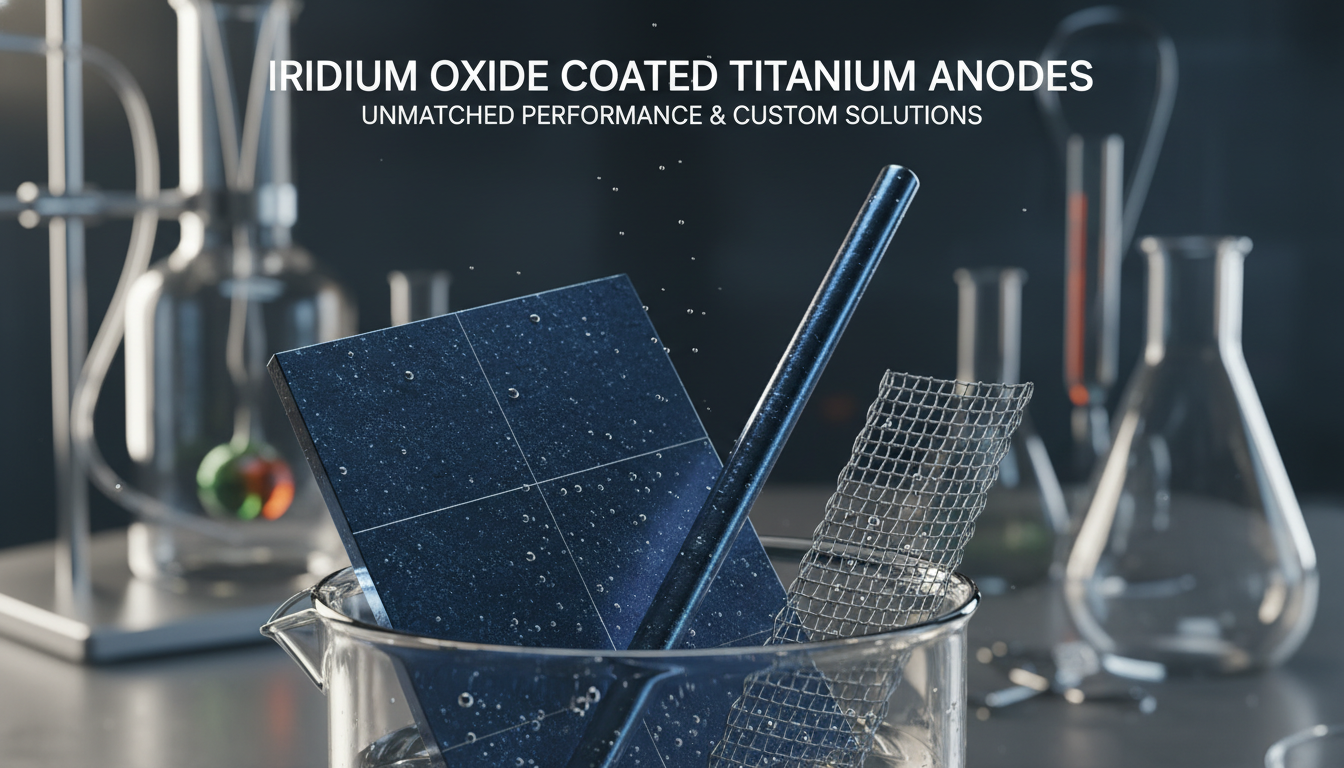

We are a leading manufacturer of Iridium Oxide Coated Titanium Anodes, dedicated to providing exceptional performance and lasting durability for your industrial electrolysis projects. Our DSA (Dimensionally Stable Anodes) are designed for harsh industrial environments, featuring excellent electrochemical efficiency and an extended service life.

Request a Quote

Iridium-Tantalum Coated Titanium Anodes (Ir-Ta Coated Titanium Anodes) are recognized as one of the best electrodes in the field of Oxygen Evolution Reaction (OER). Their active coating, primarily composed of iridium and tantalum oxides, exhibits superior performance in highly corrosive media and under high current densities.

Features an extremely low oxygen evolution potential in acidic electrolytes, significantly reducing cell voltage, thereby saving energy and improving electrolysis efficiency.

Exhibits excellent stability in highly corrosive electrolytes like strong acids (e.g., sulfuric acid), resisting passivation or dissolution, ensuring a long anode lifespan.

Using titanium as the substrate, the anode maintains a stable geometric shape, avoiding the shape changes and electrolyte contamination issues associated with traditional graphite or lead anodes during electrolysis.

Capable of withstanding extremely high operating current densities, suitable for high-yield, high-efficiency industrial electrolysis processes.

| Coating Type | Primary Active Reaction | Typical Application Fields |

|---|---|---|

| Ir-Ta Mixed Oxide | Oxygen Evolution Reaction (OER) | Copper Sulfate Electrolysis, Water Electrolysis for Hydrogen Production, PCB Copper Foil Production, Electroplating, Hydrometallurgy |

| Ir-Ru Mixed Oxide | Chlorine Evolution Reaction (CER) | Chlor-Alkali Industry, Seawater Electrolysis, Sodium Hypochlorite Generators |

| IrO₂ Single Component Coating | High-Selectivity Electrochemical Oxidation | Wastewater Treatment, Organic Electrosynthesis, Electroplating Solution Recovery |

Substrate Material: Commercially Pure Titanium (Gr1, Gr2)

Common Shapes: Mesh, Plate, Tube, Rod, Basket, Wire, Custom Irregular Structures.

Coating Process: Thermal Decomposition Method (High-Temperature Sintering), ensuring uniform and firmly bonded coating.

Customization Service: Precision customization based on customer-provided design drawings and detailed parameters (current density, electrolyte composition, operating temperature, etc.).

Used for the electrolytic extraction and refining of non-ferrous metals such as copper, zinc, and nickel, performing exceptionally well in sulfuric acid systems.

Provides stable and efficient anodic reactions in Printed Circuit Board (PCB) manufacturing and electrolytic copper foil production, ensuring product quality.

Electrochemical oxidation of refractory organic pollutants, achieving COD reduction and disinfection with high efficiency and no secondary pollution.

Serves as the oxygen evolution electrode in PEM electrolyzers, a critical core material for efficient and clean hydrogen production technology.

Used in electroplating processes like chrome and nickel plating, replacing traditional lead anodes to improve bath purity and plating quality.

Acts as a key electrode in the electrosynthesis of organic compounds and the Chlor-Alkali industry, enabling highly efficient electrochemical conversion.

Contact our expert team for customized solutions and technical support. We are committed to helping your electrochemical projects succeed with the most competitive prices and exceptional quality.

Inquire for a Quote Now