Titanium stands as one of the most remarkable metals in modern industry, renowned for its exceptional strength, lightweight characteristics, and outstanding resistance to corrosion. Among its many fascinating properties, titanium possesses the unique ability to transform into stunning color titanium through a sophisticated process known as anodizing. This process is crucial for various **titanium parts** used across industries. This comprehensive guide explores the intricate process of heat anodizing titanium, revealing how this advanced technique transforms ordinary titanium into vibrant, colorful materials that serve both aesthetic and functional purposes across numerous industries.

Anodizing represents a sophisticated electrochemical process that fundamentally alters the surface characteristics of metals to enhance both durability and visual appeal. While this process is most commonly associated with **aluminum and titanium** applications, titanium products can undergo this transformative procedure with equally impressive results. When titanium undergoes anodization, it develops a distinctive oxide layer, often referred to as a **natural oxide** layer, that creates beautiful color titanium variations, with the specific shade determined by the precise thickness of the oxide film formation. This is a key aspect of **titanium color anodizing**.

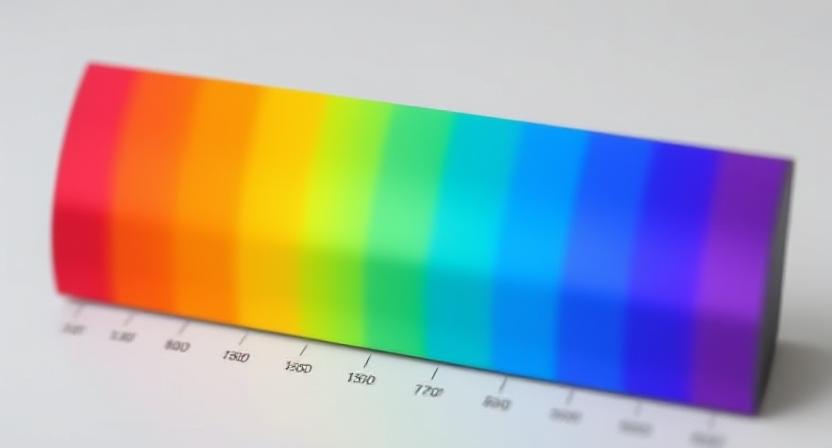

The spectacular colors that emerge on anodized titanium surfaces, unlike coatings on materials such as **stainless steel**, do not result from conventional dyes, paints, or surface coatings. Instead, these vibrant hues are produced through a complex optical phenomenon involving light interference within the oxide layer that forms on the metal's surface. When light encounters the anodized surface, it reflects simultaneously off both the oxide layer and the underlying metal substrate, creating what scientists term thin-film interference. This interference pattern generates the brilliant color titanium spectrum observed on properly anodized surfaces, making each piece unique in its visual characteristics. The precision in **anodizing work** is paramount to achieving the desired aesthetic.

Heat anodizing titanium represents a specialized methodology that utilizes precisely controlled thermal energy to modify the oxide layer formation on titanium surfaces, resulting in a comprehensive **range of color** variations for **color titanium**. Unlike traditional electrochemical anodizing processes that require electrical current application, heat anodizing depends entirely on meticulous temperature control and timing to achieve desired results.

Before any anodizing procedures can commence, the titanium surface must undergo thorough preparation. This critical preparatory phase involves comprehensive cleaning to remove oils, dirt, oxidation, and other contaminants that could adversely affect the anodizing process outcome. A meticulously cleaned surface ensures uniform oxide layer formation, resulting in consistent color titanium distribution across the entire treated area.

Once the titanium achieves optimal cleanliness, it undergoes controlled heat application. The specific temperature parameters and heating duration represent critical factors that directly determine the final color titanium characteristics of the anodized material. Generally, lower temperature applications produce warm gold and bronze hues, while elevated temperatures can generate cool blues, purples, and other vibrant colors. A detailed **color chart** can illustrate the spectrum achievable.

The applied heat initiates oxide layer formation on the titanium surface. As this layer increases in thickness with rising temperatures, the color titanium appearance shifts dramatically. This transformation occurs because the oxide layer thickness directly influences how light interference patterns interact with the surface, producing distinctly different color variations.

Heat anodizing titanium provides numerous significant advantages, establishing it as a preferred choice for diverse applications across multiple industries. Understanding the different **titanium anodizing type**s is crucial for selecting the optimal process.

The most immediately apparent benefit of anodized titanium lies in its exceptional aesthetic appeal. The vibrant color titanium variations achievable through precise anodizing make titanium an extraordinarily attractive choice for jewelry, luxury watches, and high-end decorative items. The ability to customize colors through exact temperature control enables unlimited design possibilities for creative applications.

The oxide layer formed during the anodizing process not only creates beautiful color titanium effects but also significantly enhances the material's overall durability. This protective layer substantially increases the metal's resistance to scratches, wear, and corrosion, making it exceptionally suitable for demanding environments that require superior durability characteristics, thereby **enhancing corrosion resistance**.

Titanium maintains its renowned biocompatibility characteristics, meaning it remains non-toxic and safe for medical applications. Anodized color titanium retains these essential biocompatibility properties, making it an excellent choice for medical implants and surgical instruments where both functionality and safety are paramount.

The unique properties of anodized color titanium make it exceptionally suitable for numerous applications across different industries and sectors.

Within the jewelry industry, anodized **color titanium** is highly prized for its vibrant color variations and remarkably lightweight characteristics. Rings, bracelets, necklaces, and other accessories crafted from anodized titanium are not only visually striking but also comfortable for extended wear, making them increasingly popular among discerning consumers.

The aerospace and automotive industries benefit tremendously from titanium's exceptional strength-to-weight ratio. Anodized **color titanium** components in these industries offer both aesthetic appeal and crucial functional advantages, including superior corrosion resistance and enhanced durability under extreme operating conditions.

As previously mentioned, the biocompatibility of anodized **color titanium** makes it a preferred material for medical device manufacturing. Surgical tools, implants, and dental components can all be manufactured from anodized titanium, successfully combining optimal functionality with essential safety requirements.

Professional **color titanium** production requires stringent quality control measures and advanced manufacturing capabilities. Leading manufacturers employ sophisticated welding, cutting, and CNC machining services to ensure consistent results and superior product quality across all applications.

Heat anodizing titanium represents a fascinating process that transforms strong, durable metal into colorful, versatile **color titanium** materials with exceptional properties. By understanding the scientific principles and technical procedures behind anodizing, one can fully appreciate the beauty and functionality that anodized titanium brings to various industries and applications.

Whether utilized in jewelry manufacturing, aerospace engineering, or medical device production, anodized **color titanium** continues to demonstrate its remarkable properties and vibrant appeal. The process of heat anodizing titanium not only enhances visual characteristics but also improves durability and versatility, making it an invaluable material for both aesthetic and functional applications.

This comprehensive understanding proves that titanium extends far beyond being merely a strong metal—it serves as a canvas for creativity and innovation, offering endless possibilities for **color titanium** applications across numerous industries. For those seeking high-quality titanium products and services, professional manufacturers provide the expertise and capabilities necessary to achieve optimal results in any application.