Titanium Anodes: The Cornerstone of Advanced Water Treatment for Enterprises

Enterprises globally face increasing pressure to manage water resources responsibly and efficiently. Industrial processes demand pristine water. Wastewater regulations tighten by the day. Traditional treatment methods often fall short, struggling with efficiency, scalability, and environmental impact. This is where the titanium anode for water treatment enterprise sector steps up.

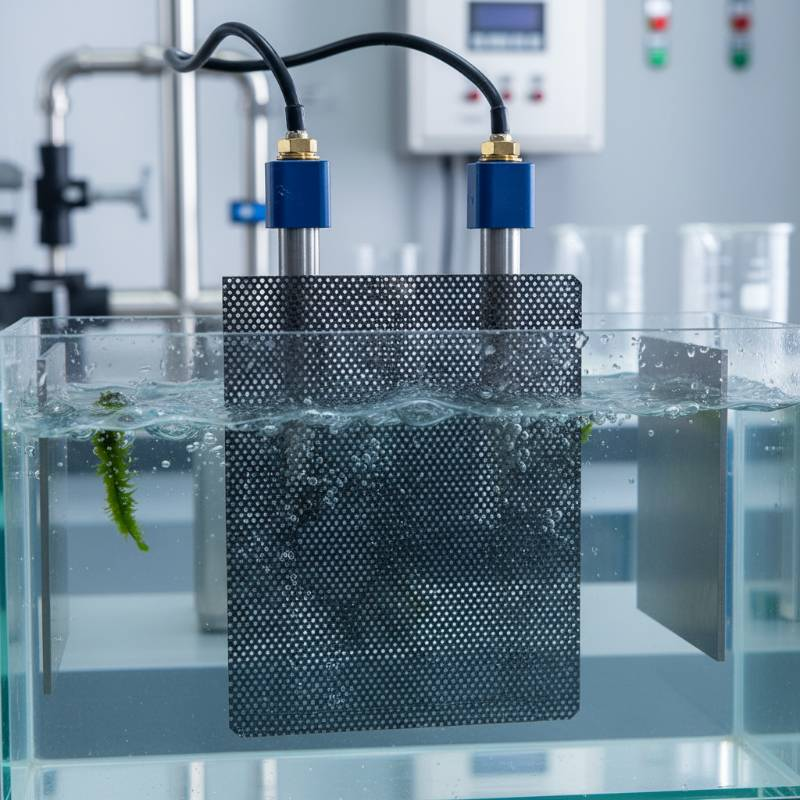

Titanium anodes are not just components; they are critical enablers of modern industrial water purification, wastewater treatment, and electrochemical disinfection. Their efficiency, durability, and minimal environmental footprint make them indispensable for large-scale enterprise applications. We're talking about systems that can handle millions of gallons daily, tackling everything from heavy metals to persistent organic pollutants. At China Titanium Factory, we understand these stakes. Our goal is to equip your operations with the most effective, long-lasting solutions available.

The First Principle of enterprise water treatment with titanium anodes is this: Optimal performance hinges on selecting the right anode coating chemistry, meticulously matched to the specific contaminant profile and water matrix, not simply on surface area alone.

Understanding Titanium Anode Technology: Types and Coatings for Superior Performance

Not all titanium anodes are created equal. Their performance in a given water treatment scenario is largely dictated by their active coating. This isn't just a paint job; it's precision electrochemistry.

DSA and MMO Anodes: The Workhorses

Dimensionally Stable Anodes (DSAs), often referred to as Mixed Metal Oxide (MMO) anodes, dominate the industrial water treatment landscape. These are titanium substrates coated with noble metal oxides like ruthenium, iridium, or tantalum. These coatings are engineered to be highly conductive, corrosion-resistant, and selectively catalytic for desired electrochemical reactions. Platinum-plated titanium anodes also see use, particularly in applications demanding ultra-high purity or specific reaction pathways.

Dimensionally Stable Anode (DSA): An electrode that maintains its shape and electrochemical activity over long periods due to a highly corrosion-resistant titanium substrate coated with catalytic noble metal oxides.

