Understanding Titanium Ribbon Anodes: The Foundation of Modern Cathodic Protection

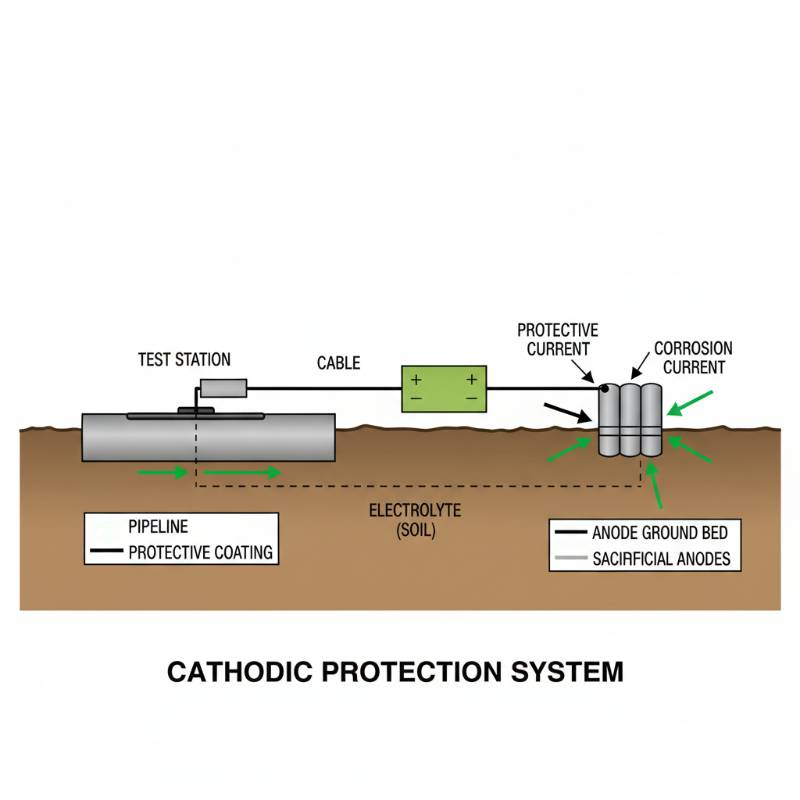

Corrosion isn't just a nuisance; it's a structural killer. For industries relying on buried pipelines, reinforced concrete, or submerged marine assets, unchecked degradation means catastrophic failures, environmental hazards, and staggering financial losses. The answer? Impressed current cathodic protection (ICCP), and at its heart, the titanium ribbon anode for cathodic protection stands as the undisputed champion.

These specialized anodes are a critical component in preventing corrosion. They deliver a precisely controlled electrical current to structures, effectively transforming them into a cathode and halting the electrochemical reactions that cause rust and material loss. It’s a proactive defense, not a reactive repair.

We define a titanium ribbon anode as a highly efficient, durable electrode, typically featuring a Mixed Metal Oxide (MMO) coating. It’s engineered to perform reliably under challenging conditions, ensuring the long-term integrity of vital infrastructure. This isn't just about delaying the inevitable; it's about fundamentally altering the corrosion process.

The Electrochemical Mechanism: How Titanium Ribbon Anodes Deliver Superior Protection

