Welding titanium is a skill that opens doors to many advanced industries, from aerospace to medical. While it can be tricky, understanding the right techniques makes it much easier to achieve strong, high-quality welds. Titanium is highly valued for its incredible strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. This guide will walk you through the key steps and considerations for welding titanium successfully, helping you get the best results.

Titanium is a unique metal. It's as strong as steel but much lighter, making it perfect for situations where weight matters. It also resists corrosion better than most metals, ensuring things last a long time, even in harsh conditions. Plus, because it's biocompatible, it's safe for use in medical implants. Knowing these qualities helps us choose the right uses and welding methods for titanium.

Titanium is often mixed with other metals to make it even better. Here are some common types:

Grade 2 Titanium: This is pure titanium, known for being very resistant to corrosion and easy to shape. It's often used in chemical plants and marine settings because it can handle tough, corrosive elements.

Grade 5 Titanium (Ti-6Al-4V): This is the most popular alloy. It offers a great mix of strength, corrosion resistance, and weldability. You'll find it a lot in aerospace and automotive parts because it performs so well.

Grade 23 Titanium (Ti-6Al-4V ELI): This is a special version of Grade 5 with very low impurities, used for medical implants due to its biocompatibility and improved toughness, which is great for surgical tools.

Choosing the right titanium alloy is very important for good welding. Think about what you need the final product to do, like how strong it needs to be, how well it resists rust, and its weight. Each alloy has its own features that make it suitable for different projects. Working with material experts can help you pick the best alloy for top performance and durability.

Before you start welding titanium, proper preparation is crucial. This step helps prevent contamination and ensures your weld is strong and clean.

Titanium must be super clean before welding. Even tiny bits of oil, grease, or fingerprints can cause problems in the weld. Use a special non-chlorinated cleaner and a clean, lint-free cloth to wipe the surface. Avoid rough cleaning methods like sandblasting, as they can push particles into the titanium.

Keeping the surface spotless is vital for titanium welding. Any dirt can lead to issues like porosity or cracks, making the weld weak. Always check and clean carefully to keep the welding area perfect. This effort leads to stronger, more reliable welds.

Make sure to use the right cleaning solvent to avoid adding new dirt. Non-chlorinated solvents are best because they don't leave residue. Don't use household cleaners that might have oils. Test the cleaner on a small spot first to make sure it works well with the titanium.

Cross-contamination happens if titanium touches other metals or dirty tools. It's best to have specific tools and a dedicated workspace just for titanium projects. Regularly clean your equipment to stop unwanted transfer of contaminants. This keeps the titanium pure and the weld quality high.

Titanium reacts easily when it gets hot. To stop contamination, you need a clean and controlled workspace. This means having good ventilation and keeping titanium away from other metals. A dedicated workspace helps prevent cross-contamination and ensures consistent results. Use air filters to reduce airborne particles and make sure the area is well-ventilated to remove fumes, making the process safer and improving weld quality.

TIG (Tungsten Inert Gas) welding is the most common and recommended method for titanium. It gives you very precise control, which is essential for working with this metal.

TIG welding offers unmatched control and accuracy. Welders can precisely manage the heat and filler material, leading to clean, defect-free welds. This is especially good for thin titanium parts where precision is critical. Understanding TIG welding's benefits helps you choose the right projects for this method.

To master TIG welding, you need to understand how much heat to use, how fast to move, and how to add filler material. Practice is key to making perfect welds. Get familiar with the equipment settings and techniques specific to titanium to get the best welding results.

Even with its advantages, TIG welding titanium has challenges, like keeping the heat steady and preventing contamination. Knowing these challenges helps welders take steps like using enough shielding gas and controlling the welding environment. Dealing with these issues improves the chances of making high-quality welds.

Your titanium TIG welding rods must match the alloy you're welding. For example, Grade 2 titanium rods work for pure titanium, while Grade 5 rods are for Ti-6Al-4V alloys. Always make sure the rods are clean.

Using matching welding rods is vital for strong welds. If the rods don't match, you could end up with weak joints. Check with experts or material specifications to ensure your rods match the alloy's properties. This ensures the weld's strength and longevity.

Keep your welding rods clean too. Store them in a clean place and handle them with clean gloves to avoid adding impurities. Checking and cleaning rods before use helps prevent defects and ensures high-quality welds.

The size of the welding rod affects how deep the weld goes and its overall quality. Pick a rod size that fits the thickness of the titanium you're welding. Thinner rods give more precise control, while thicker ones provide more filler. Knowing the application and material thickness helps you choose the right rod size.

When setting up your TIG welder for titanium, remember these points:

Use Pure Argon or Helium as Shielding Gas: Titanium needs a high-quality shielding gas to protect it from contamination. Pure argon is common, but helium can be used for thicker materials to get deeper penetration.

Select the Right Tungsten Electrode: Use a 2% thoriated or 2% ceriated tungsten electrode for the best results. These electrodes offer good arc starting and resist contamination.

Control Heat Input: Too much heat can cause weld defects. Use a low amperage setting to control the heat and prevent overheating. Pulsed current techniques can help manage heat more effectively.

Shielding gas is critical for stopping oxidation and contamination. Pure argon is great and easy to find. For thicker materials, helium can help with deeper penetration. Understanding shielding gases helps you pick the right one for your project.

The tungsten electrode is important for a stable arc and good weld quality. Thoriated and ceriated electrodes start arcs well and resist contamination. Keep your electrode sharp and maintained for best performance and precise welds.