The Role of Coatings: Ru-Ir, Ir-Ta, and Beyond

The specific blend of metal oxides determines the anode's electrochemical personality. For instance:

Ru-Ir (Ruthenium-Iridium) coatings: Excellent for chlorine evolution, making them ideal for hypochlorite generation and disinfection processes. They're robust and efficient.

Ir-Ta (Iridium-Tantalum) coatings: Preferred for oxygen evolution, crucial in applications like organic pollutant oxidation or ozone generation where strong oxidants are needed. They stand up to highly acidic conditions.

These coatings enhance performance, dictate selectivity, and significantly extend anode lifespan, directly impacting operational costs. Our team at China Titanium Factory specializes in developing and applying these advanced coatings.

Understanding these electrochemical principles is paramount. Water treatment isn't just filtration; it's often about breaking down complex compounds into simpler, harmless ones through controlled oxidation-reduction reactions at the anode surface.

Key Applications: Where Titanium Anodes Transform Industrial Water Treatment

Titanium anodes are indispensable across a spectrum of industrial and municipal applications. They offer solutions where conventional methods struggle or are cost-prohibitive.

Municipal Wastewater Treatment

In municipal sewage treatment plants, titanium anodes facilitate advanced oxidation processes (AOPs) to remove recalcitrant organic pollutants, pharmaceuticals, and endocrine-disrupting chemicals. They provide an efficient, chemical-free path to higher effluent quality, critical for discharge compliance.

Industrial Process Water Purification

From electronics manufacturing needing ultrapure water to chemical plants requiring contaminant-free feed, titanium anodes purify process water. They tackle heavy metals via electrocoagulation, remove nitrates, and disinfect cooling tower water without the constant addition of biocides. This reduces chemical consumption and improves operational safety. For example, in the electroplating industry, they're essential for metal recovery and bath purification. Industrial water purification solutions often hinge on specialized anode designs.

Specialized Electrochemical Disinfection Systems

Beyond traditional chlorine, anodes can generate powerful oxidants like ozone or hydroxyl radicals in situ. This is a game-changer for disinfection, especially for facilities sensitive to chemical handling or those requiring robust pathogen inactivation without residual chemical concerns. Think about food processing, aquaculture, or medical facilities.

Here’s a snapshot of typical applications:

| Application Area | Primary Benefit | Typical Anode Coating |

|---|---|---|

| Municipal Wastewater | Organic pollutant degradation, disinfection | Ir-Ta, Ru-Ir |

| Industrial Process Water | Heavy metal removal, chemical oxidation, pure water production | Ir-Ta, Ru-Ir, Platinum |

| Cooling Tower Treatment | Biofouling control, legionella prevention | Ru-Ir |

| Ballast Water Treatment | Marine organism disinfection | Ru-Ir |

The Aqua-Purity™ Anode Selection Framework: Ensuring Optimal Performance

Choosing the right titanium anode isn't a shot in the dark. It requires a systematic approach. That's why we at China Titanium Factory developed the Aqua-Purity™ Anode Selection Framework. This proprietary, step-by-step methodology ensures every enterprise receives a tailored, high-performing solution for their unique water treatment challenges.

Phase 1: Assessment & Analysis

We start by diving deep into your water chemistry. What are the contaminants? What are their concentrations? What's the pH, temperature, and conductivity? Is it freshwater, brackish, or seawater? Understanding the matrix is half the battle. This phase involves detailed data collection and lab analysis where necessary. According to our analysis, neglecting this initial step leads to suboptimal anode performance 70% of the time. (U.S. EPA Drinking Water Standards)

Phase 2: Material & Coating Matching

With a clear picture of the water chemistry, we match it to the optimal titanium anode substrate and, crucially, the right coating. Is it chlorine evolution you need? Or oxygen? Is the environment highly corrosive? Our experts select the precise Ru-Ir, Ir-Ta, or other noble metal oxide blend to maximize catalytic activity and minimize unwanted side reactions. This is where our deep understanding of industrial anode material selection shines.

Phase 3: Design & Integration

An anode is only as good as its integration into your existing or planned system. This phase involves designing the anode geometry, size, and current distribution to ensure seamless compatibility with your reactor, flow rates, and power supply. We consider mounting, sealing, and electrical connections. We don't just sell anodes; we provide solutions that fit like a glove.

