High-quality titanium sheet metal, including Commercial Pure (CP) grades (1-4) and alloys like Ti-6Al-4V (Grade 5), is available for diverse industrial needs.

Titanium offers exceptional strength-to-weight ratio, superior corrosion resistance, and biocompatibility, making it ideal for aerospace, medical, and chemical processing applications.

The procurement process involves stringent quality assurance, adherence to international standards (e.g., ASTM, ISO), and full material traceability.

Custom sizing, thicknesses, and fabrication services are offered, supported by robust global shipping and logistics capabilities.

To buy titanium sheet metal, clients are encouraged to request a custom quote from a trusted global supplier.

The demand for high-performance materials in critical applications continues to expand globally. Industries such as aerospace, medical, and chemical processing require materials that offer an exceptional combination of strength, corrosion resistance, and lightweight properties. When companies need to buy titanium sheet metal, they often encounter challenges in sourcing reliable, high-quality products that meet stringent international standards. Inconsistent material properties, lack of certification, and unreliable supply chains can significantly impact project timelines and overall product integrity. Addressing these concerns requires a dedicated partner committed to excellence. This content serves as a premier global supplier of high-quality titanium sheet metal. The company provides a comprehensive range of grades and custom solutions designed to meet the rigorous demands of specialized applications worldwide. Clients can explore the extensive offerings and experience unparalleled quality and service, ensuring their projects benefit from the best available materials.

Titanium is a chemical element with the symbol Ti and atomic number 22, renowned for its excellent strength-to-weight ratio and superior corrosion resistance. Titanium sheet metal refers to thin, flat pieces of this versatile material, typically produced through a rolling process. Its fundamental characteristics make it indispensable across numerous sectors. Key properties of titanium include:

High Strength-to-Weight Ratio: Titanium is as strong as some steels but 45% lighter, making it ideal for applications where weight reduction is critical.

Exceptional Corrosion Resistance: It forms a passive oxide layer that protects it from various corrosive environments, including seawater, chlorine, and many acids. This property is extensively detailed by sources like Wikipedia.

Biocompatibility: Titanium is non-toxic and compatible with human tissue, leading to its widespread use in medical implants.

High Melting Point: With a melting point of 1,668 °C (3,034 °F), it maintains structural integrity at elevated temperatures.

The production of titanium sheet metal involves several stages, beginning with the extraction of titanium ore (primarily rutile and ilmenite). The ore is processed into titanium sponge, which is then melted, often in a vacuum arc remelting (VAR) furnace, to produce ingots. These ingots are subsequently hot-rolled and then cold-rolled to achieve the desired sheet thickness and surface finish. Precision annealing and finishing treatments are applied to optimize mechanical properties and ensure dimensional accuracy.

Selecting the right supplier for titanium sheet metal is a critical decision that impacts project success and material performance. This company distinguishes itself through an unwavering commitment to quality, adherence to international standards, and exceptional customer service. Key advantages include:

Stringent Quality Control: Every batch of titanium sheet metal undergoes rigorous testing and inspection to ensure it meets or exceeds specified mechanical properties and chemical compositions.

International Standard Compliance: Materials are produced in strict accordance with recognized international standards such as ASTM, ISO, and AMS, guaranteeing consistency and reliability.

Comprehensive Certifications: Full material certifications are provided with every order, offering complete traceability from raw material to finished product.

Expert Technical Support: A dedicated team of material science experts is available to assist clients with material selection, technical specifications, and application-specific guidance.

Reliable Global Supply Chain: The company’s robust logistics network ensures timely and secure delivery of titanium sheet metal to clients worldwide, minimizing delays and optimizing project schedules.

These factors collectively provide assurance that clients are receiving premium-grade titanium sheet metal backed by a commitment to excellence.

The extensive inventory of titanium sheet metal features a diverse array of grades, each tailored for specific performance requirements and industrial applications. Understanding the characteristics of each grade is essential for optimal material selection. This section provides an overview of the primary offerings, preparing clients for a detailed comparison of properties and applications.

