We specialize in high-performance components for Proton Exchange Membrane (PEM) Electrolyzers, including advanced Titanium Anodes and Porous Transport Layers (PTLs), essential for efficient and sustainable green hydrogen production.

Request a Quote

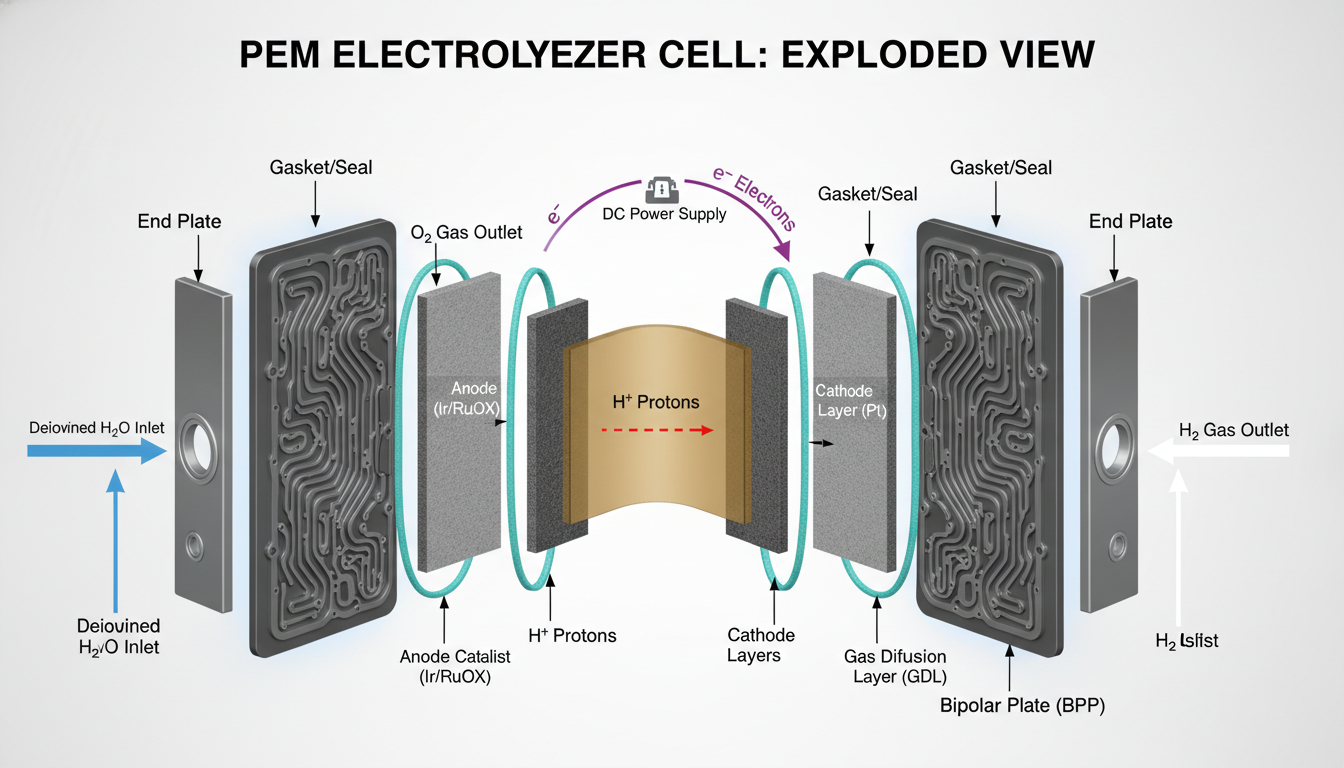

The PEM electrolyzer is a cutting-edge technology for producing high-purity hydrogen by splitting water using electricity. It is characterized by a solid polymer electrolyte (the PEM) that conducts protons, offering high current density, compact design, and rapid response to dynamic power sources like wind and solar. This makes it a key enabler for the green hydrogen economy.

Proton Exchange Membrane (PEM): Separates the anode and cathode compartments while transporting protons (H+).

Catalyst Layers: Typically Iridium/Ruthenium on the anode (Oxygen Evolution Reaction) and Platinum on the cathode (Hydrogen Evolution Reaction).

Titanium Anode (Current Collector): Collects current from the anode side and distributes reactants. Must be highly corrosion-resistant.

Porous Transport Layer (PTL): Facilitates the transport of water, gas, and electrons between the catalyst layer and the bipolar plate.

Our titanium components withstand the highly acidic and oxidative environment at the anode side, ensuring long-term cell integrity.

The components are designed to handle the high current densities characteristic of PEM technology, maximizing hydrogen output.

Optimized surface structures and material purity minimize contact resistance and overpotential, leading to lower energy consumption.

We offer custom Porous Transport Layers (PTLs) in titanium felt or mesh to optimize water and gas management within the cell.

We focus on the critical titanium-based components that ensure the durability and performance of the PEM stack.

| Component | Material/Coating | Function |

|---|---|---|

| Titanium Anode Plate | Pure Titanium (Gr. 1 or 2) | Current collection and distribution on the anode side. |

| Titanium PTL (Porous Transport Layer) | Titanium Felt or Mesh | Gas/water transport and electrical contact between the anode plate and catalyst layer. |

| Titanium Bipolar Plates | Pure Titanium (Gr. 1 or 2) with Gold/Carbon Coating | Separates individual cells and manages fluid flow. |

Compact PEM Electrolyzer: Ideal for small-scale, on-site hydrogen generation (0.01-1 Nm³/h).

Skid-Mounted PEM Generator: Modular systems for industrial applications (1-10 Nm³/h).

Large-Scale Containerized Systems: High-capacity solutions for power-to-gas and large industrial users (50-200 Nm³/h).

Green Hydrogen Production: Coupling with renewable energy sources (solar, wind) for sustainable hydrogen generation.

Energy Storage: Converting surplus renewable electricity into storable hydrogen (Power-to-Gas).

Mobility: Supplying high-purity hydrogen for Fuel Cell Electric Vehicles (FCEVs).

Industrial Feedstock: Providing hydrogen for ammonia synthesis, refining, and chemical manufacturing.

Contact our hydrogen technology experts for consultation on custom titanium components and PTLs to optimize the performance and longevity of your PEM electrolyzer stack.

Inquire for a Quote Now