AMS 4911 and AMS 4913 are important standards set by SAE International for titanium alloys, specifically for plate , sheet and strip forms. These standards make sure that materials meet certain rules for their physical properties, chemical makeup, and other key features. Following these rules is very important in fields like aerospace and medicine, where material failure can cause big problems. These strict guidelines make these materials reliable for many uses, including parts for airplanes, cars, and medical devices. They help manufacturers and engineers trust that the materials will work well even in tough conditions.

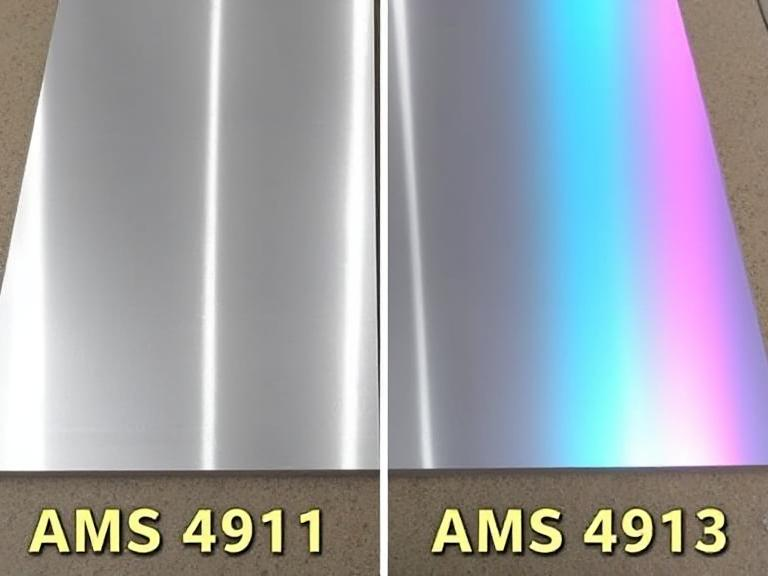

AMS 4911 refers to a specific type of titanium alloy, known as titanium 6Al-4V. This alloy is famous for its high strength, light weight, and excellent corrosion resistance. Its special mix of physical properties makes it a popular choice for many uses. It is often used where these features are critical, such as in aircraft parts and medical tools. This material is also used in sports gear, marine equipment, and even buildings, showing how useful it is when strength and performance are key. This grade is often processed as cold rolled sheet and strip.

AMS 4913 is another standard for titanium alloys, specifically for titanium 6Al-4V ELI (Extra Low Interstitial). The ELI version is made for uses that need better resistance to breaking and cracking under stress. These improvements make it a top choice for situations where materials face extreme stress and failure could be very serious. This makes it perfect for important uses in aerospace and the medical field. It is used for things like surgical implants and high-stress aircraft parts, where its better mechanical properties greatly improve safety and performance. This grade can also be found in forms like tube seamless.

Knowing the differences between 4911 titanium and AMS 4913 is key to choosing the right material. Each standard offers unique benefits that affect how well the material works for your project. Here are some main differences:

Both grades of titanium, AMS 4911 and AMS 4913, are based on the titanium 6Al-4V alloy. This alloy contains about 6% aluminum and vanadium. This mix gives a good balance of strength, weight, and corrosion resistance.

However, AMS 4913 has tighter controls on small elements like oxygen, nitrogen, and carbon. These strict controls lead to better flexibility and toughness, making AMS 4913 more suitable for uses where these mechanical properties are very important. It is considered a damage tolerant grade.

While both standards offer high strength and great corrosion resistance, AMS 4913 provides better toughness because of its ELI nature. This improved toughness means parts can handle more stress without breaking, which is vital in safety-critical uses. This makes it better for uses that need higher reliability and lasting power, such as medical implants and key aerospace parts. The ability to resist wear and stress corrosion shows how important it is to pick the right standard based on the demands of the use.

4911 titanium is widely used in aerospace for parts like aircraft frames and jet engine components. Its balance of strength and weight makes it perfect for high-performance uses, where making parts lighter without losing strength can greatly improve efficiency. This grade can be heat treatable, and often undergoes specific heat treatment processes like solution heat treated or beta annealed to achieve desired mechanical properties.

The ELI version, AMS 4913, is often chosen for medical implants, such as bone plates and screws. This is because of its excellent compatibility with the body and its resistance to wear. Its improved physical properties offer extra assurance of long life and good performance in critical medical uses, where patient safety is most important. This grade is also commonly used in tube seamless forms for various medical devices.

The choice between 4911 titanium and AMS 4913 depends on what your project specifically needs. Looking at the exact needs of your project will help you pick the best material. Here are some things to think about:

Cost: 4911 titanium is usually cheaper than AMS 4913. This is because the ELI version needs extra processing and tighter controls. This cost difference can be big, especially for large projects where money is a concern. If budget is tight and your use does not need the better features of AMS 4913, then 4911 titanium might be a better choice. But, it's important to compare the possible savings with how well the material needs to perform.

Performance: For uses where resistance to breaking and stress corrosion is critical, AMS 4913 is the better choice. Its improved mechanical properties give a safety margin and reliability that can be crucial in high-risk situations. This is especially true in medicine, where implant reliability directly affects patient safety. In aerospace, the extra toughness can mean better performance under stress, lowering the risk of failure during use.

Regulations: Both grades of titanium meet strict industry rules, making them suitable for tough uses. However, the choice might also depend on specific rules in certain fields. For example, makers of medical devices might prefer AMS 4913 because it meets strict body-friendly standards. Understanding these rules and industry expectations can help you pick the right standard for your needs.

Choosing between 4911 titanium and AMS 4913 depends on many things, including the specific use, performance needs, and budget. By understanding the main differences in chemical makeup, mechanical properties, and common uses, you can make a smart choice that fits your needs best. This understanding will ensure the material you pick works as expected, giving reliability and satisfaction in its use.

Whether you are designing aerospace parts or picking materials for medical implants, both grades of titanium, AMS 4911 and AMS 4913, offer good solutions. Their distinct benefits allow you to get the best performance and cost for your projects. However, thinking about the special benefits of each standard will ensure the best performance and long life for your uses.

In short, 4911 titanium offers a cost-effective solution with a good balance of physical properties for high-performance uses. AMS 4913 provides better toughness and reliability for critical, high-risk situations. Knowing these differences will help you choose the right titanium alloy standard for your project, leading to success and satisfaction.