Controlling heat input prevents overheating and warping. Pulsed current helps manage heat better, giving you more control over the weld pool and reducing defects.

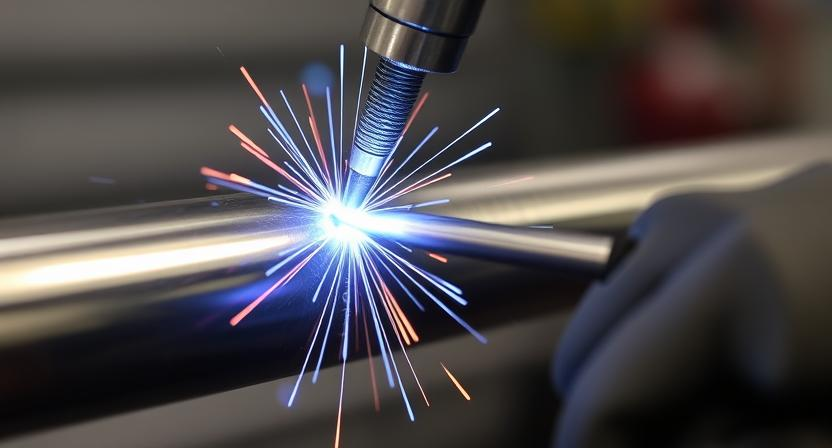

While TIG is preferred, other methods like MIG welding (GMAW), Laser welding, Electron Beam welding, and Friction welding can also be used for titanium. Laser welding, for example, offers high precision and minimal heat-affected zones, making it useful for thin materials and complex designs. However, these methods often require expensive equipment and specialized training.

After welding titanium, it's important to check and treat the welds to ensure they are good and will last.

Look for problems like porosity (small holes), cracks, or discoloration. Discoloration can mean contamination or not enough shielding gas during welding.

Image Placeholder: Titanium Weld Color Chart

Regular weld inspections are vital for quality and safety. Finding problems early means you can fix them before they cause bigger issues. Use visual checks and non-destructive tests to see how good the weld is. Common problems include porosity, cracking, and incomplete fusion. Knowing why these happen helps you prevent them.

Advanced inspection methods, like ultrasonic testing and radiography, can show hidden defects. These methods help ensure the reliability and safety of welded structures.

Some titanium alloys might need heat treatment after welding to relieve stress and improve their strength. Check the material specifications to see if this is needed for your alloy.

Heat treatment can make the weld stronger and more stable. It reduces internal stress and improves how well the part resists fatigue, making it last longer. Knowing these benefits helps you decide if heat treatment is necessary for your project.

Different titanium alloys need different heat treatment processes. Consult material specifications and metallurgists to find the right method. This ensures the weld gets the desired strength and performance.

Accurate monitoring of the heat treatment process is crucial. Use precise temperature controls and timing for consistent results. Document the process for future reference and quality assurance.

To make sure your titanium welding goes well, keep these tips in mind:

Always wear proper protective gear, including gloves, goggles, and a welding helmet. Safety is extremely important in welding, as heat, light, and fumes can be dangerous. Following safety rules protects you and those around you.

Personal Protective Equipment (PPE) is essential for protecting welders from burns, eye damage, and breathing in harmful fumes. Make sure all your protective gear meets industry standards and is checked regularly for wear. Proper use of PPE reduces accidents and makes the workplace safer.

Make sure the shielding gas covers the weld area continuously, both during and after welding, until the metal cools below 800°F. Consistent gas coverage is crucial to prevent oxidation and contamination. Using the best practices for gas flow improves weld quality.

Shielding gas protects the weld pool from air contamination, which is vital for keeping the weld strong and free of defects. Understand the properties and flow needs of your chosen shielding gas to make it most effective.

Be ready to fix common shielding gas problems, like leaks or not enough coverage. Regularly check gas lines and connections to ensure proper flow. Fixing these issues quickly ensures the weld area is always protected.

Adjust gas flow rates to balance good coverage with cost. Too much flow can cause turbulence and contamination, while too little might not protect enough. Experiment to find the best flow rate for your specific welding job.

Use the least amount of heat needed to make the weld. This lowers the risk of contamination and distortion. Controlling heat is key to keeping the weld strong and looking good.

Use techniques like pulsed welding and lower amperage to control heat effectively. These methods allow precise control over the weld pool, reducing defects. Understanding and using these techniques improves weld quality.

Getting the right balance between heat and weld quality takes practice. Watch the weld pool and adjust settings as needed. Consistent practice leads to better welds over time.

Watch out for signs of heat-related problems, like warping or too much discoloration. Make adjustments, such as changing travel speed or amperage, to fix these issues. Proactively managing heat helps prevent defects and makes welds more consistent.

Moisture can cause contamination, so it's best not to weld in humid places. Humidity can put hydrogen into the weld, leading to problems like porosity and cracking. Taking steps to control the environment improves weld quality.

Humidity affects welding by adding moisture to the weld pool, which can cause hydrogen embrittlement and other defects. Knowing how humidity impacts welding helps you take steps to reduce its effects.

Use things like dehumidifiers or climate-controlled workspaces to manage the welding environment. Check humidity levels and adjust conditions as needed for ideal welding. This proactive approach minimizes risks and ensures better weld quality.

Welding titanium requires careful attention to detail, especially regarding cleanliness, shielding, and heat control. By following these essential techniques and tips, you can overcome the challenges and achieve high-quality, durable titanium welds for various demanding applications. Remember, practice and patience are key to mastering this specialized welding process.