Yes, our titanium anode products are specifically engineered and highly suitable for both water electrolysis (Green Hydrogen production) and the demanding chlor-alkali industry. We supply Dimensionally Stable Anodes (DSA) with specialized Mixed Metal Oxide (MMO) coatings tailored for the unique electrochemical environment of each application [1].

Chlor-Alkali:Anodes are optimized for Chlorine Evolution Reaction (CER), offering high current efficiency and excellent resistance to chlorine and brine corrosion.

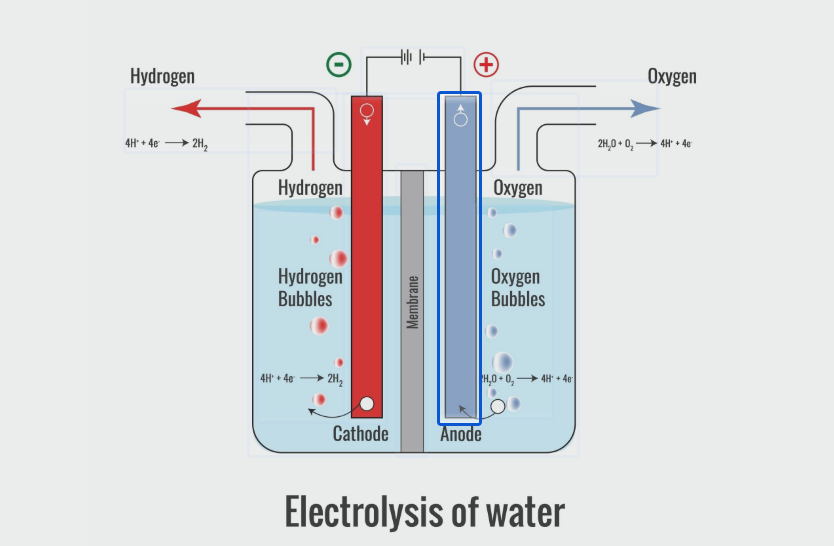

Water Electrolysis: Anodes are optimized for Oxygen Evolution Reaction (OER) or Hydrogen Evolution Reaction (HER), crucial for efficient hydrogen production.

The chlor-alkali industry (producing chlorine gas, caustic soda, and hydrogen) was one of the first major industrial adopters of DSA titanium anodes, replacing older graphite electrodes. Our anodes offer significant advantages:

High Current Efficiency: Reduces energy consumption in the electrolysis process.

Corrosion Resistance:The titanium substrate is highly resistant to the corrosive effects of wet chlorine and concentrated sodium chloride solutions [2].

Dimensional Stability: The anode maintains its shape, allowing for consistent cell gap and stable operating voltage over a long service life.

Typical Coating: Ruthenium-Iridium based MMO coatings are commonly used for the chlorine evolution reaction in brine electrolysis.

Titanium anodes are essential components in alkaline water electrolysis (AWE) and proton exchange membrane (PEM) electrolysis for producing Green Hydrogen. The primary requirements are high catalytic activity and long-term stability in the electrolyte.

PEM Electrolysis: Often uses platinum-plated titanium mesh or porous titanium transport layers (PTL) due to the highly acidic environment.

Alkaline Electrolysis: Uses specialized MMO coatings (often Iridium-based) to catalyze the oxygen evolution reaction (OER) at the anode [3].

| Industry | Electrochemical Reaction | Typical Anode Coating | Key Performance Benefit |

|---|---|---|---|

| Chlor-Alkali | Chlorine Evolution (CER) | Ruthenium-Iridium MMO | High current efficiency, low overpotential for Cl₂ production. |

| Water Electrolysis | Oxygen Evolution (OER) | Iridium-Tantalum MMO | High stability and activity in acidic/alkaline environments for O₂ production. |

Whether you are upgrading a chlor-alkali plant or developing a new hydrogen production facility, we provide custom-designed titanium anodes (mesh, plate, rod, tube) that maximize efficiency and service life. Our technical team can recommend the precise MMO formulation for your specific operating parameters.

Consult Our Specialists for Chlor-Alkali and Water Electrolysis Anode Solutions.