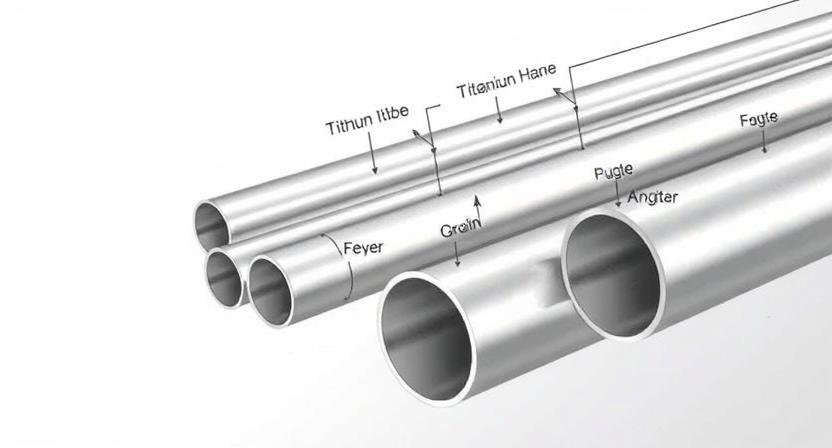

In demanding industrial applications, the exceptional properties of titanium tubing are indispensable. Specifically, for critical components like heat exchangers, the material’s inherent high strength combined with its remarkable light weight offers unparalleled performance. This makes titanium seamless tube a preferred choice across diverse sectors, from aerospace and medical to chemical processing, where corrosion resistance and durability are paramount. Ensuring quality and performance in these applications hinges on selecting a reliable supplier.

Before we dive into the top suppliers, it’s essential to understand what makes titanium tubes so desirable. Titanium tubes are renowned for their high strength, lightweight nature, and exceptional resistance to corrosion, making them an ideal choice for various demanding applications. Their ability to withstand harsh environments and resist chemical degradation has made them the material of choice for industries such as aerospace, marine, and industrial processes. These industries often operate in extreme conditions where other materials might fail, thus relying heavily on the superior properties of titanium.

Titanium tubes come in a variety of grades, each meticulously engineered with distinct properties to meet specific industrial demands. These grades are broadly categorized into Commercially Pure (CP) titanium and titanium alloys, offering a spectrum of characteristics from high ductility and corrosion resistance to exceptional strength and elevated temperature performance. Understanding these distinctions is crucial for selecting the optimal material for any given application.

Commercially Pure titanium is unalloyed, with its grades (Grades 1-4) differentiated primarily by their oxygen and iron content, which influences their strength and ductility. As the grade number increases, so does the strength, while ductility generally decreases.

Grade 1 (Gr1): This is the softest and most ductile of the CP grades, offering superior formability and excellent corrosion resistance. Its high ductility makes it ideal for cold forming operations. Applications include chemical processing equipment, desalination plants, and medical devices where high corrosion resistance and ease of fabrication are paramount.

Grade 2 (Gr2): Often referred to as the “workhorse” of the titanium industry, Grade 2 offers a balance of strength, ductility, and excellent corrosion resistance. It is the most commonly used CP grade for industrial applications, including power generation, chemical processing, and marine components, due to its versatility and ease of fabrication.

Grade 3 (Gr3): Stronger than Grade 2 with slightly less ductility, Grade 3 is used in applications requiring moderate strength and good corrosion resistance. It finds use in aerospace and industrial applications where higher mechanical properties are needed than Grade 2.

Grade 4 (Gr4): The strongest of the CP grades, Grade 4 offers excellent strength and good formability, though less ductile than the lower CP grades. It is often used in airframe components, surgical implants, and heat exchanger tubing where maximum strength from a CP grade is required.

Titanium alloys are created by adding other elements (such as aluminum, vanadium, molybdenum, and palladium) to titanium to enhance specific properties like strength, heat resistance, or corrosion resistance.

