Titanium square tubing represents a specialized and highly valued structural material meticulously crafted from titanium metal. It is designed with a distinctive square cross-section, available in a diverse range of sizes and thicknesses to fulfill the stringent demands of various industrial applications. This material is particularly celebrated for its exceptional strength-to-weight ratio, making it an indispensable choice across numerous sectors where both robust performance and minimal mass are critical.

The inherent characteristics of titanium metal form the bedrock of titanium square tubing's superior performance. Titanium boasts a remarkable strength-to-weight ratio, rivaling steel in strength while being significantly lighter. This fundamental property is crucial for applications requiring high structural integrity without the burden of excessive weight.

Exceptional Corrosion Resistance: Titanium's ability to form a passive, protective oxide layer (TiO₂) on its surface renders it highly resistant to corrosion, even in aggressive environments such as saltwater, acids, and chlorides. This feature ensures longevity and reduces maintenance in challenging conditions.

High-Temperature Tolerance: Titanium maintains its structural integrity and mechanical properties across a broad spectrum of temperatures, from cryogenic lows to extreme highs (up to 1650°C or 3000°F for certain alloys) [1]. This thermal stability is vital for aerospace, power generation, and high-temperature industrial processes.

Biocompatibility: A distinguishing feature of titanium is its excellent biocompatibility, meaning it does not provoke adverse reactions when in contact with biological tissues. This makes it the material of choice for medical implants and prosthetics.

Non-Magnetic Properties: Titanium is non-magnetic, which is a significant advantage in applications where magnetic interference must be avoided, such as in sensitive electronic equipment or medical imaging devices.

Excellent Formability and Weldability: Despite its strength, titanium can be readily formed and welded, allowing for complex designs and fabrication processes, though specialized techniques are often required to maintain its properties.

The square profile of titanium tubing offers specific structural benefits, including enhanced torsional rigidity and ease of connection, making it particularly advantageous in certain engineering designs. When combined with titanium's intrinsic properties, these advantages become even more pronounced.

Titanium square tubing provides extraordinary strength, capable of withstanding substantial pressure and stress. This makes it an ideal material for load-bearing structures and frameworks where structural integrity is paramount. Its durability ensures that components maintain their performance over extended periods, significantly reducing the need for frequent replacements and associated costs.

The lightweight nature of titanium square tubing is a critical advantage, especially in industries where weight reduction directly translates to improved performance and efficiency. Achieving the same strength as heavier metals like steel at a fraction of the weight leads to enhanced fuel efficiency in aerospace and automotive applications, and simplifies handling and installation processes in construction.

Titanium's inherent resistance to corrosion is a cornerstone benefit. Unlike many other metals, titanium square tubing remains unaffected by rust or degradation when exposed to moisture, saltwater, or harsh chemicals. This property is invaluable in marine, chemical processing, and offshore applications, extending the lifespan of structures and minimizing maintenance expenses. Furthermore, its inert nature prevents galvanic corrosion when paired with dissimilar metals.

The ability of titanium square tubing to perform reliably under extreme thermal conditions without compromising its mechanical properties makes it indispensable. This characteristic is particularly beneficial in aerospace engine components, industrial heat exchangers, and power generation systems, where consistent performance at elevated temperatures is crucial for safety and operational efficiency.

The versatility and robust properties of titanium square tubing enable its application across a broad spectrum of industries, addressing critical performance requirements.

In aerospace, where every gram counts, titanium square tubing is extensively used for aircraft frames, hydraulic systems, fuel lines, and structural supports. Its high strength-to-weight ratio, corrosion resistance, and thermal stability are vital for enhancing fuel efficiency, reducing overall aircraft weight, and ensuring safety in demanding flight conditions.

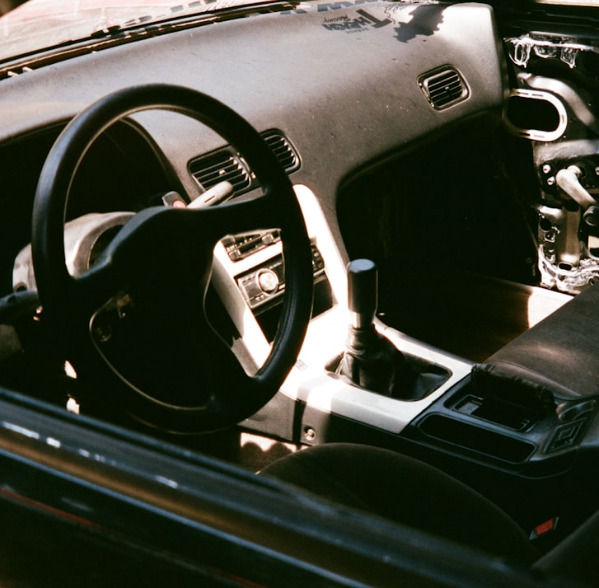

High-performance vehicles and motorsports leverage titanium square tubing for chassis components, exhaust systems, and roll cages. The material's lightweight nature contributes to improved power-to-weight ratios, enhanced handling, and better fuel economy, while its durability ensures long-term reliability.