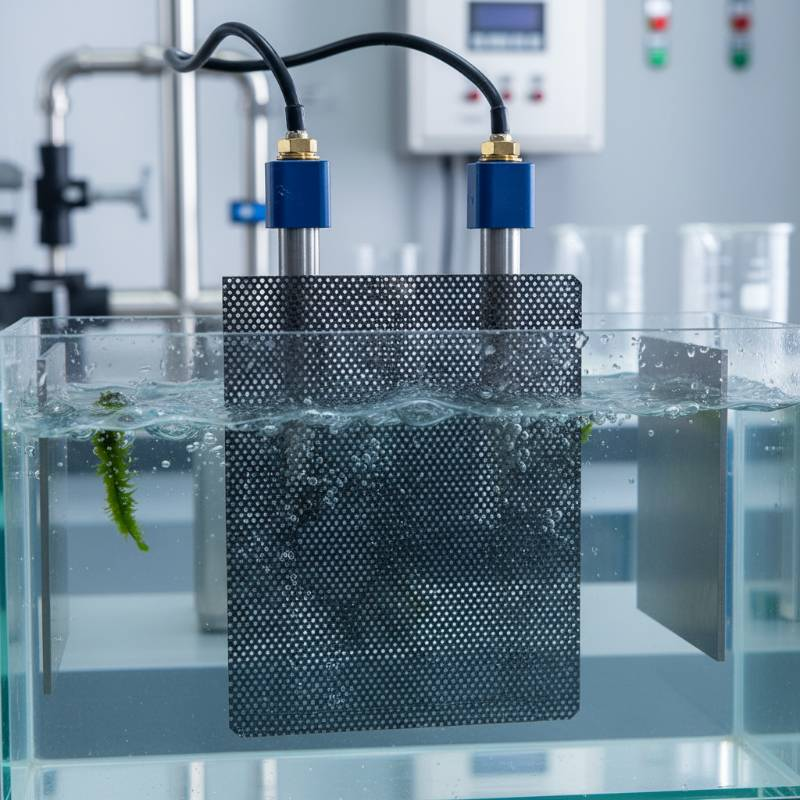

Understanding how titanium ribbon anodes work requires a quick dive into electrochemistry. Corrosion occurs when a metal acts as an anode in an electrochemical cell, losing electrons and forming metallic ions. Cathodic protection reverses this. We introduce an external anode and an external DC power source.

The titanium ribbon anode, connected to the positive terminal of a DC rectifier, becomes the active site for oxidation. The structure we're protecting (e.g., a pipeline), connected to the negative terminal, becomes the cathode. Electrons flow from the anode, through the electrolyte (soil, water, concrete), to the protected structure. This electron supply effectively stops the structure from corroding.

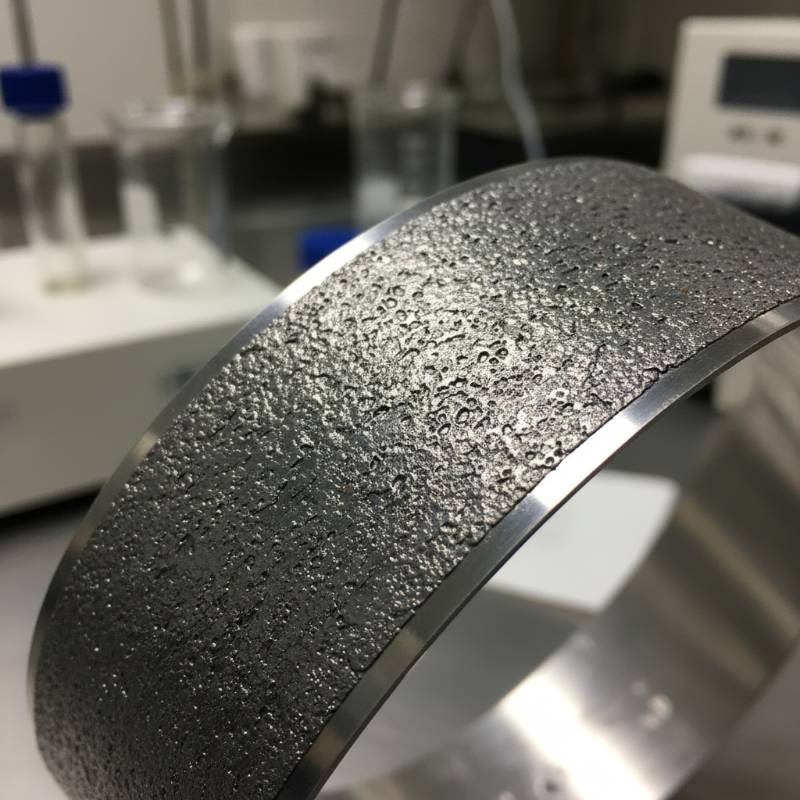

Mixed Metal Oxide (MMO) Coating: An electrocatalytically active layer, typically composed of iridium oxide and tantalum oxide, applied to a titanium substrate. This coating significantly enhances the anode's conductivity, lowers its consumption rate, and allows for high current output in various electrolytes, thereby extending its operational lifespan.