Grade 5 (Ti-6Al-4V): Also known as Ti 6Al-4V, this is the most widely used titanium alloy, accounting for over 50% of all titanium usage. It is a two-phase alpha-beta alloy renowned for its exceptional high strength, light weight, and excellent fracture toughness. Grade 5 maintains its strength at elevated temperatures and offers good corrosion resistance. Its primary applications are in aerospace (aircraft structures, engine components), medical implants, and high-performance automotive parts.

Grade 7 (Ti-0.2Pd): This grade is commercially pure titanium with a small addition of palladium, which significantly enhances its corrosion resistance, particularly in reducing acid environments. Grade 7 is often chosen for chemical processing equipment and other highly corrosive applications where Grade 2 might not suffice.

Grade 9 (Ti-3Al-2.5V): Known as “half-6-4,” Grade 9 is a medium-strength alpha-beta alloy that offers good cold formability and weldability, making it suitable for seamless tubing applications. It provides a good balance of strength and ductility, finding use in aerospace hydraulic systems, sports equipment, and bicycle frames.

Grade 12 (Ti-0.3Mo-0.8Ni): This alloyed grade offers enhanced strength and resistance to high temperatures, often used in chemical and marine applications. Gr12’s ability to perform in high-temperature environments makes it particularly valuable in chemical processing and power generation. Its superior strength also ensures longevity in demanding marine conditions.

To summarize the key characteristics and applications of these prominent titanium grades, refer to the table below:

| Grade | Type | Key Properties | Common Applications |

|---|---|---|---|

| Gr1 | CP | Softest, most ductile, excellent corrosion resistance | Chemical processing, desalination, medical devices |

| Gr2 | CP | “Workhorse” grade, good balance of strength, ductility, corrosion resistance | Power generation, chemical processing, marine components |

| Gr3 | CP | Moderate strength, good corrosion resistance | Aerospace, industrial applications |

| Gr4 | CP | Strongest CP grade, good formability | Airframe components, surgical implants, heat exchanger tubing |

| Gr5 | Alloy | Highest strength, light weight, excellent fracture toughness, good high-temperature strength | Aerospace (structures, engines), medical implants, high-performance automotive |

| Gr7 | Alloy | Enhanced corrosion resistance (especially in reducing acids) due to Palladium | Chemical processing equipment, highly corrosive environments |

| Gr9 | Alloy | Medium strength, good cold formability and weldability | Aerospace hydraulic systems, sports equipment, bicycle frames |

| Gr12 | Alloy | Enhanced strength, high-temperature resistance | Chemical processing, marine applications, power generation |

China Titanium Factory As a leading global supplier and manufacturer of high-quality titanium products, China Titanium Factory offers a full range of titanium materials and customized solutions. With advanced manufacturing processes and stringent quality control, their products are rigorously tested to ISO 9001:2015, ISO 13485, CE, and SGS standards. They provide a diverse portfolio including mill products, pipes, fittings, fasteners, and specialty anodes, catering to industries like aerospace, medical, chemical processing, and marine applications. Known for their efficient production, fast lead times, and customer-centric service, China Titanium Factory is committed to delivering superior quality and tailored solutions.

Baoji Titanium Industry Co., Ltd. Located in China’s “Titanium Valley,” Baoji Titanium Industry Co., Ltd. is a leading name among titanium tube manufacturers. They offer a wide range of products, including Gr1 and Gr12 titanium tubes, and are known for their adherence to ASTM B862 standards. Their commitment to quality and innovation has earned them a strong reputation in the industry, making them a preferred choice for companies looking for reliable titanium solutions. Additionally, their strategic location in a hub of titanium production ensures access to the latest technological advancements and a steady supply of high-quality materials.

Titanium Industries, Inc. As a global leader in specialty metals, Titanium Industries, Inc. provides high-quality titanium tubing solutions. They are recognized for their thick wall titanium tubes, which are essential in high-pressure applications. Their products are widely used in industries that demand robust materials, such as oil and gas exploration and aerospace engineering. With a focus on customer satisfaction, Titanium Industries, Inc. offers tailored solutions to meet specific industry requirements, ensuring that their clients receive products that are both reliable and efficient.

