Choosing the right materials is critical for industrial manufacturing. Titanium coils offer a versatile and powerful solution, known for their strength and durability. This article explores the benefits of using titanium coils and how they can enhance industrial processes.

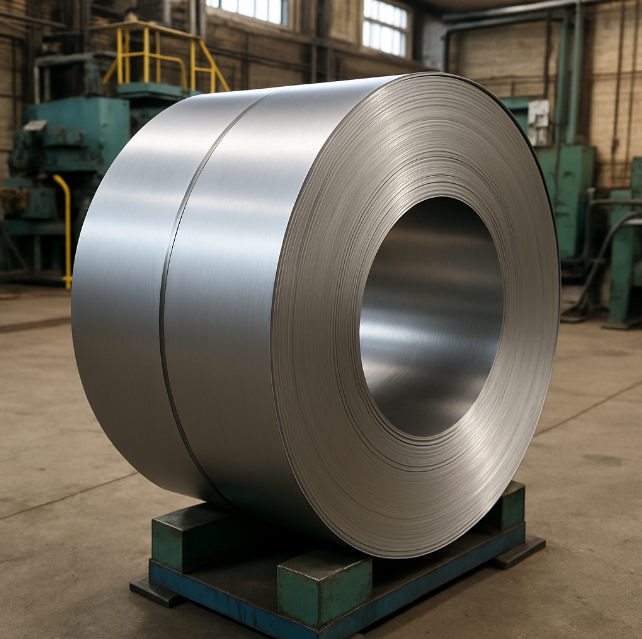

Titanium coils are made from titanium, a metal known for its exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These coils are used in a range of applications, from heat exchangers to medical devices, thanks to their unique properties. Titanium's lightweight nature coupled with its durability makes it an ideal choice for industries looking to optimize performance while minimizing material usage.

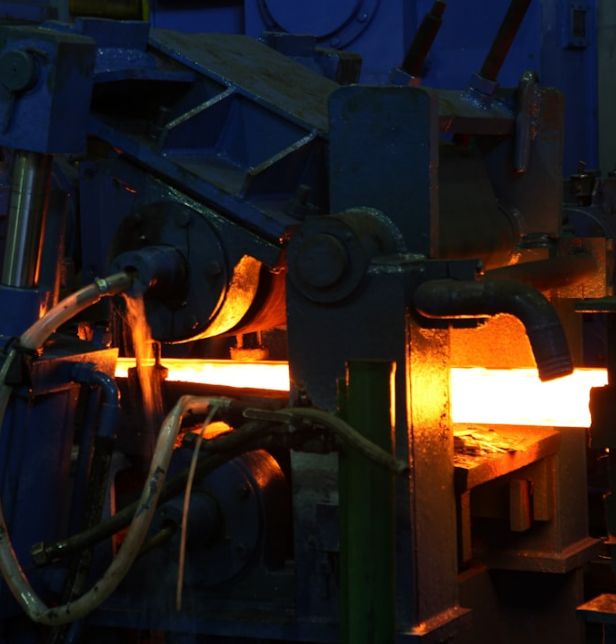

The production process of titanium coils involves precision engineering to ensure that they meet the stringent requirements of various industries. This involves the careful selection of titanium alloys, which are tailored to enhance specific properties such as flexibility or thermal conductivity. As a result, titanium coils not only meet but often exceed the performance of traditional materials used in similar applications.