The MMO coating is the secret sauce. It facilitates the electrochemical reaction (usually oxygen evolution or chlorine evolution, depending on the environment) at the anode's surface with minimal degradation to the anode itself. This translates to consistent current distribution and long-term performance. Without this coating, the bare titanium would passivate quickly, rendering it ineffective.

Unrivaled Advantages: Why Specify Titanium Ribbon Anodes for Your Critical Assets

Choosing the right anode material is non-negotiable for effective corrosion control. Titanium ribbon anodes aren't just an option; they're often the best-in-class solution, especially for extensive or complex structures. Their benefits are substantial:

Exceptional Longevity: Thanks to their inert titanium substrate and robust MMO coating, these anodes boast operational lifespans often exceeding 20-50 years. This drastically reduces the frequency and cost of replacements.

High Current Output Efficiency: They can deliver substantial current densities with minimal voltage drop. This makes them ideal for protecting large areas, even in challenging environments like high-resistivity soil or concrete.

Low Consumption Rate: The MMO coating ensures a very low consumption rate, meaning the anode itself degrades extremely slowly. More current goes to protection, less to anode wastage.

Mechanical Robustness: Titanium is strong. The ribbon form factor allows for flexible yet durable installation, resisting mechanical damage during deployment and throughout its service life.

Versatility: From buried pipelines and storage tank bottoms to reinforced concrete bridges and marine jetties, their adaptability across diverse environments is a huge plus.

Cost-Effectiveness: While initial investment might be higher than sacrificial anodes, the extended lifespan, reduced maintenance, and superior protection translate to a significantly lower total cost of ownership over the project's life. This is a big deal for long-term budget planning.

Comprehensive Product Overview: Types, Coatings, and Technical Specifications

Not all titanium ribbon anodes are created equal. Their effectiveness hinges on precise manufacturing and the correct selection for the application. At China Titanium Factory, we prioritize material excellence and application-specific engineering.

The core component is the titanium substrate, typically Grade 1 or Grade 2, chosen for its excellent mechanical properties and resistance to passivation. The magic, however, lies in the Mixed Metal Oxide (MMO) coating. Common MMO formulations include:

Iridium/Tantalum Oxide: High performance in diverse electrolytes, including seawater, freshwater, and various soils.

Ruthenium/Iridium Oxide: Often preferred for chlorine evolution environments, such as brine solutions or industrial wastewater.

These coatings are applied through thermal decomposition, creating a tenacious, electrochemically active layer. Coating thickness, a critical specification, directly impacts anode lifespan and current output capabilities.

Ribbon dimensions vary considerably:

| Characteristic | Specification Range | Impact on Performance |

|---|---|---|

| Titanium Grade | ASTM B265 Grade 1 or 2 | Substrate integrity, mechanical strength. |

| Ribbon Width | 6.35 mm to 25.4 mm (0.25" to 1") | Current distribution, installation flexibility. |

| Ribbon Thickness | 0.6 mm to 1.5 mm (0.024" to 0.06") | Mechanical strength, cost. |

| MMO Coating Load | 5 g/m² to 20 g/m² (Iridium equivalent) | Anode lifespan, current output capability. |

| Current Density Rating | Up to 150 A/m² in certain conditions | Efficiency, suitability for environment. |

Selecting the correct ribbon size, coating type, and coating load is paramount for optimizing system performance and longevity. Our team at China Titanium Factory assists clients in specifying the ideal product for their unique needs, ensuring maximum asset protection.

Applications in Focus: Where Titanium Ribbon Anodes Excel in Corrosion Mitigation

The adaptability of titanium ribbon anodes makes them a go-to solution across a spectrum of industries. Their geometry allows for flexible installation, while their electrochemical properties deliver robust protection.

Pipeline Protection: Crucial for long-distance oil, gas, and water pipelines, especially those buried in varied soil conditions. Ribbon anodes can be laid parallel to the pipeline, providing uniform current distribution and preventing localized corrosion hotspots.