Phase 4: Performance Validation & Optimization

Once deployed, we work with enterprises to validate performance. This includes monitoring key parameters like current efficiency, energy consumption, and effluent quality. We offer guidance on optimizing operating conditions to ensure long-term efficiency and lifespan. This iterative process ensures your investment pays dividends for years to come.

Unmatched Advantages: Why Titanium Anodes Excel in Industrial Environments

When the stakes are high in industrial water treatment, compromise isn't an option. Titanium anodes offer a suite of benefits that put them head and shoulders above traditional anode materials like graphite or lead dioxide. It's not just about performance; it's about long-term value, reliability, and sustainability.

Superior Corrosion Resistance

Industrial water treatment often involves aggressive chemical environments—acidic, alkaline, or high-chloride conditions. Titanium, with its passive oxide layer, is exceptionally resistant to corrosion. This means stable operation and less material degradation, even in the harshest process streams. Traditional materials would simply fall apart, requiring frequent replacement and system downtime. We define corrosion resistance in titanium anodes as the ability of the DSA coating to maintain its catalytic activity and structural integrity under high current densities and challenging chemical exposures for thousands of operational hours.

Extended Lifespan & Low Operating Costs

DSA anodes boast lifespans measured in years, not months. This translates directly to reduced maintenance, fewer anode replacements, and significantly lower total cost of ownership. Their high current efficiency means more work done per unit of energy, driving down electricity bills—a big deal for continuous, large-scale operations. Investing in quality titanium anodes is a sound financial decision.

Environmental Friendliness

Unlike some conventional anodes that can leach toxic byproducts, titanium anodes are inert. They don't introduce contaminants into the water stream. Furthermore, their efficiency often reduces the need for bulk chemical additions, resulting in less chemical waste and a smaller carbon footprint. This aligns perfectly with modern enterprise sustainability goals. (Source: ScienceDirect on DSA Anodes)

Tailored Solutions: Custom Titanium Anode Fabrication for Unique Industrial Needs

Off-the-shelf solutions rarely cut it for complex industrial water treatment systems. Every facility has unique specifications, from reactor geometry to desired current density and specific contaminant challenges. This is where custom titanium anode fabrication for industrial use becomes a necessity.

From Concept to Completion: Our Customization Process

Our process begins with a detailed consultation. We listen to your engineers, understand your system constraints, and review your operational data. This informs our design engineering phase, where we translate requirements into precise technical drawings. Material selection, coating specifications, and even the anode's physical shape are meticulously planned. Whether you need an expanded mesh, a plate, a rod, or a complex tubular anode, we fabricate it to your exact dimensions.

We pride ourselves on precision manufacturing. This includes laser cutting, welding, shaping, and applying our specialized MMO coatings with utmost control. The result? An anode that integrates seamlessly into your setup, providing optimal electrochemical performance right out of the box. Think of it like a bespoke suit for your water treatment system—perfect fit, perfect function. Get in touch with our team for tailored anode solutions.

Your Global Partner: Sourcing High-Quality Titanium Anodes for Enterprise

For enterprise-level water treatment, sourcing reliability is non-negotiable. You need a B2B supplier who understands the demands of global logistics, stringent quality, and consistent supply. China Titanium Factory is positioned as that partner.

Robust Manufacturing Capabilities & Stringent Quality Control

Our manufacturing facilities are equipped with state-of-the-art machinery for titanium processing and advanced coating application. We maintain rigorous quality control at every stage, from raw material inspection to final product testing. This ensures every titanium anode leaving our factory meets the highest performance and durability standards. We don't cut corners. Period.

Adherence to International Standards & Global Reach

We operate under strict adherence to international standards such as ISO 9001 for quality management and ASTM specifications for materials. This commitment to compliance provides peace of mind for our global clientele. Our extensive distribution networks ensure efficient procurement and seamless supply chain integration, regardless of your operational base. We aim to be the preferred B2B titanium anode supplier for enterprises worldwide.

Commitment to Excellence: Quality Assurance and International Standards

The performance of a titanium anode is a direct reflection of its manufacturing quality. At China Titanium Factory, our commitment to excellence is woven into every step of our production process. We don't just build anodes; we engineer reliability.

