Anodizing is an electrochemical process that modifies the surface of titanium to enhance its durability, appearance, and resistance to wear and corrosion. When titanium is anodized, an oxide layer forms on its surface. This oxide layer is not only protective but also allows for a range of color, which are achieved without adding dyes or pigments.

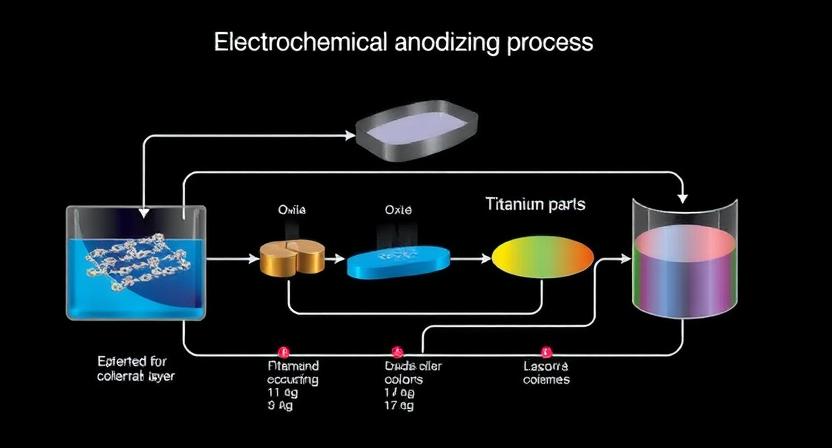

In essence, anodizing involves immersing titanium in an electrolytic bath and passing an electric current through it. This results in the formation of a titanium oxide layer on the surface. The thickness of the oxide layer can be controlled by adjusting the voltage used during anodizing, which in turn affects the color seen on the titanium surface.

The titanium anodizing process is methodical and involves several key steps to ensure quality and consistency. These steps are typically performed within specialized anodizing lines.

Before anodizing, the titanium surface must be meticulously cleaned to remove any contaminants, oils, or oxidation. This is typically done using an alkaline or acid bath to ensure the surface is pristine. Considering the best etching solution for titanium anodizing is crucial here.

The cleaned titanium is immersed in an electrolytic bath, often a mixture of sulfuric acid or phosphoric acid, forming the titanium anodizing solution. An electric current is then applied, creating an anodic film on the titanium surface. The thickness of the oxide and color of the film are controlled by varying the voltage. This anodizing titanium solution is key to the process.

By adjusting the voltage during anodizing, different colors can be achieved without the use of dyes. This is due to light interference with the oxide layer, which alters the perceived range of color. The higher the voltage, the thicker the oxide layer, and the different the color. This is how anodize titanium gets its vibrant hues.

After anodizing, the titanium may undergo a sealing process to enhance its corrosion resistance further. Finally, the anodized titanium is rinsed and dried, ready for use in its intended application. This results in a robust anodized titanium solution.

Anodized titanium is versatile and finds its place in several industries due to its enhanced properties and aesthetic flexibility.

In aerospace, anodized titanium is valued for its lightweight yet strong characteristics. Components like fasteners, airframe parts, and engine components benefit from the added corrosion resistance and durability. This is a prime example of anodizing work in critical applications.

The biocompatibility of anodized titanium makes it suitable for surgical instruments, dental implants, and orthopedic devices. Its non-reactive nature ensures safety in medical applications.

Anodized titanium's ability to display vibrant colors makes it a popular choice in the jewelry industry. It offers a unique aesthetic appeal while being hypoallergenic and durable, showcasing a wide range of color.

In the automotive sector, anodized titanium is used for high-performance parts like exhaust systems, suspension components, and trim pieces. Its resistance to heat and corrosion ensures longevity in demanding conditions.

When selecting a titanium anodizing solution, it's essential to consider the following:

Purpose: Determine whether the primary goal is aesthetic enhancement, increased durability, or corrosion resistance.

Environment: Consider the environmental conditions the anodized titanium will be exposed to, such as humidity, temperature, and exposure to chemicals.

Color Requirements: If specific colors are needed, ensure the anodizing process can achieve the desired hues and range of color.

Compliance: Ensure that the anodizing process meets industry standards and regulations, particularly for medical or aerospace applications. The quality of the titanium anode plates solution is also vital.

Titanium anodizing solutions offer significant advantages in terms of durability, aesthetic appeal, and versatility. By understanding the anodizing process and its benefits, industries can leverage anodized titanium to enhance product performance and appearance. Whether in aerospace, healthcare, or fashion, anodized titanium continues to be a preferred choice for its unique properties and visual allure.

By choosing the best solution for anodizing titanium, businesses can ensure their titanium products meet the highest standards of quality and functionality. As technology advances, the possibilities with anodized titanium continue to expand, promising even more innovative applications in the future. For those interested in how to make titanium anodizing solution or exploring titanium anodes: leading electrochemical solutions, further research into titanium anodizing electrolyte solution is recommended.

Author: Dr. Alex Chen, Materials Scientist specializing in surface engineering and corrosion resistance.

Credentials: Ph.D. in Materials Science, 15+ years experience in industrial anodizing processes and titanium applications.