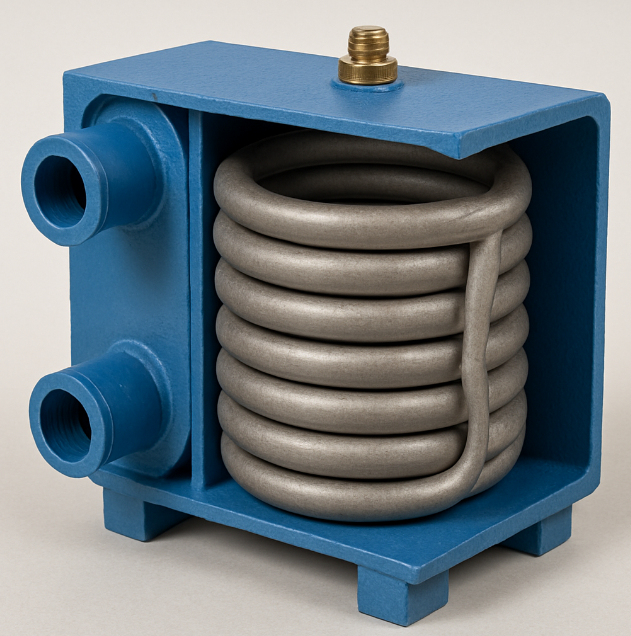

One of the most common uses of titanium coils is in heat exchangers. Titanium coil heat exchangers are highly efficient and durable, making them ideal for transferring heat in chemical processing, power generation, and HVAC systems. Their corrosion resistance ensures they can handle harsh environments without degrading, offering a long-lasting solution for heat management. This resistance is particularly crucial in chemical processing, where exposure to aggressive chemicals can quickly deteriorate other materials.

Moreover, titanium coil heat exchangers require less maintenance compared to their counterparts made from other metals. This translates to reduced downtime and lower operational costs, giving industries a competitive edge. The efficiency of titanium in transferring heat also contributes to energy savings, which is increasingly important in today's environmentally conscious market. The ability to maintain performance over a longer period without the need for frequent replacements makes titanium coils a cost-effective choice in the long term.

In addition to heat exchangers, titanium coils are widely used in chillers. A titanium coil chiller is perfect for cooling systems where reliability and efficiency are paramount. These coils maintain optimal temperatures in industrial processes, ensuring systems run smoothly and efficiently. The high thermal conductivity of titanium ensures that chillers operate at peak efficiency, conserving energy and reducing operational costs.

The robustness of titanium coils in chillers also means they can withstand fluctuating temperatures and pressures that would otherwise wear out less durable materials. This is especially important in industries where maintaining precise temperature control is critical, such as in food processing or pharmaceuticals. The ability of titanium coils to deliver consistent performance under varying conditions makes them indispensable in these sectors.

Titanium's resistance to corrosion is legendary. Unlike other metals that may rust or corrode when exposed to chemicals or saltwater, titanium remains unaffected. This makes titanium coils ideal for industries like marine, chemical processing, and oil and gas, where exposure to corrosive substances is common. The inherent corrosion resistance of titanium not only extends the lifespan of components but also ensures safety and reliability in critical applications.

This resistance also reduces the need for protective coatings or treatments, which can add to the cost and complexity of maintenance. In marine applications, for instance, titanium coils can withstand the harsh saltwater environment without the need for frequent replacements, making them a preferred choice for shipbuilding and offshore platforms. The longevity and reliability of titanium coils in such demanding environments highlight their superiority over traditional materials.

Titanium offers an impressive strength-to-weight ratio. This means you get the strength of steel but at a fraction of the weight. This property is particularly beneficial in applications where weight savings are crucial, such as in aerospace or automotive industries. The reduced weight of titanium coils contributes to improved fuel efficiency and performance, as lighter components require less energy to move.

In the aerospace industry, every kilogram saved translates to significant fuel savings, making titanium an invaluable material for aircraft construction. Similarly, in the automotive sector, lighter vehicles mean better fuel economy and lower emissions, aligning with the industry's push towards sustainability. The ability to maintain strength while reducing weight makes titanium coils an essential component in modern engineering solutions.

Titanium coils can withstand extreme temperatures, both hot and cold. This makes them suitable for a variety of applications, from high-temperature industrial processes to low-temperature cryogenic systems. The versatility of titanium in handling temperature variations ensures that it remains a reliable choice across different sectors.

In high-temperature applications, such as those found in the energy sector, titanium coils maintain their structural integrity and performance, reducing the risk of failure and ensuring continuous operation. In cryogenic systems, titanium's ability to withstand extremely low temperatures without becoming brittle ensures safety and reliability. This exceptional temperature tolerance expands the range of applications where titanium coils can be effectively utilized.

Titanium alloy coil springs are used in applications requiring a combination of strength, flexibility, and lightweight properties. They're common in the automotive and aerospace industries, where they contribute to improved fuel efficiency and performance. The unique properties of titanium allow these springs to absorb and dissipate energy effectively, enhancing the overall performance of vehicles and aircraft.

