Medical grade titanium refers to specific pure titanium grades that meet strict high quality standards for medical applications. This metal is known for its impressive high strength, excellent strength to weight ratio, and superior corrosion resistant properties. These characteristics make it highly suitable for creating medical implant devices that need to perform reliably within the rigorous conditions of the human body. The standards for medical grade materials ensure that the grade titanium maintains its integrity and performance over time, which is essential for patient safety and comfort. It is widely used in various medical device manufacturing processes for implants, including orthopedic implants, dental implants, and bone fixation devices, highlighting its versatility and reliability in the medical industry.

Titanium stands out due to its exceptional strength to weight ratio. It is as strong as some steels but is nearly 45% lighter. This makes it ideal for titanium implant devices as it does not add unnecessary weight to the body, which is crucial for patient mobility and comfort post-surgery. Moreover, titanium is known for its exceptional corrosion resistant properties, which is crucial for implants that will remain in the human body for many years. This resistance is due to a protective oxide layer that forms naturally on its surface, shielding the metal from the corrosive effects of bodily fluids.

The metal's unique properties extend beyond just high strength and corrosion resistance. Titanium's ability to withstand extreme temperatures and its non-reactive nature make it a stable choice for medical implant devices. This stability ensures that titanium implants do not degrade or cause complications over time, providing a reliable solution for long-term medical applications. Additionally, titanium's aesthetic properties, such as its smooth and non-porous surface, can help in reducing bacterial adhesion, further minimizing infection risks.

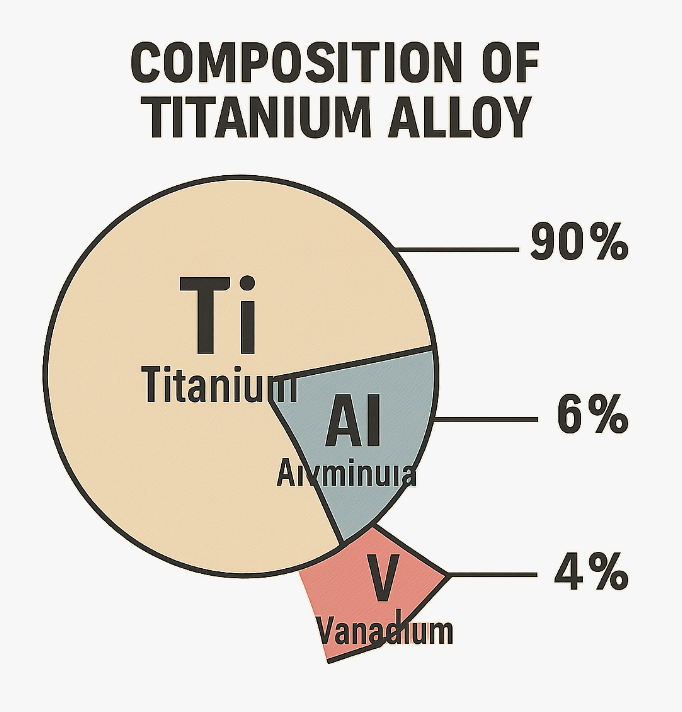

In the medical industry, commercially pure titanium is often combined with other elements to form titanium alloys. These alloys enhance certain properties, such as strength and durability, making them even more suitable for medical implants. By altering the composition of titanium alloys, manufacturers can tailor the material to meet the specific demands of different medical applications. Commonly used titanium alloys include Ti-6Al-4V, known for their superior performance in dynamic environments.

Titanium alloys offer additional benefits like improved fatigue resistance, which is critical for medical implant devices that undergo repeated stress, such as those in the spine or load-bearing joints. The adaptability of titanium alloys means they can be used in a wide range of medical devices manufacturing beyond just implants, including surgical instruments and diagnostic equipment. This versatility not only enhances the functionality of medical devices but also supports ongoing innovations in the design and development of new medical technologies.

One of the primary reasons medical grade titanium is favored in medical implants is its biocompatibility. This means that grade titanium is not harmful to living tissues and is unlikely to cause an adverse reaction when implanted in the human body. The human body accepts titanium implants very well, which reduces the risk of infection and rejection. This biocompatibility is attributed to titanium's ability to integrate with bone and tissue, a process known as osseointegration, which is critical for the stability and longevity of titanium implant devices.

