Unlocking Performance: Your Global Partner for Type 2 Titanium Anodizing

Critical components demand more than just raw material strength. They require surface integrity, enhanced durability, and consistent performance under extreme conditions. Without specialized surface treatments, even the finest titanium can succumb to wear, galling, and friction, compromising the entire assembly.

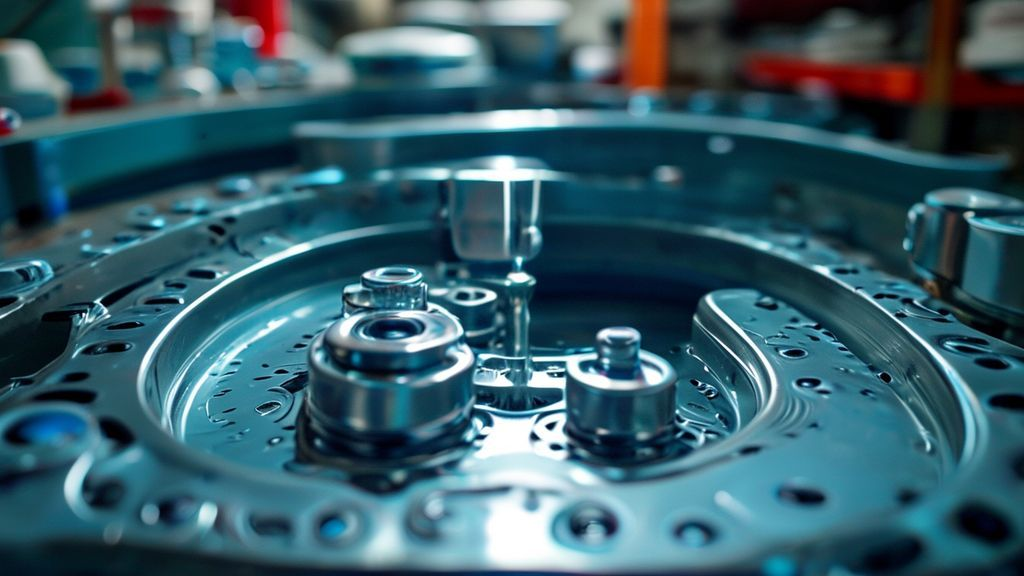

That's where China Titanium Factory steps in. We deliver world-class Type 2 Titanium Anodizing services, engineered to elevate your components' operational lifespan and reliability. Our process creates a lubricious, uniform oxide layer, making parts tougher, smoother, and more resilient. We provide the solution that keeps your high-stakes applications running like a well-oiled machine.

From aerospace to medical devices, our global reach and technical prowess ensure your components meet the most stringent specifications. We're not just a supplier; we're an extension of your engineering team, committed to pushing the boundaries of material performance.

Understanding Type 2 Titanium Anodizing: The Foundation of Durability

Type 2 Titanium Anodizing, often referred to as a "smooth" or "lubricious" anodize, is an electrolytic passivation process. It forms a thin, dense, and exceptionally hard oxide layer on the titanium surface. Unlike other anodizing types, Type 2 is specifically designed to minimize friction and prevent galling, a common issue in titanium-on-titanium contact.

This electrochemical conversion process alters the surface microstructure, integrating the oxide layer with the base metal. The result is a highly adherent, non-conductive, and biologically inert surface that significantly outperforms untreated titanium.

Definition: Type 2 Titanium Anodizing

Type 2 Titanium Anodizing is an electrochemical process defined by standards like AMS 2488. It creates a thin, non-porous, lubricious titanium oxide layer, primarily for enhancing wear resistance, preventing galling, and improving biocompatibility without significantly altering dimensional tolerances.

Key Benefits of Type 2 Anodizing for Critical Components

The advantages of Type 2 Anodizing are profound for components operating in demanding environments. This treatment isn't just a surface finish; it's a performance upgrade.

Superior Wear Resistance: The hard ceramic-like oxide layer drastically reduces abrasive wear, extending component life.

Exceptional Anti-Galling Properties: Prevents cold welding and material transfer between mating titanium surfaces, crucial for dynamic assemblies.

Enhanced Biocompatibility: The inert oxide layer makes components ideal for medical implants and instruments, meeting stringent biological safety requirements.

Improved Corrosion Resistance: Provides an additional barrier against chemical attack and oxidation.

Dimensional Stability: The thin, dense layer adds minimal thickness, making it suitable for precision-machined parts.

Non-Toxic and Environmentally Friendly: The process typically uses non-toxic electrolytes, aligning with modern sustainability goals.

