Raw titanium metal is one of the most sought-after materials in modern industry. Why? Because this unique metal offers an incredible mix of strength, lightness, and resistance to corrosion that few other materials can match. From jet engines to medical implants, the demand for titanium raw material is constantly growing. This article will dive into the core features of pure titanium metal, explore the vast titanium alloy applications, and help you understand how to connect with reliable titanium metal suppliers.

The starting point: Raw Titanium Metal in its sponge or ingot form.

When we talk about titanium titanium metal, we are referring to a transition metal known for its exceptional performance. It's not just one material; it comes in different forms, mainly commercially pure titanium and its alloys. The choice between them depends entirely on the job at hand.

The success of titanium and titanium alloys metal raw materials is built on a foundation of superior physical and chemical traits. Here are the most important titanium metal characteristics:

Incredible Strength-to-Weight Ratio: Titanium is as strong as some steels but weighs nearly 45% less. This is a game-changer for any application where weight matters.

Outstanding Corrosion Resistance: Titanium naturally forms a protective oxide layer, making it virtually immune to rust and corrosion, even in harsh environments like seawater and chemical plants.

Biocompatibility: Pure titanium metal is non-toxic and integrates perfectly with the human body, making it the top choice for medical implants.

Thermal Stability: It keeps its strength even at very high temperatures, which is crucial for aerospace and high-performance engine parts.

The world of titanium titanium alloys metal raw materials is divided into two main categories:

Commercially Pure Titanium (CP Ti): Graded 1 through 4, this is essentially pure titanium metal. It's softer and more ductile (easy to shape) but still incredibly corrosion-resistant. Grade 1 is the most ductile, while Grade 4 is the strongest.

Titanium Alloys: These are created by mixing titanium with other elements like aluminum, vanadium, or molybdenum. The most famous is Ti-6Al-4V (Grade 5). These alloys offer much higher strength and durability, perfect for the most demanding titanium alloy applications.

The unique titanium metal properties translate into significant advantages across various industries. Understanding these titanium metal benefits helps explain its high value:

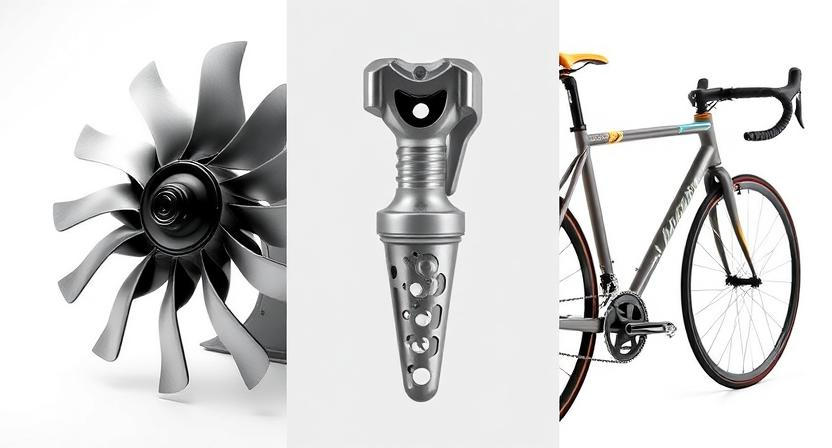

Versatility in action: Key titanium alloy applications in aerospace, medical, and sports.

The applications for titanium and titanium alloys metal raw materials are vast and continue to grow:

Aerospace and Defense: Used in jet engine components, airframe structures, and missile parts due to its light weight and high-temperature resistance.

Medical and Dental: The gold standard for joint replacements, dental implants, and surgical tools because of its unmatched biocompatibility.

Automotive: High-performance cars use titanium for exhaust systems and engine valves to reduce weight and improve efficiency.

Chemical Processing: Tanks, heat exchangers, and pipes benefit from its extreme corrosion resistance against aggressive chemicals.

Consumer Goods: Used in high-end sports equipment (golf clubs, bicycles) and luxury items (watches, jewelry) for its durability and premium feel.

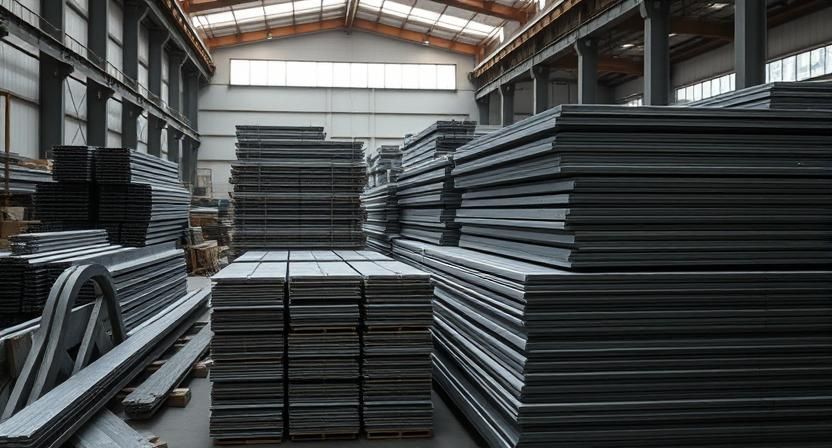

Whether you need titanium raw material for a small project or bulk quantities for manufacturing, connecting with the right titanium metal suppliers is crucial. Suppliers offer titanium in various forms, including sponge, ingots, billets, bars, sheets, and wires.

For a reliable source of high-quality titanium and titanium alloys metal raw materials, we recommend checking out www.chinatitaniumfactory.com. They specialize in providing certified pure titanium metal and alloys for various demanding titanium alloy applications, ensuring you get the best material for your needs.

When choosing a supplier, always consider their certification (especially for aerospace and medical grades), their ability to provide the specific grade you need (e.g., Grade 2 pure titanium metal or Grade 5 alloy), and their quality control processes.

| Factor | Why It Matters |

|---|---|

| Certification | Ensures the material meets industry standards (e.g., ASTM, ISO). |

| Grade Availability | Do they stock the specific titanium titanium alloys you require? |

| Quality Control | Look for suppliers with strict testing and traceability procedures. |

| Form/Shape | Can they provide the material in the required form (sheet, bar, powder)? |

A reliable titanium metal supplier ensures quality and traceability of the raw material.

The process of turning titanium raw material (found in minerals like rutile and ilmenite) into usable titanium metal is complex and energy-intensive. The most common method is the Kroll process, which involves several steps to reduce titanium tetrachloride into a porous material called titanium sponge. This sponge is then melted and refined to create the final ingots, which are the starting point for all other titanium titanium metal products.

Raw titanium metal is truly a material of the future. Its unique combination of titanium metal properties—high strength, low weight, and supreme corrosion resistance—makes it indispensable for critical applications. From the deep sea to outer space, titanium and titanium alloys metal raw materials are enabling engineers to build lighter, stronger, and more durable products. By understanding the different grades, the powerful titanium metal benefits, and how to source from quality titanium metal suppliers, you can leverage this amazing element for your next project.