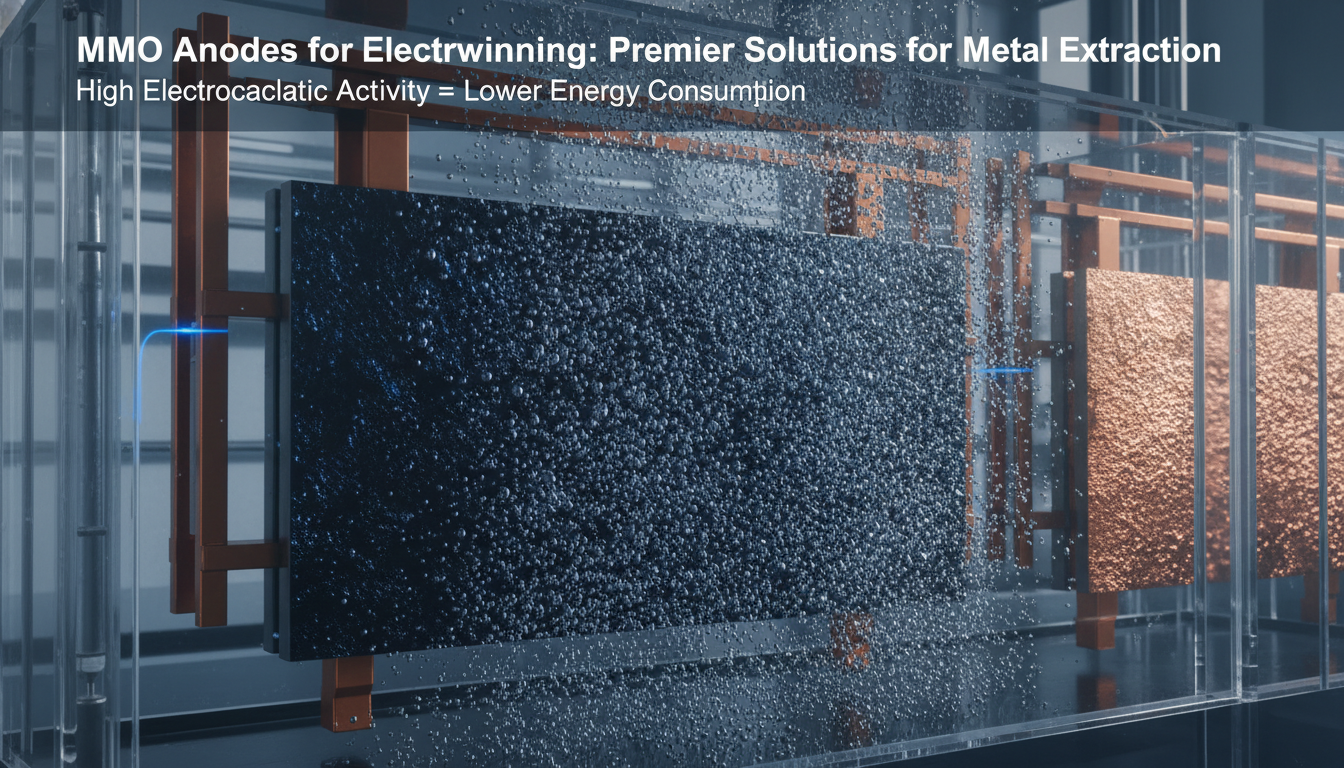

Mixed Metal Oxide (MMO) Anodes are advanced titanium-based electrodes designed for efficient metal extraction of copper, zinc, nickel, and gold. Their superior durability and electrocatalytic performance ensure high purity and energy efficiency.

Request a Quote

Electrowinning is an electrolytic process that deposits high-purity metals on a cathode by applying an external electrical current. MMO anodes, consisting of a titanium substrate coated with mixed metal oxides like ruthenium, iridium, or platinum, facilitate this process by enabling efficient oxygen evolution and metal deposition. These anodes outperform traditional lead dioxide anodes due to their lower energy consumption and cleaner operation.

High Efficiency: Low overpotential reduces energy consumption, enhancing cost-effectiveness in electrowinning processes.

Long Lifespan: Durable coatings ensure service life exceeding 5 years in harsh electrowinning environments.

Corrosion Resistance: Titanium substrate withstands acidic and chloride-rich electrolytes common in electrowinning.

Environmental Benefits: Cleaner alternative to lead anodes, minimizing toxic waste in electrowinning operations.

We tailor the anode's shape and coating composition to the specific metal and electrolyte used in the electrowinning process.

| Configuration | Coating Type | Typical Metal Recovery |

|---|---|---|

| Plate Anodes | Ir-Ta or Ru-Ir Oxide | Copper, Zinc, Nickel, Cobalt. |

| Mesh Anodes | Ir-Ta Oxide | Precious metals (Gold, Silver), specialized recovery. |

| Rod/Tube Anodes | Pt or Ir-Ta Oxide | High-purity metal refining, specialized cells. |

Copper Electrowinning: Ensures uniform deposition and high purity in copper production.

Zinc Recovery: Replaces lead anodes for energy-efficient zinc extraction.

Nickel and Cobalt Electrowinning: Supports high current densities in chloride-rich environments.

Precious Metal Recovery: Facilitates precise extraction of gold and silver.

Contact our electrochemistry experts for a consultation on the optimal anode design and coating for your specific electrowinning application.

Inquire for a Quote Now