanical strength is negligible. The process is "cold," meaning it doesn't involve the high temperatures that could alter the metal's temper. In fact, the oxide layer enhances corrosion resistance and biocompatibility, which are beneficial properties.

What type of titanium can be anodized?

Most commercially pure (CP) titanium grades (Grades 1-4) and some titanium alloys (like Ti-6Al-4V, Grade 5) can be successfully anodized. CP grades generally produce more vibrant and consistent colors. Alloys might yield slightly different hues or require specific voltage adjustments due to their varied compositions, but the principle remains the same.

Ready to Bring Your Titanium Visions to Life?

Mastering titanium anodizing opens a world of possibilities for custom aesthetics and enhanced functionality. Whether you're a hobbyist or a professional, understanding voltage control is your key to unlocking stunning results.

Need high-quality titanium raw materials, custom machined parts, or expert guidance on advanced titanium applications? Contact China Titanium Factory today. Our team is equipped to support your projects, from concept to vibrant completion. Let's create something extraordinary together.