Type 2 vs. Other Titanium Anodizing Methods: A Clear Comparison

While various titanium anodizing types exist, Type 2 holds a distinct niche. Understanding the differences is paramount for optimal material selection and application.

| Feature | Type 2 (AMS 2488) | Type 3 (Hard Anodize) | Color Anodizing (Type 1) |

|---|---|---|---|

| Primary Benefit | Anti-galling, wear resistance, biocompatibility | Extreme hardness, abrasion resistance | Aesthetics, color coding, mild corrosion protection |

| Layer Thickness | Thin (0.00002" - 0.00006") | Thick (up to 0.002") | Very thin (nanometers) |

| Surface Appearance | Slightly dull gray/green, lubricious feel | Dark gray to black, very hard | Vibrant colors (interference colors) |

| Key Standard | AMS 2488, ASTM F86 | No specific aerospace hard anodize for Ti | No specific standard |

| Typical Applications | Medical implants, aerospace fasteners, sliding components | Heavy wear parts (less common for Ti) | Decorative items, surgical instruments for identification |

Type 2 is the workhorse for friction reduction and biocompatibility. When the application demands minimal dimensional change, a non-galling surface, and biological inertness, Type 2 is the unequivocal choice. It’s a targeted solution for specific, high-performance needs.

Applications Across Industries: Where Type 2 Anodizing Excels

The unique properties conferred by Type 2 Titanium Anodizing make it indispensable across a spectrum of critical industries. Its ability to solve persistent problems like galling and wear is a game-changer for component integrity.

Medical Devices & Implants: Biocompatibility is paramount. Type 2 anodizing, meeting standards like ASTM F86, provides an inert, non-toxic surface for orthopedic implants, surgical instruments, and dental components, ensuring patient safety and long-term device function. ASTM F86 is a cornerstone specification here.

Aerospace & Defense: Components operating in harsh environments, subject to high stress and friction, benefit immensely. Fasteners, engine parts, landing gear components, and structural elements gain enhanced wear resistance and anti-galling properties, critical for reliability and safety. This aligns with custom titanium solutions in demanding sectors.

Automotive (High-Performance): In racing and high-performance vehicles, lightweight titanium components often face severe friction. Type 2 anodizing on connecting rods, valves, and suspension parts reduces wear and improves efficiency.

Industrial & Manufacturing: Precision tooling, bearings, and sliding mechanisms made from titanium require surfaces that resist wear and galling. Type 2 treatment ensures these components maintain their tight tolerances and operational fluidity over time.

Every industry pushing the envelope of performance recognizes the value of this specialized treatment. It's a testament to its effectiveness and broad applicability.

The Precision of Our Type 2 Titanium Anodizing Process

Achieving the precise, uniform oxide layer characteristic of Type 2 Anodizing demands meticulous control and expertise. Our process at China Titanium Factory is engineered for consistency and repeatability, guaranteeing peak performance for every component.

Our comprehensive workflow ensures optimal results:

Pre-Treatment & Cleaning: Components undergo rigorous cleaning to remove all contaminants, oils, and surface impurities. This includes alkaline cleaning, pickling, and deoxidizing, essential for proper adhesion and uniform coating.

Racking: Parts are carefully racked to ensure optimal current distribution and prevent contact marks, which could compromise the anodized layer.

Anodizing Bath: Components are immersed in a precisely controlled electrolyte bath. A specific voltage and current density are applied, forming the desired titanium oxide layer. Our process parameters are fine-tuned to meet AMS 2488 and other relevant specifications.

Rinsing & Drying: Post-anodizing, parts are thoroughly rinsed to remove residual chemicals, then carefully dried.

Quality Inspection: Every batch undergoes stringent quality checks, including visual inspection, thickness measurement, and adhesion testing, to verify compliance with all client and industry specifications.

This systematic approach leaves no stone unturned. We ensure that your components receive a Type 2 anodize that's not just compliant, but truly optimized for its intended function.

Adhering to Global Industry Standards and Certifications

In industries where failure is not an option, adherence to global standards is non-negotiable. Our Type 2 Titanium Anodizing services are built upon a foundation of strict compliance, offering you peace of mind and verifiable quality.

We consistently meet and exceed critical specifications, including:

AMS 2488: This Aerospace Material Specification outlines the requirements for "Anodic Treatment - Titanium and Titanium Alloys Solution pH 12.0 to 13.0." It's the gold standard for Type 2 anodizing in aerospace applications. For detailed information, refer to the SAE International AMS 2488D standard.

ASTM F86: "Standard Practice for Surface Preparation and Marking of Metallic Surgical Implants." This specification ensures that medical devices treated with Type 2 anodizing meet the rigorous demands for biocompatibility and surface integrity.

ISO 13485: As an ISO 13485 certified facility, our quality management system is specifically tailored for medical device manufacturing, guaranteeing consistent quality and regulatory compliance. This commitment to quality extends across all our certifications and standards.

Our commitment to these standards isn't just about ticking boxes. It's about engineering reliability into every component we treat, ensuring they perform flawlessly in their intended roles. When you choose China Titanium Factory, you're choosing a partner dedicated to unparalleled quality and compliance.