In the automotive industry, titanium coil springs are used to improve handling and ride quality, while also reducing the overall weight of the vehicle. In aerospace, they contribute to the structural integrity and performance of aircraft, enabling them to withstand the demanding conditions of flight. The use of titanium in coil springs is a testament to its versatility and performance advantages.

In the medical field, titanium coils are used to treat aneurysms. These coils help to block blood flow into the aneurysm, reducing the risk of rupture. Their biocompatibility ensures they can be safely used within the human body without causing adverse reactions. The use of titanium in medical applications underscores its reliability and safety, critical factors in healthcare.

Titanium's non-reactive nature makes it ideal for medical implants and devices, as it reduces the risk of inflammation or rejection by the body. The success of titanium coils in treating aneurysms has led to further exploration of its potential in other medical applications, such as orthopedic implants and dental devices. The ongoing research into titanium's medical uses continues to expand its role in improving patient outcomes.

Titanium wire and tubing are often used alongside coils in various industrial applications. These components offer the same benefits of strength, corrosion resistance, and temperature tolerance, making them versatile options for manufacturers. The seamless integration of titanium wire and tubing with coils enhances the overall performance and durability of industrial systems.

In industries such as aerospace and automotive, titanium tubing is used in exhaust systems and hydraulic lines, where its lightweight and strong properties are advantageous. Titanium wire is also used in electrical applications due to its excellent conductivity and durability. The combination of titanium wire, tubing, and coils provides comprehensive solutions for modern engineering challenges.

When selecting a titanium coil manufacturer, it's important to consider quality, reliability, and experience. A reputable manufacturer will provide high-quality titanium products that meet industry standards and offer the technical support needed to integrate these components into your operations effectively. The choice of manufacturer can significantly impact the performance and longevity of titanium components in your systems.

Quality Assurance: Ensure the manufacturer adheres to strict quality control processes to guarantee the performance and durability of titanium coils. A commitment to quality assurance reflects the manufacturer's dedication to delivering reliable products that meet or exceed customer expectations.

Technical Expertise: Look for manufacturers with a proven track record and expertise in producing titanium products. Experienced manufacturers are better equipped to offer guidance and support, helping you choose the right products for your specific needs.

Customer Support: Choose a supplier who offers excellent customer service and technical support to assist with any issues or questions. Responsive customer support can make a significant difference in ensuring the smooth integration and operation of titanium components in your systems.

As industries continue to evolve and demand more efficient and reliable materials, the use of titanium coils is expected to grow. Innovations in titanium manufacturing and applications are paving the way for even more advanced uses across various sectors. The ongoing development of new alloys and production techniques promises to enhance the performance and expand the applications of titanium in the future.

Titanium's durability and corrosion resistance mean that products made from this material have a longer lifespan, reducing waste and the need for frequent replacements. This contributes to more sustainable industrial practices and a reduction in environmental impact. The long-term benefits of using titanium include not only cost savings but also a smaller carbon footprint, aligning with global efforts to promote sustainability.

The recycling potential of titanium also adds to its environmental appeal. As industries move towards more circular economies, the ability to recycle and repurpose titanium components further enhances its value. The environmental benefits of titanium are increasingly being recognized, driving its adoption in various applications.

Research and development in titanium applications continue to expand the possibilities for this versatile metal. From advanced aerospace components to cutting-edge medical devices, the future of titanium is bright. Innovations in additive manufacturing and alloy development are opening new frontiers for titanium, making it a key material in the quest for technological advancement.

The exploration of titanium's potential in emerging fields such as renewable energy and nanotechnology highlights its versatility and adaptability. As new applications are discovered and existing ones are refined, titanium is set to play a crucial role in shaping the future of industry.

Titanium coils offer numerous benefits for industrial applications, from superior corrosion resistance to exceptional strength and temperature tolerance. Whether you're involved in chemical processing, aerospace, or the medical field, titanium coils can enhance your operations and provide a reliable solution for your needs. Their versatility and performance make them an invaluable asset in the pursuit of efficiency and innovation.

By choosing the right titanium coil manufacturer and staying informed about the latest advancements in titanium technology, you can ensure your business remains at the forefront of industry innovation. Embrace the power of titanium and unlock new possibilities for your industrial processes. The future of titanium is bright, and its potential to transform industries is only beginning to be realized.