Titanium is renowned for its high strength, low density, and outstanding corrosion resistance. These characteristics make it particularly valuable in sectors where performance and reliability are paramount. In addition to these primary attributes, titanium is also biocompatible, making it suitable for medical implants and devices. Its non-magnetic nature further expands its utility in electronics and other specialized applications. Common applications include:

Aerospace: Used in airframes, engine components, and landing gear due to its ability to withstand extreme temperatures and conditions. The metal's lightweight nature contributes to fuel efficiency, a critical factor in modern aviation.

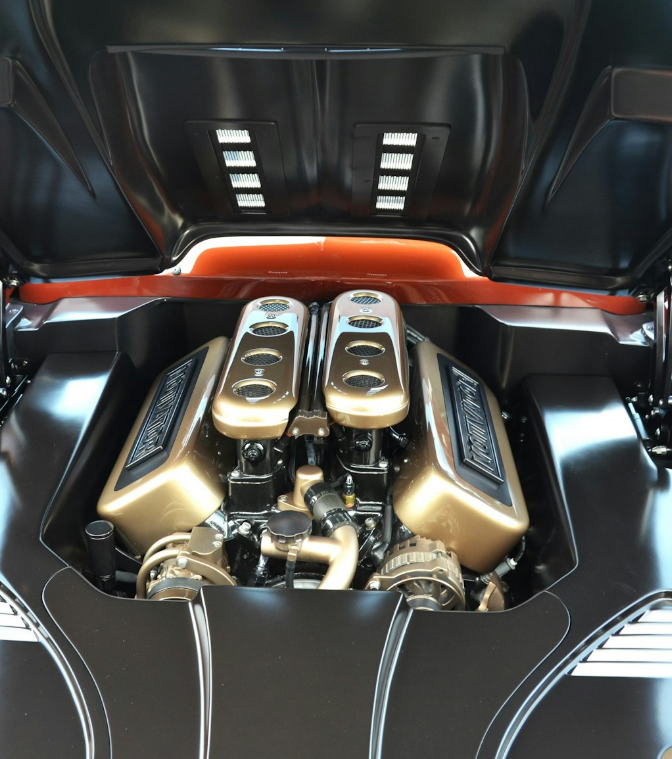

Automotive: Often chosen for exhaust systems and performance parts, titanium reduces weight while enhancing durability. It also contributes to improved vehicle handling and acceleration, key factors in high-performance automotive engineering.

Chemical Processing: Its corrosion resistance makes titanium an ideal choice for pipes and tanks in chemical plants. This resistance guarantees that the material can withstand highly reactive substances without deteriorating, thereby protecting both the environment and the investment.

Marine: Used in shipbuilding and offshore drilling due to its resistance to seawater corrosion. This makes it an ideal option for components regularly exposed to harsh marine conditions, ensuring durability and lower maintenance costs.

Titanium comes in various grades, each with distinct properties. The choice of grade impacts the titanium pipe price and its suitability for specific applications. Understanding the nuances of each grade can significantly influence the performance and cost-effectiveness of your project.

Grade 1: Offers excellent corrosion resistance but lower strength, ideal for applications requiring superior ductility. It's often used in applications where forming and welding are crucial, thanks to its high malleability.

Grade 2: Known for its balance of strength and ductility, commonly used in the chemical and marine industries. This grade is often chosen when a good compromise between formability and strength is needed without a significant cost increase.

Grade 5 (Ti-6Al-4V): The most widely used titanium alloy, offering high strength and good corrosion resistance, making it suitable for aerospace and automotive applications. Its use is prevalent in critical components where failure is not an option.

Grade 9: Known for its high strength and formability, often used in aircraft titanium tubing and sports equipment. This grade is particularly valued for its weldability and ability to withstand high-stress environments.

The sizing of titanium pipes is crucial to their performance and integration into existing systems. Proper sizing ensures that the pipes not only fit but also function optimally under the expected conditions.