Commercial Pure (CP) titanium grades are unalloyed forms of titanium, differentiated by their oxygen and iron content, which influences their strength and ductility.

CP Grade 1: The softest and most ductile of the CP grades, offering excellent formability and corrosion resistance. It is commonly used in chemical processing, marine, and medical applications where high ductility is paramount.

CP Grade 2: The most widely used CP grade, balancing good strength with excellent ductility and weldability. Its versatility makes it suitable for heat exchangers, architectural components, and general industrial applications.

CP Grade 3: A medium-strength CP grade, offering higher mechanical properties than Grade 2 but with slightly reduced ductility. It finds applications in pressure vessels and aerospace components requiring moderate strength.

CP Grade 4: The strongest of the CP grades, known for its high strength and good corrosion resistance, though with lower ductility than the other CP grades. It is often utilized in surgical implants, airframe components, and chemical processing equipment.

Titanium alloys combine titanium with other elements to enhance specific properties such as strength, heat resistance, and fatigue life.

Ti-6Al-4V (Grade 5): This is the most common and widely recognized titanium alloy, accounting for over 50% of all titanium usage. It is celebrated for its exceptional strength, lightweight properties, and excellent corrosion resistance. Ti-6Al-4V is heat-treatable, allowing for further optimization of its mechanical properties. Its widespread use in aerospace, automotive, and high-performance applications is well-documented by industry bodies such as ASM International.

Other Specialized Alloys: The company also offers other advanced titanium alloys designed for specific niche applications requiring enhanced properties such as higher temperature resistance or improved fracture toughness. These include alloys like Ti-5Al-2.5Sn (Grade 6) for elevated temperature service and Ti-0.3Mo-0.8Ni (Grade 12) for enhanced crevice corrosion resistance.

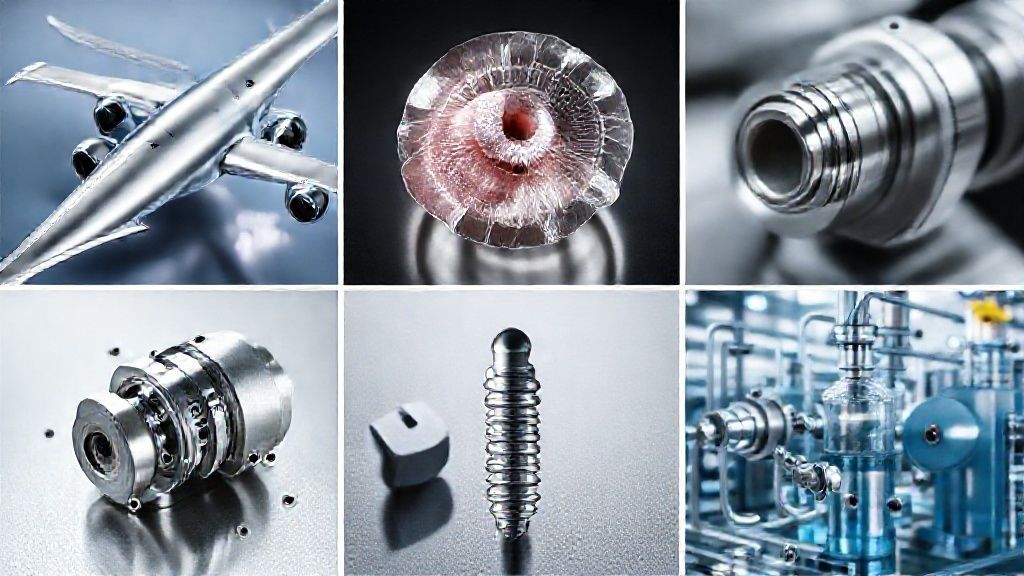

Titanium sheet metal's unique combination of properties makes it a transformative material across a multitude of sectors. Its ability to solve complex engineering challenges drives its adoption in critical applications globally.

The aerospace and defense sectors are primary consumers of titanium sheet metal. Its lightweight and high-strength characteristics are indispensable for performance, fuel efficiency, and safety.

