Custom Anode Complexity: Bespoke titanium anodes require precise engineering, impacting design, material selection, and manufacturing lead times.

Lead Time Drivers: Factors like raw material availability, coating technology, and quality assurance significantly influence the overall production schedule.

Global Logistics Mastery: Effective international shipping, including specialized packaging and customs navigation, is crucial for timely and secure delivery.

Supply Chain Resilience: Proactive risk management and transparent communication are vital for mitigating disruptions and ensuring reliability.

Strategic Partnership: Collaborating with an experienced manufacturer like China Titanium Factory streamlines procurement and optimizes project timelines.

Precision Engineering: What Defines a Custom Titanium Anode?

Navigating Global Logistics: Efficient Shipping for Your Anode Orders

Proactive Strategies for Supply Chain Resilience and On-Time Delivery

Commitment to Sustainability: Eco-Conscious Anode Production and Logistics

Partnering for Efficiency: Your Strategic Choice for Custom Anodes

The procurement of custom titanium anodes is a critical aspect of numerous industrial applications, ranging from chemical processing to wastewater treatment. Ensuring procurement efficiency necessitates meticulous lead time management and robust global logistics.

These specialized components are integral to electrochemical processes, where their performance directly impacts operational success and cost-effectiveness. A reliable supply chain is paramount for maintaining continuous production and avoiding costly downtime across various industrial applications.

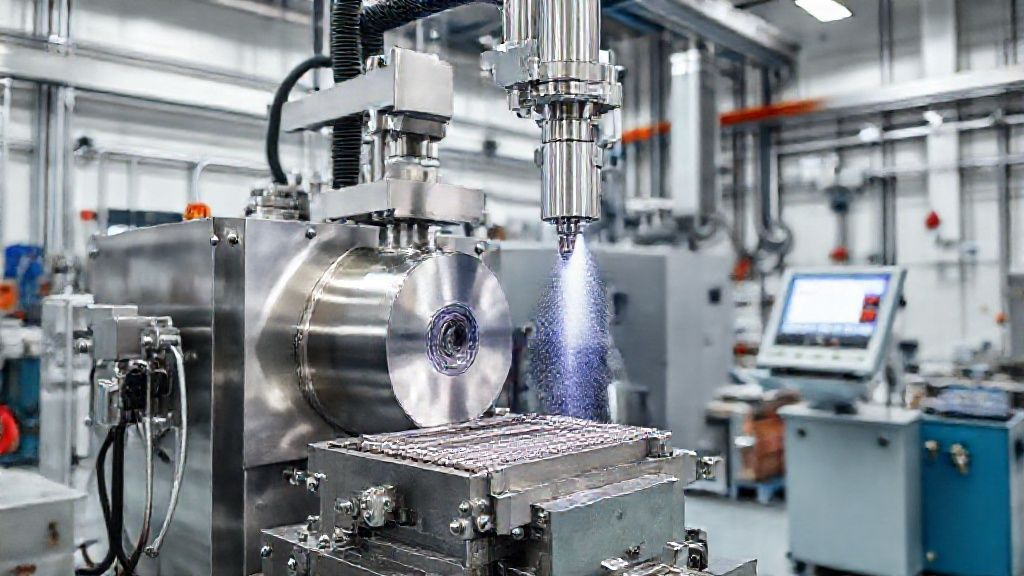

A custom titanium anode is a highly specialized electrode engineered for specific electrochemical environments. Its fundamental composition involves a titanium substrate, which provides excellent corrosion resistance and mechanical strength.

This substrate is typically coated with a catalytic coating, often composed of Mixed Metal Oxides (MMO), platinum, or other noble metals. The coating is meticulously selected and applied to optimize performance for particular reactions, such as chlorine evolution, oxygen evolution, or cathodic protection.

Definition: A Custom Titanium Anode refers to an electrode precisely engineered with a titanium base and a specialized catalytic coating, designed to meet the unique current density, longevity, and selectivity requirements of a specific electrochemical process or application.

The necessity for custom anode specifications arises from the diverse demands of electrochemical applications. Factors like electrolyte composition, operating temperature, current density, and desired reaction products dictate the precise anode design principles.

Bespoke design ensures optimal efficiency, extended service life, and minimized energy consumption. Organizations seeking such tailored solutions can explore the capabilities offered by China Titanium Factory's services, which encompass comprehensive engineering and manufacturing for complex industrial needs.