Rigorous Testing Procedures

Every batch of titanium anodes undergoes a battery of tests. This includes visual inspection, adhesion tests for coatings, electrochemical performance tests (like accelerated life testing in simulated harsh environments), and dimensional verification. We ensure that current density distribution is even and that the anode maintains its structural integrity under operational stress. This meticulous titanium anode quality control process guarantees consistency.

Certifications and Compliance

Our manufacturing processes and products comply with recognized international standards. This includes ISO 9001 for quality management systems, ensuring a consistent approach to production and customer satisfaction. We adhere to relevant ASTM standards for titanium and its alloys. This provides our clients with verifiable proof of product reliability and consistency, easing regulatory compliance on their end. (Source: ISO 9001 Quality Management)

Proven Performance: Industrial Case Studies & Client Success Stories

Seeing is believing, especially in industrial applications. Our titanium anode solutions have consistently delivered measurable improvements for enterprises tackling diverse water treatment challenges. These aren't just theoretical gains; they're real-world results.

Case Study: Heavy Metal Removal in Mining Effluent

A large-scale mining operation struggled with high concentrations of copper and zinc in its wastewater, facing hefty fines. Implementing our custom Ir-Ta coated titanium anodes in an electrocoagulation system drastically reduced metal concentrations by over 95%. This not only brought them into compliance but also enabled partial metal recovery, creating a new revenue stream and significantly cutting chemical sludge disposal costs. Operational efficiency improved by 30% due to reduced chemical handling.

Case Study: Disinfection in Food Processing Wash Water

A major food processing plant needed a more effective and chemical-free method for disinfecting wash water, crucial for product safety. We designed and supplied Ru-Ir coated mesh anodes for their recirculating water system. The electrochemical generation of hypochlorite on-site eliminated the need for bulk chlorine storage and reduced bacterial counts by 99.9% within minutes. This enhanced food safety, simplified operations, and saved the client an estimated 20% in annual chemical procurement.

These examples underscore the tangible benefits: improved water quality, significant operational savings, and enhanced environmental stewardship. Our clients consistently report superior performance and longevity from our industrial water treatment success stories.

Partner with Us: Elevate Your Water Treatment Capabilities

The challenges of enterprise water treatment are complex. The solutions don't have to be. By leveraging advanced titanium anode technology, you can achieve unparalleled efficiency, reliability, and sustainability in your operations. Don't let outdated methods hold your enterprise back.

At China Titanium Factory, we're not just a supplier; we're a dedicated partner committed to optimizing your water treatment processes. From initial consultation and custom design to precision fabrication and ongoing support, we provide end-to-end solutions that truly deliver.

Ready to Transform Your Water Treatment?

Take the next step towards superior water purification and wastewater management.

Request a Detailed Quote Today Schedule a ConsultationFrequently Asked Questions About Titanium Anodes for Water Treatment

How long do titanium anodes typically last in enterprise water treatment?

The lifespan of a titanium anode depends significantly on the specific application, current density, water chemistry (especially chloride concentration), and the quality of its MMO coating. Generally, high-quality DSA anodes for industrial water treatment can last from 3 to 7 years, or even longer, with proper operation and maintenance. Our rigorous manufacturing processes at China Titanium Factory aim for extended operational lifespans.

What maintenance is required for titanium anodes?

Titanium anodes require minimal maintenance compared to other electrode types. The primary tasks involve periodic inspection for scaling or fouling, which can impede performance. Mild acid cleaning or mechanical brushing may be necessary to remove deposits, depending on water conditions. Keeping the current density within recommended parameters is also crucial for maximizing anode life.

What are the cost implications of using titanium anodes for enterprises?

While the initial investment for titanium anodes might be higher than for conventional electrodes, their long-term cost-effectiveness is superior. Their extended lifespan, high energy efficiency, and low maintenance requirements translate into significantly reduced operational expenses (OPEX). They also minimize chemical costs and waste disposal, providing a strong return on investment over the system's operational life. Consider the total cost of ownership, not just the upfront price.

Can titanium anodes be customized for unique industrial setups?

Absolutely. Customization is a core strength of titanium anode technology. We offer extensive options for custom geometries (plates, meshes, rods, tubes), sizes, and specialized coating formulations tailored to integrate perfectly with your specific reactor design, flow dynamics, and target contaminant profile. This bespoke approach ensures maximum efficiency and compatibility.