VSMPO-AVISMA VSMPO-AVISMA is the world’s largest titanium supplier, with a comprehensive range of products including pipes and tubes. Their extensive network and commitment to quality make them a top choice for industries worldwide. By leveraging their global presence, they offer unparalleled access to titanium products, ensuring that clients receive timely and efficient service. Their investment in state-of-the-art technology and sustainable practices further cements their position as a leader in the titanium industry, providing innovative solutions that cater to modern industrial challenges.

RTI International Metals (now part of Alcoa) RTI International Metals, now part of Alcoa, specializes in titanium products with a focus on innovation and sustainability. They offer a variety of titanium tube options tailored to meet specific industrial needs. Their dedication to research and development has resulted in cutting-edge products that push the boundaries of what’s possible with titanium. As part of Alcoa, they benefit from a wealth of resources and expertise, allowing them to continue delivering high-quality products that meet the rigorous demands of industries such as aerospace, defense, and medical technology.

Western Superconducting Technologies Co., Ltd. Another titan in the titanium industry, Western Superconducting Technologies Co., Ltd. is based in China and offers a diverse range of titanium tubes. They are particularly known for their expertise in manufacturing Gr12 titanium tubes. Their focus on quality and precision has made them a trusted supplier for industries that require materials capable of withstanding extreme conditions. By continuously innovating and expanding their product offerings, they remain at the forefront of the titanium market, providing solutions that cater to the evolving needs of their clients.

Quality Assurance and Certifications All the suppliers listed are known for their rigorous quality assurance processes, ensuring that each product meets or exceeds industry standards. Whether you need ASTM B862 compliant tubes or specific custom solutions, these manufacturers provide reliable quality. Their commitment to excellence is evident in their adherence to international standards and meticulous attention to detail, resulting in products that deliver consistent performance.

Global Reach and Logistics With facilities and partnerships around the world, these suppliers can cater to international markets. This global presence ensures that you receive timely delivery and support, no matter where your operations are located. By leveraging their extensive networks, these suppliers offer seamless service and logistical support, ensuring that your projects proceed without unnecessary delays or complications.

Innovation and Customization Staying ahead in the titanium market requires continuous innovation. These suppliers invest in research and development to offer new solutions and customizable options. Whether it’s developing new grades or enhancing existing ones, they are at the forefront of innovation. Their ability to adapt to changing market demands and technological advancements ensures that they remain competitive and capable of meeting the unique needs of their clients.

Customer Service and Support Exceptional customer service is a hallmark of these top suppliers. From initial inquiry to post-delivery support, they ensure a seamless experience, addressing any concerns and providing expert guidance. Their dedication to customer satisfaction is evident in their responsive communication and willingness to collaborate closely with clients, ensuring that their products meet or exceed expectations.

Product Range: Ensure the supplier offers the specific grades and types of titanium tubes you need. A comprehensive product range indicates the supplier’s capability to handle diverse requirements and provide tailored solutions.

Certifications: Check for industry certifications and compliance with international standards. Certifications serve as a testament to the supplier’s commitment to quality and adherence to recognized industry practices.

Experience and Reputation: Look for suppliers with a proven track record and positive customer feedback. An established reputation in the industry often correlates with reliability and expertise.

Technical Support: Opt for suppliers that offer technical support and customization options. Access to knowledgeable technical staff can be invaluable in addressing specific project challenges and ensuring optimal product performance.

In 2025, the demand for high-quality titanium tubes continues to grow, driven by advancements in technology and industrial needs. By choosing a reputable supplier, you ensure that your operations benefit from the best materials available. Whether you’re looking for thick wall titanium tubes or specific grades like Gr1 and Gr12, the suppliers listed here are equipped to meet your requirements with excellence.

As you navigate the landscape of titanium tube suppliers, remember to prioritize quality, service, and innovation. With the right partner, your projects can achieve new heights of success. By investing in a trusted supplier, you not only secure superior materials but also gain a reliable partner dedicated to supporting your industrial ambitions and contributing to your long-term success.