Anodizing titanium is a cool way to change its surface and give it vibrant, lasting colors. It’s an electrochemical process that basically thickens the natural protective layer on the metal. The amazing part? The colors you see aren’t from dyes or paints; they’re created by how light interacts with this new, thicker oxide layer. This means the colors won’t fade or chip off, making anodized titanium super popular for things like jewelry, art, and even medical implants where both looks and durability matter.

Think of it like this: when you dip titanium into a special liquid (an electrolyte) and run electricity through it, the surface starts to oxidize. This creates a clear, super-thin layer. The thickness of this layer determines which colors of light get reflected and which get absorbed. By carefully controlling the electricity (specifically the voltage), you can make this layer thicker or thinner, producing a whole rainbow of colors. It’s a precise technique that gives you incredible control over the final look of your titanium pieces.

Anodizing titanium offers some fantastic perks:

Super Tough Against Rust: The process makes titanium’s natural protective layer even stronger, so it resists corrosion much better. This is great for anything exposed to moisture or harsh conditions, helping your titanium last longer.

Looks Amazing: You get stunning, bright colors without needing any dyes. The range of colors is huge, from soft pastels to eye-popping brights, perfect for adding a unique touch to your projects.

Body-Friendly: Anodized titanium is non-toxic and safe for medical uses, like implants or dental work. It won’t cause bad reactions in the body, which is why it’s a top choice for these critical applications.

Built to Last: The anodized layer isn’t just a coating; it’s actually part of the metal itself. This means it’s incredibly durable and won’t peel, chip, or flake off, keeping your pieces looking great for years.

Before you dive in, gather these essential items:

Titanium Piece: Whatever you want to color! Make sure it’s clean and hasn’t been treated with anything that might mess up the anodizing.

Power Supply: You’ll need a variable DC power supply. This lets you precisely control the voltage, which is key to getting the colors you want. (Think of it like a dimmer switch for electricity).

Anodizing Solution (Electrolyte): This is the special liquid your titanium will sit in. Common choices for home use include a mix of distilled water with Trisodium Phosphate (TSP) or Borax. These are generally safe and effective. Sulfuric acid is also used, but it’s more for industrial settings due to safety concerns. A good starting concentration is about 5 grams per liter (or 5 teaspoons per gallon) of distilled water.

Container: A plastic or glass container large enough to hold your titanium piece and the solution.

Cathode Material: Usually a piece of stainless steel or another titanium scrap. This completes the electrical circuit.

Wires and Clips: To connect everything electrically and ensure a stable connection.

Safety Gear: Absolutely essential! Wear gloves and eye protection (goggles) to shield yourself from the solution and any electrical mishaps.

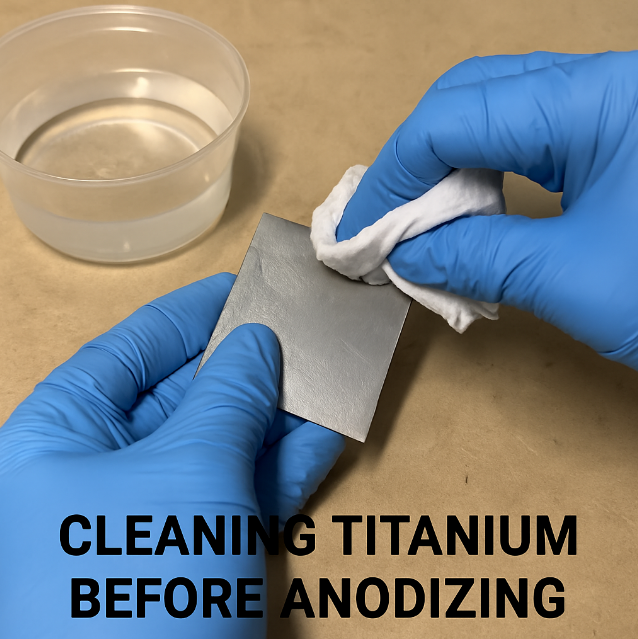

Cleaning Supplies: Detergent and isopropyl alcohol are a must to get your titanium super clean before you start.

Find a clean, well-ventilated spot. Set up your container on a steady surface and fill it with your anodizing solution. Make sure your titanium piece can be fully submerged. A tidy workspace isn’t just safer; it helps you focus. If possible, pick a spot where you can control things like humidity and temperature, as these can slightly affect the process.