The successful integration of grade titanium with human tissue also means that patients experience less post-operative inflammation and quicker healing times. This can significantly enhance patient recovery and reduce the duration of hospital stays, ultimately improving the overall healthcare experience. Furthermore, the predictability of titanium's interaction with the body allows surgeons to anticipate outcomes more accurately, facilitating better pre-surgical planning and patient education.

Titanium's durability is another significant advantage. Medical implant devices made from grade titanium are designed to last for many years, often decades. This is especially important for patients who undergo major surgeries like hip or knee replacements, where the titanium implant needs to withstand regular use without degrading. The longevity of titanium implants can greatly enhance a patient's quality of life by reducing the need for revision surgeries, which are not only costly but also involve additional recovery time and potential complications.

Moreover, the long-lasting nature of titanium implants means that patients can maintain an active lifestyle without the fear of implant failure. This durability is particularly beneficial for younger patients who require implants, as it ensures that the implants will serve them well throughout their lives. The reliability of grade titanium in providing enduring solutions makes it a preferred choice for both patients and healthcare providers aiming for the best possible long-term outcomes.

Titanium's corrosion resistant properties are vital for its use in the human body. The environment inside the body can be harsh for metals due to the presence of bodily fluids. However, grade titanium forms a natural oxide layer on its surface that protects it from corrosion, ensuring that the medical implant remains intact and functional over time. This corrosion resistance not only prolongs the life of the implant but also prevents the release of potentially harmful metal ions into the body, safeguarding patient health.

The ability of grade titanium to resist corrosion also means that it maintains its structural integrity over the years, which is crucial for the functionality of medical implants. This property is particularly important for implants that are exposed to constant movement and stress, such as those used in orthopedic implants and dental implants. By preventing corrosion, titanium implant devices help ensure that implants can perform their intended functions without interruption, providing consistent support and enhancing patient outcomes.

In orthopedics, medical grade titanium is used extensively for joint replacements and bone fractures. Its lightweight nature and high strength help create orthopedic implants that are comfortable for patients while providing the necessary support for healing and movement. The use of titanium implant devices in orthopedic implants has revolutionized the treatment of musculoskeletal disorders, offering solutions that are both effective and minimally invasive. This is particularly beneficial for elderly patients or those with compromised bone health, as titanium's properties support better integration and reduced recovery times.

The versatility of grade titanium in orthopedic implants extends to its use in spinal fusion surgeries, where its high strength and biocompatibility are critical for successful outcomes. Titanium implant plates, rods, and screws are commonly used to stabilize the spine and promote bone growth, providing patients with improved mobility and quality of life. The advancements in titanium-based orthopedic implants continue to evolve, offering new opportunities for addressing complex bone and joint conditions with precision and care.

Medical grade titanium is the material of choice for dental implants due to its ability to fuse with bone, a process known as osseointegration. This property ensures that dental implants remain securely in place and function like natural teeth. The success of titanium implant devices in dental implants has transformed the field of dentistry, providing patients with durable and aesthetically pleasing solutions for tooth replacement. The stability offered by titanium dental implants allows patients to enjoy a wide range of foods and maintain oral health without the limitations of traditional dentures.

Beyond its high strength and integration capabilities, grade titanium's corrosion resistant properties and resistance to wear make it ideal for the oral environment, where it is exposed to various forces and chemical interactions. This durability ensures that titanium dental implants can withstand the rigors of daily use, offering patients a long-term solution for dental restoration. The continued innovation in titanium dental implants promises to enhance patient satisfaction and expand the possibilities for restorative dental care.

Medical grade titanium is also used in cardiovascular devices, such as pacemaker casings and heart valve components. Its biocompatibility and corrosion resistant properties make it ideal for devices that must operate reliably within the human body for extended periods. The use of grade titanium in cardiovascular applications underscores its importance in life-saving technologies, where reliability and patient safety are paramount. Titanium's lightweight nature and high strength also contribute to the development of smaller, more efficient cardiovascular devices that can be implanted with minimal impact on the patient's lifestyle.