Titanium square tubing is an ideal choice for marine environments due to its exceptional resistance to saltwater corrosion. It is employed in shipbuilding for structural elements, heat exchangers, subsea equipment, and offshore platforms, guaranteeing longevity and reducing maintenance in harsh oceanic conditions.

Given its biocompatibility and non-reactive nature, titanium square tubing is widely used in the medical sector for surgical instruments, orthopedic implants, prosthetics, and medical device housings. Its ability to integrate with biological tissues and resist sterilization processes makes it a safe and reliable material for critical medical applications.

Beyond its industrial uses, titanium square tubing is gaining popularity in modern architecture and design. Its aesthetic appeal, combined with its strength and durability, makes it suitable for decorative elements, facade structures, and high-end interior fittings, offering both functional and visual benefits [2].

In power generation, particularly in solar thermal and nuclear power plants, titanium square tubing can serve as structural support for receiver panels and heat exchange components. Its high melting point and excellent thermal stability are crucial for maintaining efficiency and safety in high-temperature energy conversion processes [3].

Titanium square tubing is available in various grades and specifications, allowing for tailored solutions to optimize performance for specific applications. Understanding these variations and sourcing considerations is key to successful project execution.

Commercially Pure (CP) Titanium (e.g., Grade 1, Grade 2): These grades offer excellent corrosion resistance, ductility, and formability. Grade 2 is a common choice for general industrial applications due to its good balance of strength and formability [4].

Titanium Alloys (e.g., Grade 5 / Ti-6Al-4V): Grade 5 is the most widely used titanium alloy, known for its superior strength, high fatigue resistance, and excellent fracture toughness. It is often preferred for high-performance applications in aerospace and medical fields [4].

Other Alloys: Specialized alloys exist for specific requirements, such as enhanced high-temperature strength or improved corrosion resistance in particular chemical environments.

Titanium square tubing is manufactured in a broad range of sizes, from small-diameter tubes for precision instruments to large-diameter sections for heavy-duty structural applications. Common dimensions include various side lengths (e.g., 1 inch, 2 inch, 3 inch, 4 inch) and wall thicknesses, with customization options readily available to meet unique project specifications [5, 6].

A comprehensive range of titanium pipe fittings, including elbows, tees, flanges, and connectors, are available to complement square tubing systems. These fittings are crucial for creating leak-proof connections and maintaining the overall integrity and performance of complex piping layouts.

Welding titanium square tubing requires specialized techniques to preserve its mechanical properties and corrosion resistance. Gas Tungsten Arc Welding (GTAW) and Plasma Arc Welding (PAW) are commonly employed methods. A critical aspect is maintaining a contamination-free welding environment to prevent oxidation and ensure the integrity of the weld joint. Proper training and specialized equipment are essential for achieving optimal results.

Installation considerations include precise pipe alignment, adequate support structures, and careful allowance for thermal expansion. Addressing these factors during installation is vital for maximizing the longevity, efficiency, and safety of titanium square tubing systems, thereby minimizing the risk of failure and costly repairs.

While titanium square tubing may have a higher initial cost compared to traditional materials like stainless steel, its long-term cost-effectiveness is often superior. The extended lifespan, minimal maintenance requirements, and resistance to degradation in harsh environments lead to significant savings over the product's lifecycle. Industries must consider the total cost of ownership, including reduced replacement and repair expenses, when evaluating material selection.

Sourcing titanium square tubing from reputable manufacturers and distributors is paramount to ensure product quality, authenticity, and adherence to industry standards. Trusted suppliers offer a wide range of stock sizes and customization options, providing materials that meet specific project needs and performance requirements. Partnering with experienced suppliers ensures access to high-quality materials and expert technical support.

Titanium square tubing stands out as a high-performance material offering a compelling combination of strength, lightweight properties, exceptional corrosion resistance, and high-temperature tolerance. Its versatility makes it an ideal choice for demanding applications across the aerospace, automotive, marine, medical, architectural, and power generation industries.

By understanding the specific grades, dimensions, and installation best practices, businesses can fully leverage the unique benefits of titanium square tubing. Investing in this advanced material, coupled with strategic sourcing from reliable manufacturers, ensures enhanced performance, extended longevity, and significant long-term cost savings for critical industrial and structural projects. Titanium square tubing is indeed a future-proof solution for modern engineering challenges.