The choice and application of the catalytic coating are paramount. It dictates the anode's electrochemical activity, selectivity, and lifespan. A well-engineered coating can dramatically reduce operating costs and enhance process efficiency. Manufacturers with deep expertise in coating technologies are crucial for optimal anode performance.

Understanding the factors that influence lead times for custom titanium anodes is essential for effective project planning. The process typically begins with the anode design phase, involving detailed engineering and client consultation.

This stage includes material selection, geometric configuration, and coating specification, directly impacting subsequent production steps. Accurate design minimizes revisions and accelerates the overall timeline.

Following design approval, material procurement commences. Sourcing high-grade titanium and precious metal precursors for coatings can be subject to global supply chain dynamics. Reputable suppliers, like those partnered with China Titanium Factory, prioritize stable and efficient material acquisition.

The manufacturing timeline encompasses substrate fabrication, surface preparation, and the multi-layer application of catalytic coatings. Each step requires specialized equipment and skilled technicians. Production scheduling is optimized to manage multiple orders without compromising quality.

Rigorous quality control processes are integrated throughout production, from raw material inspection to final performance testing. This phase, while crucial for product integrity, adds to the overall lead time. Thorough testing ensures anodes meet specified electrochemical properties and durability standards.

For projects requiring expedited lead times, manufacturers can implement strategies such as pre-ordering common raw materials or allocating dedicated production lines. However, this often involves a premium due to resource prioritization. For a detailed discussion on project timelines, direct consultation is recommended.

| Stage | Description | Impact on Lead Time |

|---|---|---|

| Design & Engineering | Client specification, CAD modeling, material selection, coating formulation. | Highly variable (1-4 weeks), depending on complexity and client feedback. |

| Material Procurement | Sourcing titanium sheet/mesh, precious metal precursors for coatings. | Moderate (2-6 weeks), influenced by global supply and specific material availability. |

| Fabrication & Coating | Substrate shaping, surface treatment, multi-layer coating application, curing. | Significant (4-12 weeks), depending on anode size, quantity, and coating complexity. |

| Quality Assurance & Testing | Visual inspection, adhesion tests, electrochemical performance validation. | Consistent (1-2 weeks), critical for product reliability. |

| Packaging & Pre-shipment | Custom packaging, labeling, documentation preparation. | Short (0.5-1 week), but crucial for safe transit. |

The successful delivery of custom titanium anodes hinges on robust international shipping solutions. Specialized logistics management is required to ensure that these sensitive and valuable components arrive safely and on schedule, regardless of destination.

Various freight forwarding options are employed, including air freight for urgent deliveries, sea freight for cost-effectiveness and larger volumes, and land transport for regional distribution. Each method is selected based on client requirements for speed, cost, and cargo size.

Secure packaging standards are non-negotiable for anodes. Custom crating, anti-corrosion wraps, and shock-absorbent materials protect against physical damage and environmental factors during transit. This meticulous approach safeguards the integrity of the catalytic coating and substrate.

Effective customs documentation and clearance procedures are critical for avoiding delays. Expertise in logistics management ensures compliance with diverse international trade regulations, minimizing potential issues at borders. This proactive approach contributes significantly to reliable global delivery timelines.

Organizations benefit from partners who offer end-to-end logistics support, handling all aspects from factory gate to final destination. For more information on shipping capabilities, clients can refer to China Titanium Factory's contact page for direct inquiries.

Ensuring the reliable and punctual fulfillment of custom anode orders demands a robust approach to supply chain risk management. Proactive measures are implemented to anticipate and mitigate potential disruptions, safeguarding project timelines.

Contingency planning includes diversifying raw material suppliers and maintaining buffer stocks of critical components. This strategy minimizes vulnerabilities to geopolitical events, natural disasters, or unexpected material shortages.

Transparent communication channels are maintained with clients at every stage of the order process. Regular updates on production status, shipping milestones, and potential adjustments ensure stakeholders are fully informed. This fosters trust and allows for collaborative problem-solving.

Advanced order tracking systems provide real-time visibility into shipment progress. Clients can monitor their orders from dispatch to delivery, enhancing predictability and control. This level of transparency is crucial for managing complex international projects.