Reinforced Concrete Structures: Bridges, parking decks, buildings, and marine structures often suffer from rebar corrosion, causing spalling and structural compromise. Ribbon anodes, embedded within the concrete or applied to the surface, protect the steel rebar, extending the life of these vital assets.

Storage Tank Bottoms: Protecting the external bottom of above-ground storage tanks is a major challenge. Ribbon anodes, installed in a grid pattern beneath the tank, effectively mitigate soil-side corrosion, a common cause of leaks.

Marine Structures: Piers, jetties, offshore platforms, and sheet piling face aggressive saltwater environments. Titanium ribbon anodes are highly resistant to chloride attack and provide reliable protection for submerged and splash zone areas.

Water and Wastewater Treatment Plants: Corrosion is rampant in these facilities due to corrosive chemicals and constant moisture. Ribbon anodes offer a durable solution for tanks, clarifiers, and various metallic components.

Each application demands a tailored approach, considering factors like electrolyte resistivity, current requirements, and structural geometry. A blanket solution rarely cuts it; precision is key.

The 'TitanGuard™ Protocol': Our Proprietary 5-Phase Approach to Anode System Design and Deployment

Effective cathodic protection isn't just about good anodes; it's about a systematic, rigorous process. At China Titanium Factory, we've formalized our extensive experience into the TitanGuard™ Protocol. This unique 5-phase methodology ensures optimal design, flawless execution, and sustained protection for every project. It's our Golden Rule for corrosion mitigation: Understand the threat, design the defense, deploy with precision, verify performance, and maintain vigilance.

According to our analysis, haphazard installations lead to premature failures and wasted investments. The TitanGuard™ Protocol mitigates these risks by providing a structured framework:

Phase 1: Comprehensive Site Assessment & Data Acquisition:

Detailed investigation of the structure, environment (soil resistivity, water chemistry), existing corrosion damage, and historical data.

Identification of specific threats and cathodic protection requirements.

Phase 2: Tailored System Design & Anode Selection:

Engineering of the ICCP system, calculating current requirements, anode spacing, and rectifier specifications.

Precise selection of titanium ribbon anode type, dimensions, and MMO coating based on environmental conditions and desired lifespan.

Development of detailed schematics and material lists.

Phase 3: Precision Installation & Quality Control:

Execution of the installation plan by trained personnel.

Rigorous quality checks at every step: trenching, anode placement, cable connections, backfill, and rectifier hook-up.

Adherence to industry best practices and safety standards.

Phase 4: Commissioning & Performance Verification:

Initial energization of the system and thorough testing.

Measurement of structure-to-electrolyte potentials, current outputs, and system efficiency.

Adjustment of rectifier settings to achieve optimal protection levels, meeting NACE standards (e.g., criteria from NACE International).

Phase 5: Ongoing Monitoring & Maintenance:

Establishment of a routine monitoring schedule for potential readings and current output.

Regular inspections and proactive maintenance to ensure continuous system effectiveness.

Data analysis to identify trends and address potential issues before they escalate.

The TitanGuard™ Protocol ensures that every project benefits from a meticulously planned and executed cathodic protection strategy. This isn't guesswork; it's engineered reliability.

Precision Installation: A Step-by-Step Guide for Optimal Anode System Integration

Even the best anode material fails without proper installation. Precision is paramount. Here’s a streamlined approach to integrating titanium ribbon anodes:

Site Preparation

First, clear the area. Mark all underground utilities. Excavate trenches to the specified depth and width, ensuring they're free of sharp objects that could damage the anode or cable insulation.

Anode Placement

Lay the titanium ribbon anode in the trench. Maintain consistent spacing as per design specifications. For concrete applications, secure the ribbon directly to the rebar or within slots. For pipelines, ensure the ribbon runs parallel and at a uniform distance.

Electrical Connections

Connect header cables to the anode ribbon using approved methods, typically crimped and sealed connections, ensuring waterproof integrity. Use insulated copper cables for the header and lead wires. Proper insulation prevents stray current corrosion and ensures current flows where it's supposed to. All connections must be robust and corrosion-resistant.