Aircraft Structural Components: Used in wings, fuselages, landing gear, and fasteners for commercial and military aircraft.

Engine Parts: Critical for jet engine compressor blades, discs, and casings due to its ability to withstand high temperatures and stresses.

Spacecraft and Missile Systems: Employed in propulsion systems, structural frames, and re-entry vehicles for its durability in extreme conditions.

Titanium's unparalleled suitability for medical and biomedical applications stems from its biocompatibility, corrosion resistance, and non-toxicity.

Surgical Implants: The material of choice for orthopedic implants such as hip and knee replacements, spinal fusion devices, and bone plates.

Prosthetics: Used in lightweight and durable prosthetic limbs and dental implants.

Advanced Medical Devices: Employed in surgical instruments and various diagnostic equipment.

The National Institutes of Health (NIH) provides extensive research on the biocompatibility of titanium for medical applications, highlighting its inertness and ability to integrate with bone tissue, as shown in publications found on PubMed.gov.

Titanium sheet metal excels in harsh industrial and chemical processing environments where resistance to aggressive media is paramount.

Chemical Processing Equipment: Used for tanks, heat exchangers, valves, and piping in highly corrosive chemical plants.

Marine Applications: Ideal for shipbuilding, offshore platforms, and subsea equipment due to its resistance to saltwater corrosion.

Power Generation: Employed in condensers and heat exchangers within power plants, particularly those using seawater for cooling.

Navigating the process of acquiring titanium sheet metal can be simplified with a clear, step-by-step guide. The company aims to ensure a smooth and efficient procurement experience for its global clientele. The typical purchasing process involves:

Initial Inquiry: Clients submit their requirements, including grade, dimensions, quantity, and specific application details.

Consultation and Quotation: Expert sales engineers review the specifications, provide technical recommendations, and issue a competitive, custom quote. For direct assistance, please contact the sales team.

Order Confirmation: Upon acceptance of the quote, the order is confirmed, and production or allocation from inventory begins.

Quality Assurance & Certification: Materials undergo final quality checks and are prepared with full documentation, including Mill Test Certificates. Additional details about the company's commitment to quality can be found on the Quality Assurance page.

Packaging & Shipping: Products are securely packaged and dispatched via the chosen logistics method.

Delivery & Support: The material arrives at the client's location, with ongoing support available for any post-delivery inquiries.

Projects often require titanium sheet metal tailored to exact specifications. The company offers extensive customization options to meet unique requirements.

Custom Dimensions: Clients can specify precise lengths and widths for their sheet metal orders.

Variety of Thicknesses: A broad range of thicknesses is available, from ultra-thin foils to heavy plates.

Specialized Fabrication: Services include precision cutting (laser, waterjet, plasma), forming, bending, and machining to deliver ready-to-use components. Information on specific capabilities is available on the fabrication services page.

A robust global shipping and logistics network ensures efficient and secure delivery of titanium sheet metal to clients across the world.

International Delivery Options: Various shipping methods are available, including air freight for urgent orders and sea freight for larger volumes, balancing speed and cost.

Lead Times: Realistic lead times are provided at the quotation stage, ensuring transparency and predictability.

Secure Packaging: All materials are professionally packaged to prevent damage during transit, adhering to international shipping standards.

Customs Clearance Support: Assistance with necessary documentation and customs procedures is provided to facilitate smooth international delivery.

The unwavering commitment to quality is a cornerstone of the company's operations. This commitment is underpinned by rigorous testing, adherence to international standards, and complete material traceability.

Rigorous Testing Protocols: Each batch of titanium sheet metal undergoes comprehensive mechanical testing (tensile strength, yield strength, elongation), chemical analysis, and non-destructive testing (NDT) to verify material integrity.

Adherence to International Standards: Products conform to major international specifications, including ASTM B265 for Titanium and Titanium Alloy Strip, Sheet, and Plate. The ASTM International organization sets many of these critical material standards.

ISO Certification: Manufacturing processes are certified to ISO 9001, demonstrating a commitment to consistent quality management systems.

