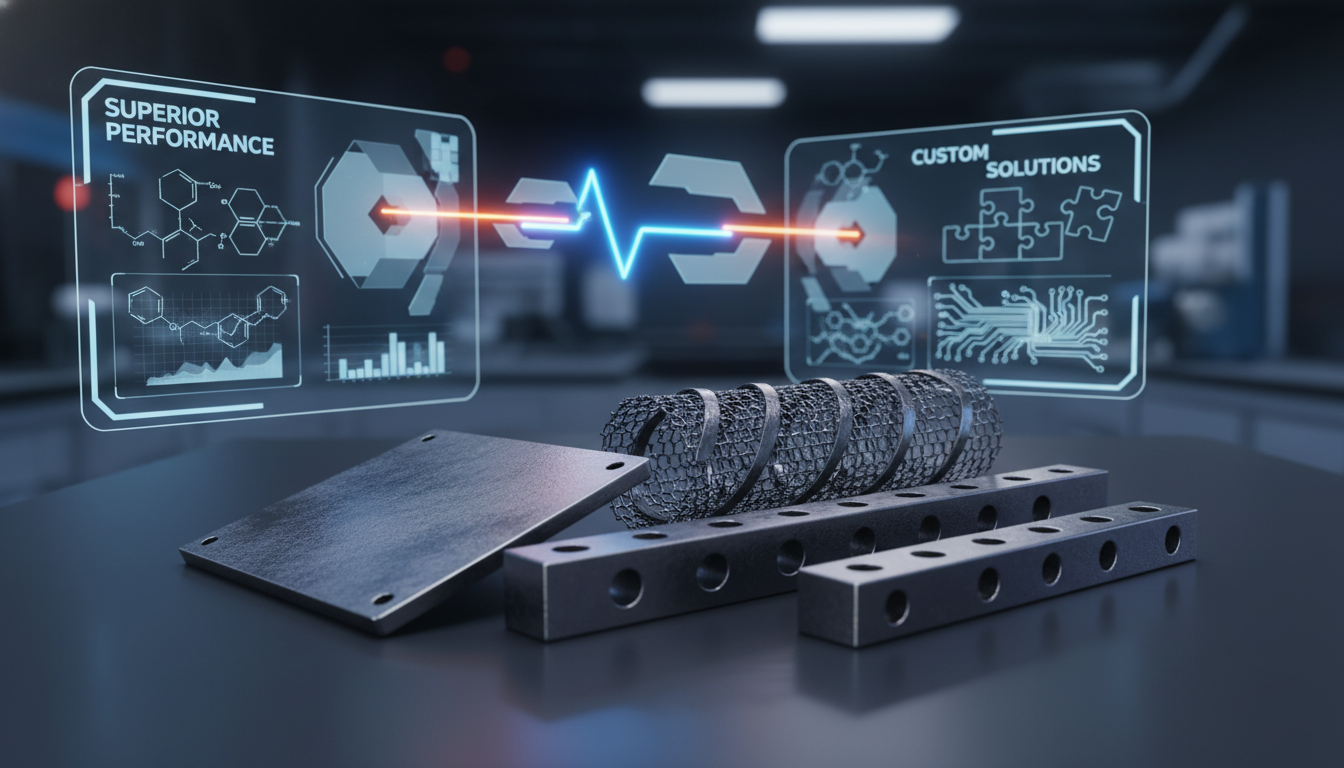

We are a premier provider of Ruthenium-Iridium coated titanium anodes, renowned for their exceptional durability and consistent performance in demanding industrial environments. Our Mixed Metal Oxide (MMO) anodes are engineered to deliver superior energy efficiency and reliability.

Request a Quote

Ruthenium-Iridium Coated Titanium Anodes (Ru-Ir Coated Titanium Anodes) are recognized as the industry standard for Chlorine Evolution Reaction (CER). Their active coating exhibits superior performance in brine electrolysis and seawater applications.

Precisely engineered to achieve unparalleled efficiency and lasting durability across diverse industrial applications, especially in chlorine-evolving environments.

Utilizing cutting-edge ruthenium-iridium thermal decomposition technology to ensure excellent conductivity and superior resistance to gas evolution.

Maintains a stable geometric shape throughout its service life, ensuring consistent electrode spacing and preventing electrolyte contamination.

Low chlorine evolution overpotential significantly reduces cell voltage, leading to substantial energy savings in large-scale

industrial processes.

| Coating Type | Primary Active Reaction | Typical Application Fields |

|---|---|---|

| Ru-Ir Mixed Oxide | Chlorine Evolution Reaction (CER) | Chlor-Alkali Industry, Sodium Hypochlorite Generators, Seawater Electrolysis, Brine Electrolysis |

| Ru-Ir-Sn Mixed Oxide | Enhanced Chlorine Evolution | High-concentration Brine Electrolysis, Specialized Chemical Production |

| Ru-Ti Mixed Oxide | Cost-Effective Oxidation | Swimming Pool Disinfection, Small-scale Water Treatment |

Substrate Material: Commercially Pure Titanium (Gr1, Gr2)

Common Shapes: Mesh, Plate, Tube, Rod, Ribbon, Wire, and Custom Assemblies.

Coating Process: Multiple-layer Thermal Decomposition (High-Temperature Sintering) for maximum adhesion.

Customization Service: Precision manufacturing based on specific operating parameters (current density, electrolyte composition, temperature, etc.).

The core component for producing chlorine and caustic soda through brine electrolysis with high efficiency.

Used in on-site generators for water disinfection, swimming pools, and industrial cooling water treatment.

Effective for anti-fouling in power plants and coastal industrial facilities by generating active chlorine from seawater.

Provides stable anodic reactions in various metal recovery and surface finishing processes.