Why Partner With Us for Your Type 2 Titanium Anodizing Needs?

Choosing the right anodizing partner is pivotal for your project's success. China Titanium Factory offers a distinct advantage, blending deep technical expertise with a client-centric approach that truly sets us apart.

Unrivaled Expertise: Our team comprises seasoned metallurgists and process engineers. They live and breathe titanium, understanding its nuances and how to optimize surface treatments for specific applications.

Global Production Capacity: We operate state-of-the-art facilities with the capacity to handle projects of any scale, from prototype runs to high-volume production, serving clients across continents.

Precision & Consistency: Our advanced automated systems and rigorous quality controls ensure every component receives a uniform, high-quality Type 2 anodize, batch after batch.

Dedicated Technical Support: We don't just process parts; we partner with you. Our experts offer consultation on material selection, design optimization, and specification interpretation to ensure the best possible outcome.

Cost-Effectiveness Without Compromise: Leverage our efficient processes and supply chain for competitive pricing, all while maintaining the highest international quality standards.

We don't just meet expectations; we aim to blow them out of the water. When precision, reliability, and technical prowess matter, China Titanium Factory is your go-to global partner.

Interactive Tools & Resources for Your Project

Planning your Type 2 Titanium Anodizing project should be straightforward. To simplify your workflow, we offer a suite of resources and tools designed to provide transparency and assist in informed decision-making.

While specific interactive tools like a cost estimator or finish selector are under development, our technical team is readily available for direct consultation. Explore our Titanium Grades Guide to understand material compatibility, and reach out to our specialists who can provide project-specific insights and preliminary cost assessments.

Consider our website a living repository of knowledge. We frequently update our insights section with technical articles and best practices. Think of us as your digital toolbox for all things titanium.

Success Stories: Delivering Excellence in Type 2 Anodizing

The proof of our capability lies in the consistent success of our clients. We've tackled complex challenges across diverse industries, delivering Type 2 Anodizing solutions that redefine performance benchmarks.

Aerospace Actuator Components: A leading aerospace manufacturer faced severe galling in titanium actuator shafts. Our Type 2 anodizing process eliminated the issue, extending component life by 300% and reducing maintenance cycles significantly.

High-Volume Medical Implants: For a major medical device company, we scaled Type 2 anodizing for millions of orthopedic screws and plates, ensuring consistent biocompatibility and anti-galling properties, critical for patient safety and regulatory approval.

Precision Robotics Grippers: A robotics firm required titanium gripper components with extreme wear resistance and minimal friction. Our Type 2 anodize delivered the necessary lubricity and durability, enabling faster, more precise robotic movements.

These aren't just anecdotes. They're tangible examples of how our expertise translates into real-world operational advantages for our partners. We don't just coat parts; we engineer solutions.

Frequently Asked Questions About Type 2 Titanium Anodizing

What is Type 2 Titanium Anodizing and how does it work?

Type 2 Titanium Anodizing is an electrochemical process forming a thin, dense, lubricious titanium oxide layer on the surface of titanium alloys. It works by immersing the titanium part in an electrolyte bath and applying an electric current, which converts the surface metal into a protective oxide. This layer is integral to the substrate, offering superior adhesion and performance.

What are the primary benefits of Type 2 Anodizing over other surface treatments?

Its primary benefits include exceptional anti-galling properties, significantly enhanced wear resistance, and superior biocompatibility. Unlike many other surface treatments, Type 2 anodizing adds minimal dimensional change, making it ideal for precision components. It also offers improved corrosion resistance and is non-toxic.

Which titanium alloys are suitable for Type 2 Anodizing?

Most common titanium alloys are suitable, including commercially pure titanium (CP Ti Grades 1-4) and alpha-beta alloys like Ti-6Al-4V (Grade 5). The specific alloy can influence the precise characteristics of the anodic layer, but the process is highly effective across the board. Our experts can advise on the optimal treatment for your specific titanium grade.

How does China Titanium Factory ensure quality and compliance with international standards?

We maintain strict adherence to international standards such as AMS 2488, ASTM F86, and are an ISO 13485 certified facility. Our quality management system incorporates rigorous in-process controls, advanced testing, and comprehensive documentation for every project. This ensures full traceability and consistent quality that meets or exceeds global benchmarks.

What is the typical lead time for Type 2 Anodizing projects?

Lead times vary based on project complexity, part volume, and current production schedules. We pride ourselves on efficient turnaround times without sacrificing quality. For a precise estimate, we recommend contacting our sales team directly with your project specifications. We aim to be transparent and responsive from the first inquiry.

Ready to Enhance Your Components?

Don't let wear, galling, or biocompatibility concerns hold your innovations back. Partner with China Titanium Factory for precision Type 2 Titanium Anodizing that delivers unmatched performance and durability.

Get a tailored solution designed for your specific needs, backed by global expertise and unwavering quality.

Request Your Free Quote Today