Backfill Material

Apply a conductive backfill, usually coke breeze, around the anode ribbon. This material lowers the anode-to-earth resistance, ensuring efficient current discharge and protecting the anode from direct mechanical damage. Compact it well, but gently. Then, backfill the rest of the trench with native soil.

System Commissioning

After backfilling, connect the anode system to the DC rectifier. Perform initial tests to verify circuit continuity and measure potentials. Adjust the rectifier output to achieve the target protection criteria. This critical step ensures the system is functional and optimized from day one. Need hands-on support? Explore our CP installation services for expert deployment.

Sustaining Performance: Maintenance, Monitoring, and Troubleshooting for CP Systems

Installing a cathodic protection system is a significant investment; protecting that investment requires ongoing vigilance. A well-designed system with titanium ribbon anodes provides long-term protection, but only if regularly maintained and monitored. This isn't a "set it and forget it" scenario.

Routine Monitoring

Regular potential readings are critical. Use permanent test stations or portable reference electrodes to measure the structure-to-electrolyte potential. These readings tell you if the structure is sufficiently polarized. Rectifier output (voltage and current) should also be logged to ensure stable operation. Deviations from baseline values often signal an issue.

Preventive Maintenance

Inspect rectifiers, junction boxes, and cable connections regularly. Look for physical damage, corrosion, or loose connections. Clean ventilation ports on rectifiers. Check for signs of AC interference or stray current issues. Proactive maintenance prevents minor problems from becoming major system failures.

Troubleshooting Common Issues

If potential readings drop or current output is inconsistent, it's time to troubleshoot. Common culprits include:

Rectifier Failure: Check input power, fuses, and internal components.

Cable Damage: Buried cables can be cut or abraded. Use fault locators.

Anode Bed Resistance Increase: Can occur due to dry soil or depletion of backfill.

Interference: Nearby electrical systems or other CP systems can cause issues.

At China Titanium Factory, we recommend adhering to industry standards like those from ISO (International Organization for Standardization) for CP system maintenance. Consistent monitoring and timely intervention extend system lifespan and ensure continuous asset protection.

Real-World Success: Case Studies in Titanium Ribbon Anode Implementation

Seeing is believing. The theoretical advantages of titanium ribbon anodes translate directly into measurable, long-term success in the field. These aren't just components; they're solutions that save billions in avoided repairs and extend infrastructure lifespans.

Case Study 1: Municipal Water Pipeline Upgrade

A major metropolitan area faced escalating maintenance costs for its aging cast iron water pipeline network. Extensive external corrosion led to frequent leaks and service disruptions. Traditional sacrificial anodes proved insufficient due to varying soil resistivities. Implementing an ICCP system with titanium ribbon anodes along critical sections of the pipeline resulted in immediate polarization. Within six months, pipe-to-soil potentials reached protective levels across the entire treated segment. Leak rates plummeted by over 80% in the subsequent five years, proving the system's effectiveness and providing a substantial ROI.

Case Study 2: Concrete Bridge Deck Rehabilitation

A coastal highway bridge, exposed to de-icing salts and marine spray, showed severe rebar corrosion and concrete spalling. Conventional repairs offered only temporary relief. Engineers opted for an impressed current CP system using titanium ribbon anodes embedded in the concrete overlay. The anodes provided uniform current distribution to the steel reinforcement. Potential monitoring confirmed consistent protection, halting further corrosion. This extended the bridge’s service life by an estimated 25 years, deferring a full replacement project costing hundreds of millions. More examples of successful implementations are available in our case studies section.

Selecting Your Partner: Manufacturers, Industry Standards, and Procurement Best Practices

The success of your cathodic protection project hinges on the quality of your components and the expertise behind them. Don't cut corners when it comes to titanium ribbon anodes. Choosing a reputable manufacturer is paramount.

Manufacturer Credibility

Look for manufacturers with a proven track record, extensive experience in titanium fabrication and MMO coating technology, and a commitment to quality. A supplier should offer comprehensive technical support, from initial design consultation to post-sale assistance. At China Titanium Factory, our focus is on delivering anodes that exceed expectations, backed by rigorous testing and quality control.