The role of grade titanium in cardiovascular devices extends to its use in stents and artificial heart components, where its properties support optimal performance and patient outcomes. As medical technology continues to advance, the integration of grade titanium in cardiovascular care will likely expand, offering innovative solutions for managing heart-related conditions and improving patient quality of life. The ongoing research into titanium's manufacturing processes and applications in cardiovascular medicine holds promise for future breakthroughs in patient care and treatment options.

Medical grade titanium is non-toxic and hypoallergenic, meaning it does not release harmful substances into the human body or cause allergic reactions. This safety profile is crucial for medical implant devices that need to remain in the body for a lifetime. The non-reactive nature of grade titanium ensures that it does not interfere with the body's natural processes, reducing the risk of complications and enhancing patient well-being. This makes grade titanium a preferred choice for patients with sensitivities or allergies to other metals, providing a safe and effective alternative for those requiring long-term titanium implant devices.

The hypoallergenic properties of grade titanium are particularly beneficial in environments where the immune system may be compromised, such as in patients undergoing chemotherapy or with autoimmune disorders. By minimizing the risk of allergic reactions, titanium implants allow these patients to receive necessary medical interventions without additional health concerns. This ability to cater to a wide range of patient needs highlights titanium's versatility and importance in modern medical practices.

Another benefit of titanium implants is their compatibility with medical imaging techniques like MRI and X-rays. Unlike some other metals, grade titanium does not interfere with these imaging processes, allowing healthcare professionals to monitor the medical implant and surrounding tissues effectively. This compatibility ensures that patients can receive accurate diagnoses and follow-up care without the limitations imposed by imaging artifacts or interference. The clarity provided by titanium's imaging compatibility is critical for ongoing patient management and the early detection of potential issues.

The ability to use advanced imaging techniques with titanium implants also facilitates surgical planning and post-operative evaluations. Surgeons can assess the position and condition of medical implant devices with precision, enabling them to make informed decisions and adjustments as needed. This level of insight is invaluable in ensuring successful surgical outcomes and optimizing patient recovery. As imaging technologies continue to evolve, the compatibility of grade titanium with these advancements will remain a significant advantage in medical diagnostics and treatment planning.

While titanium implant devices may be more expensive initially compared to other materials, their longevity and low risk of complications can lead to cost savings in the long run. Patients are less likely to need additional surgeries or replacements, which can be costly and stressful. The durability and reliability of medical implants contribute to reduced healthcare expenses over time, as they minimize the need for repeat procedures and extended recovery periods. This economic benefit is particularly important in healthcare systems striving to balance high quality care with cost-effectiveness.

The initial investment in titanium implants can be justified by the improved outcomes and patient satisfaction they provide. The reduction in complications and the extended lifespan of these medical implant devices translate into fewer healthcare resources being expended on corrective measures, benefiting both patients and providers. As healthcare continues to focus on value-based care, the use of grade titanium in medical implants is likely to be recognized as a cost-effective solution that supports positive patient experiences and outcomes.

Medical grade titanium offers numerous benefits for medical implants, from its high strength and durability to its excellent biocompatibility and corrosion resistant properties. These properties make it an ideal choice for a wide range of medical applications, ensuring that patients receive reliable and long-lasting titanium implant devices. The continued development and refinement of titanium-based technologies, including advanced manufacturing processes, promise to enhance patient care and expand the possibilities for medical treatments.

As technology advances, the use of grade titanium in medical devices manufacturing is likely to expand, offering even more innovative solutions for patient care. Whether for orthopedic implants, dental implants, or cardiovascular applications, grade titanium remains a critical material in advancing medical treatments and improving patient outcomes. The potential for grade titanium to revolutionize additional areas of medicine is vast, as researchers explore new applications and refine existing technologies.

Incorporating medical grade titanium into medical implants not only enhances the quality of life for patients but also represents a significant step forward in medical technology and materials science. The ongoing research and innovation in titanium implant applications are set to drive future advancements in healthcare, offering patients safer, more effective treatments and improving the overall standard of care. The future of medical implants is bright, with grade titanium leading the way in transforming patient experiences and outcomes.