Full Material Traceability: Every piece of titanium sheet metal can be traced back to its original melt, ensuring accountability and transparency throughout the supply chain. Mill Test Certificates (MTCs) are provided with every shipment.

These measures collectively ensure that every sheet of titanium delivered meets the highest performance and safety benchmarks required by demanding industries.

To assist clients in material selection and project planning, a suite of interactive tools and comprehensive resources is available. These resources are designed to facilitate informed decision-making and streamline the procurement process.

Titanium Weight Calculators: Tools to estimate the weight of titanium sheets based on dimensions and density, aiding in logistics and cost estimation.

Grade Comparison Charts: Detailed tables comparing the mechanical properties, chemical compositions, and typical applications of various titanium grades.

Technical Data Sheets: Downloadable documents providing in-depth specifications for each titanium product.

Application Guides: Resources offering insights into the optimal use of different titanium grades across various industries.

These tools empower engineers, procurement specialists, and project managers to efficiently specify and procure the correct titanium material for their projects.

The company is committed to environmental stewardship and ethical practices throughout the titanium supply chain. Efforts are focused on ensuring that the sourcing and production of titanium sheet metal are conducted responsibly.

Sustainable Manufacturing Initiatives: Implementation of energy-efficient processes and waste reduction strategies in manufacturing operations.

Responsible Supply Chain Management: Working with suppliers who adhere to ethical labor practices and environmental regulations, ensuring conflict-free sourcing of raw materials.

Recycling Programs: Active participation in and promotion of titanium recycling to reduce the demand for virgin materials and minimize environmental impact.

Environmental Impact Reduction: Continuous efforts to lower the carbon footprint associated with titanium production and transportation.

These initiatives reflect a commitment to contributing positively to both the environment and society while supplying high-quality industrial materials.

Confidence in a supplier is often built upon the experiences of other satisfied clients. This section highlights authentic customer testimonials and compelling case studies, showcasing successful applications of the company's titanium sheet metal in diverse and challenging projects.

"The titanium sheet metal supplied for our aerospace project exceeded all specifications. The material consistency and accompanying certifications were impeccable, ensuring smooth integration into our manufacturing process." - Lead Engineer, Aerospace Manufacturer

"For our medical implant development, the biocompatibility and precision of the CP Grade 2 titanium were critical. The support team provided invaluable technical guidance, leading to a successful product launch." - R&D Director, Medical Device Company

These testimonials underscore the reliability, quality, and technical expertise that clients receive when partnering with the company for their titanium material needs.

Titanium sheet metal offers a superior strength-to-weight ratio, exceptional corrosion resistance, high biocompatibility, and excellent performance in high-temperature environments. These properties make it ideal for demanding applications where durability and weight reduction are critical.

Commercial Pure (CP) titanium consists of unalloyed titanium, with grades (1-4) varying primarily by oxygen and iron content, affecting strength and ductility. Titanium alloys, such as Ti-6Al-4V (Grade 5), combine titanium with other elements (e.g., aluminum, vanadium) to enhance specific mechanical properties like strength, heat treatability, and fatigue resistance.

Ensuring quality involves verifying supplier certifications (e.g., ISO 9001), requesting Mill Test Certificates (MTCs) for full material traceability, and confirming adherence to international standards like ASTM and AMS. Reputable suppliers conduct rigorous testing and provide comprehensive documentation for all products.

Yes, custom dimensions, thicknesses, and specialized fabrication services are typically available. These services often include precision cutting (laser, waterjet), forming, bending, and machining to meet specific project requirements. Clients should discuss their exact needs with the supplier's sales or engineering team.

Titanium sheet metal is widely used in aerospace and defense (aircraft, spacecraft), medical and biomedical (implants, surgical instruments), chemical processing (tanks, heat exchangers), marine (subsea equipment), and automotive (high-performance components) industries due to its unique properties.

Do not compromise on quality or reliability for your critical projects. Partner with a trusted global supplier for certified, high-performance titanium sheet metal tailored to your exact specifications. Get the materials that ensure success.

Request a Custom Quote