Adherence to Industry Standards

Ensure your chosen supplier adheres to international standards for materials and manufacturing. This includes ASTM for titanium grades and NACE (now AMPP) guidelines for cathodic protection systems. Compliance with these standards guarantees product consistency, performance, and safety.

Procurement Best Practices

When procuring titanium ribbon anodes:

Request Detailed Specifications: Insist on clear documentation of titanium grade, MMO coating composition, thickness (loading), and dimensional tolerances.

Verify Certifications: Ask for material test reports and quality certifications.

Consider Lead Times: Plan your project carefully, accounting for manufacturing and shipping times for specialized anodes.

Evaluate Technical Support: A responsive technical team can be invaluable during design, installation, and troubleshooting.

Sustainable Corrosion Protection: The Environmental and Economic Benefits of Titanium Ribbon Anodes

Beyond immediate asset protection, titanium ribbon anodes contribute significantly to sustainability. This isn't just about delaying rust; it's about smart resource management and environmental stewardship.

Environmental Advantages

By preventing corrosion, these anodes directly reduce the need for premature replacement of infrastructure. This means less raw material extraction, reduced manufacturing energy consumption, and fewer waste products. Consider a leaking pipeline: a CP system prevents oil spills or chemical contamination, protecting ecosystems. Furthermore, the titanium and MMO materials themselves are stable and do not introduce harmful substances into the environment during operation.

Long-Term Economic Benefits

The economic case is compelling. While initial costs for an ICCP system might be higher than simpler alternatives, the long-term savings are immense:

Extended Asset Life: Doubling or tripling the lifespan of a pipeline or bridge defers massive capital expenditure for replacement.

Reduced Maintenance & Repair: Fewer leaks, less structural degradation, and fewer emergency repairs mean lower operational budgets.

Avoided Downtime: Keeping critical infrastructure operational prevents costly service interruptions and associated revenue losses.

Enhanced Safety: Preventing failures improves safety for workers and the public, avoiding potentially catastrophic incidents.

Investing in high-quality titanium ribbon anodes is an investment in both fiscal responsibility and environmental protection. It's a win-win.

Frequently Asked Questions About Titanium Ribbon Anodes

What is the expected lifespan of a titanium ribbon anode?

With proper design, installation, and monitoring, titanium ribbon anodes typically have an operational lifespan of 20 to 50 years, or even longer. The exact duration depends on the MMO coating thickness, current density, and the specific environmental conditions.

Are titanium ribbon anodes suitable for all types of soil?

Yes, they are highly versatile. Titanium ribbon anodes perform exceptionally well in a wide range of soil resistivities, from highly conductive to resistive soils, especially when paired with an appropriate conductive backfill. This adaptability is one of their key advantages over other anode types.

How do titanium ribbon anodes compare to sacrificial anodes?

Titanium ribbon anodes are used in impressed current cathodic protection (ICCP) systems, requiring an external power source. Sacrificial anodes (e.g., magnesium, zinc) generate current through their natural potential difference with the protected structure. Ribbon anodes offer higher current output, cover larger areas, and have significantly longer lifespans, making them ideal for large, critical, or high-resistivity applications where sacrificial anodes are impractical or insufficient.

Can titanium ribbon anodes be used in saltwater environments?

Absolutely. Their MMO coating is highly resistant to chloride attack, making them an excellent choice for marine and brackish water applications. They effectively protect submerged structures, splash zones, and reinforced concrete exposed to seawater.

What maintenance is required for a system using these anodes?

While the anodes themselves are highly durable, the entire ICCP system requires routine monitoring. This includes regular checks of rectifier output, periodic potential readings of the protected structure, and inspection of all electrical connections. Proactive maintenance ensures continuous, optimal performance.

Secure Your Assets. Prevent Corrosion.

Don't let corrosion compromise your critical infrastructure. Leverage the superior protection of titanium ribbon anodes, engineered for longevity and peak performance. With our expertise and the proven TitanGuard™ Protocol, your assets are safe.

Get a Quote Today