This step is super important! Wash your titanium thoroughly with detergent, then rinse it well. Next, use isopropyl alcohol to wipe away any oils or grease, and rinse again. Finally, dry it completely with a lint-free cloth. Any dirt, oil, or fingerprints will prevent the anodizing from working evenly, leading to patchy colors. Pay extra attention to small nooks and crannies!

Attach your cathode material to one side of your container and connect it to the negative (-) terminal of your power supply. Then, connect your titanium piece to the positive (+) terminal. Double-check that all connections are tight and secure. A stable circuit is crucial for consistent voltage and getting the color you want.

Carefully place both your titanium piece and the cathode into the anodizing solution. Make absolutely sure they do not touch each other. Keeping them separate prevents short circuits and ensures the electricity flows correctly. Try to maintain a consistent distance between them for the most even results.

Turn on your power supply and slowly increase the voltage. This is where the magic happens! The voltage directly controls the color. Generally:

Lower voltages (around 15-20V) often give you golds and yellows.

Higher voltages (30-120V and up) can create blues, purples, and greens.

Watch the color change closely. Once you hit your desired shade, turn off the power and carefully remove the titanium from the solution. Patience is key here; letting the color fully develop will give you a brighter, more stable finish. It’s a good idea to keep notes on which voltages produce which colors for future reference!

Rinse your newly anodized titanium piece thoroughly in distilled water to wash off any leftover solution. Dry it with a clean cloth and check out the color. If you want a deeper or more consistent color, you can repeat the process. This final rinse is important to make sure no chemicals are left behind that could affect the look or durability of your anodized layer.

Patchy or Uneven Colors: This usually means your titanium wasn’t clean enough, or your electrical connections weren’t solid. Go back to Step 2 and 3, focusing on thorough cleaning and secure connections.

Colors Fade or Aren’t Consistent: Your power supply might not be holding a steady voltage. Make sure you’re using a reliable power supply and monitor the voltage throughout the process.

No Color Change: Double-check that you’ve set the correct voltage and that your titanium is definitely connected to the positive terminal (the anode). Also, inspect all your connections and the power supply itself.

Surface Finish Matters: Remember, the original finish of your titanium (e.g., polished, brushed, sandblasted) will affect the final color’s appearance. A highly polished surface will generally yield brighter, more vibrant colors than a matte finish.

To consistently get specific colors, start a

color chart! Write down the voltage settings you used and the colors you got. This is super helpful for reproducing your favorite hues in future projects. Don’t be afraid to experiment with different voltages and even how long you anodize to discover new color possibilities.

Want to get fancy? Use masking techniques to create patterns or designs. You can use adhesive vinyl or tape to cover parts of the titanium, preventing them from anodizing. This lets you create unique, personalized pieces with different colors or textures. Get creative with different masking materials to see what amazing effects you can achieve!

Seriously, safety is paramount. Always wear gloves and eye protection (goggles) to protect yourself from the anodizing solution and any electrical risks. Keep your workspace clean and clutter-free, and always check that your electrical equipment is in good working order. Inspect your gear regularly for any wear or damage and replace anything faulty immediately. A safe setup means a smooth and successful anodizing experience.

Yes, you absolutely can anodize titanium right in your own home! With the right tools and a bit of care, even beginners can get fantastic, professional-looking results. It’s a wonderful way to unleash your creativity and add a personal touch to your titanium items. Doing it yourself gives you the freedom to experiment and customize to your heart’s content.

By following this guide and practicing a bit, you’ll quickly get the hang of it and be able to create beautiful, high-quality anodized titanium pieces. Whether you’re making jewelry, art, or practical items, anodizing offers a unique and durable finish that truly stands out.

Anodizing titanium is a really satisfying process that turns ordinary metal into vibrant, corrosion-resistant works of art. By following this simple, step-by-step guide, you can confidently anodize titanium at home and enjoy the stunning results. It’s perfect for jewelry, art, or just making everyday items look extraordinary.

So go ahead, embrace the art of anodizing! With a little practice and patience, you’ll master this technique and create gorgeous, long-lasting anodized titanium pieces. Happy anodizing!