Diameter and Wall Thickness: Determine the internal pressure the pipe must withstand and select a size that provides the necessary strength without excessive weight. Accurate measurement and calculations are essential to avoid over-engineering and unnecessary costs.

Length: Ensure the pipe length aligns with your project requirements to minimize waste and reduce costs. Custom lengths may also be an option, providing flexibility in design and application.

Working with a reputable titanium tube distributor is essential to ensure quality and consistency. A reliable supplier not only delivers high-quality materials but also provides technical support and logistical solutions.

Certifications and Standards: Verify that the supplier adheres to industry standards such as ASTM and ASME, ensuring the materials meet required specifications. These certifications are a testament to the supplier's commitment to quality and compliance.

Traceability: Ensure the supplier provides full traceability of the materials, from raw material sourcing to the final product, to maintain quality assurance. This transparency is crucial for accountability and problem resolution.

Customer Service: A supplier with excellent customer service can provide valuable support in selecting the right products and addressing any issues that may arise. Effective communication with the supplier can streamline procurement and resolve potential challenges efficiently.

The titanium pipe price can vary significantly based on factors such as grade, size, and market conditions. Being informed about these factors can help you plan your budget more accurately and avoid unexpected costs.

Bulk Purchases: Buying in larger quantities can often reduce the per-unit cost, making it a more economical choice for large projects. Negotiating with suppliers for bulk discounts can result in substantial savings.

Market Trends: Stay informed about market trends and fluctuations in titanium tube prices to make informed purchasing decisions. This awareness can help in timing purchases to take advantage of favorable market conditions.

In the aerospace sector, precision and reliability are non-negotiable. A leading aerospace manufacturer faced challenges in sourcing high-quality titanium tubing for their aircraft components. By partnering with a specialized titanium pipe supplier, they secured a consistent supply of Grade 5 titanium, ensuring their components met stringent industry standards and were delivered on time, enhancing their production efficiency and product safety. This strategic partnership allowed them to focus on innovation without compromising on material quality or availability.

A performance car manufacturer sought to improve their vehicle's efficiency by reducing weight without compromising strength. They opted for a titanium exhaust pipe, leveraging its lightweight and high-strength properties. By working closely with a titanium tubing supplier, they developed a custom solution that improved vehicle performance and fuel efficiency. This collaboration not only resulted in a more competitive product but also provided valuable insights into material utilization and design optimization.

A chemical processing plant required corrosion-resistant piping to handle aggressive chemicals. By selecting Grade 2 titanium pipes, they ensured long-term reliability and reduced maintenance costs, optimizing their operational efficiency. The decision to use titanium also minimized downtime due to its longevity and resistance to chemical wear, ultimately contributing to a safer and more sustainable operation.

In industries where precision and safety are paramount, maintaining consistent quality and adherence to industry standards is critical. Implementing a robust quality assurance program can mitigate risks and enhance operational excellence.

Implement Rigorous Quality Control: Establish a comprehensive quality control program that includes regular inspections and testing to ensure materials meet specifications. This proactive approach helps identify potential issues before they escalate into costly problems.

Work with Certified Suppliers: Collaborate with suppliers that are certified and have a proven track record of delivering high-quality titanium products. Checking sellers helps make sure you work with good ones.

Stay Updated on Industry Standards: Continuously monitor changes in industry standards and regulations to ensure your products remain compliant. Keeping abreast of these developments is critical for maintaining competitive advantage and regulatory compliance.

Choosing the right titanium pipe involves a thorough understanding of the material properties, application requirements, and supplier capabilities. By carefully considering these factors and collaborating with trusted suppliers, you can ensure the success of your projects while optimizing costs and maintaining quality. Whether you are an aerospace engineer, a supply chain manager, or a manufacturing quality control specialist, the right titanium tubing can make a significant difference in the performance and reliability of your products. Embrace the strength and versatility of titanium, and let it propel your projects to new heights of excellence. With the right knowledge and partnerships, titanium can be the cornerstone of innovation and efficiency in your industry.