Furthermore, adherence to customs compliance and a deep understanding of global trade regulations prevent unnecessary delays. Experienced logistics teams manage all required declarations and certifications, streamlining international transit. This commitment ensures consistent delivery reliability.

Definition: Supply Chain Resilience refers to the ability of a supply chain to prepare for and adapt to unexpected disruptions, maintaining continuity of operations and delivery performance in the face of adverse events.

Leveraging digital platforms and API integrations with freight carriers can provide granular, real-time data on shipment status. This not only enhances visibility for clients but also enables predictive analytics for potential delays, allowing for proactive intervention.

Demonstrated success in managing complex anode project success and intricate logistics is a hallmark of a reliable partner. Case studies highlight the ability to navigate stringent deadlines and unique custom anode specifications.

One notable logistics case study involved a large-scale chlor-alkali plant requiring a complete set of replacement anodes within a tight shutdown window. Through precise production scheduling and expedited air freight, the entire order was delivered two days ahead of schedule, minimizing plant downtime and saving significant operational costs. This exemplifies on-time delivery success.

Client testimonials consistently praise the transparent communication and proactive problem-solving employed during complex order fulfillment. For instance, a client in the hydrometallurgy sector lauded the seamless coordination for a multi-phase project involving anodes with specialized coatings, delivered across three continents.

These instances underscore a commitment to customer satisfaction and the proven capability to execute demanding projects. Organizations can inquire about specific project examples by reaching out to the experts at China Titanium Factory's blog or contacting their sales team directly.

Further insights into industrial best practices for supply chain management can be found from reputable industry sources such as ISM (Institute for Supply Management), which regularly publishes research on procurement and logistics excellence.

The industrial sector increasingly recognizes the importance of environmental responsibility. This extends to the manufacturing and delivery of custom titanium anodes, where sustainable manufacturing practices are actively implemented.

Sustainable anode production involves optimizing energy consumption during fabrication and coating processes. This includes investing in energy-efficient machinery and implementing waste reduction strategies, particularly concerning precious metal usage.

Eco-friendly shipping and green logistics initiatives are integrated into global delivery strategies. This can involve optimizing shipping routes to reduce fuel consumption, consolidating shipments, and utilizing packaging materials that are recyclable or made from recycled content.

The goal is to achieve a reduced carbon footprint across the entire anode lifecycle. By prioritizing sustainable practices, manufacturers contribute to broader ecological objectives without compromising product quality or delivery efficiency.

For more information on industrial sustainability benchmarks, organizations can consult resources from bodies like the United Nations Sustainable Development Goals, which provide a global framework for responsible industrial practices.

Selecting the right anode supplier partnership is a strategic decision for industrial operations. It directly influences project timelines, operational costs, and the overall success of electrochemical processes. A partner offering optimized procurement solutions is invaluable.

Manufacturers like China Titanium Factory provide a combination of technical expertise and unwavering reliability. Their comprehensive understanding of anode design, manufacturing, and global logistics ensures that client requirements are met with precision and efficiency.

The commitment to customer support excellence ensures that clients receive tailored solutions and continuous communication. This client-centric approach positions the manufacturer as a true strategic sourcing partner, not merely a vendor.

By leveraging advanced manufacturing capabilities and a robust global supply chain, a reliable anode source minimizes risks and maximizes operational uptime for industries worldwide. This partnership approach ensures long-term value and sustained performance.

Organizations seeking a partner for custom titanium anodes are encouraged to contact China Titanium Factory to discuss their specific project requirements and explore tailored solutions.

Partner with an industry leader for precision-engineered custom titanium anodes, streamlined lead times, and reliable global delivery.

Request a Consultation TodayTypical lead times for custom titanium anodes vary significantly based on design complexity, material availability, and order volume. Generally, clients can expect lead times ranging from 8 to 16 weeks, encompassing design, material procurement, manufacturing, and quality assurance. Specific delivery estimates are provided upon detailed project assessment.

Shipping costs are calculated based on several factors, including the total weight and dimensions of the packaged anodes, the chosen shipping method (air, sea, or land freight), destination country, and any special handling or insurance requirements. Quotations are provided on a project-specific basis, ensuring transparency.

Customs duties and import regulations vary by destination country. The client is typically responsible for these charges. Expert logistics teams assist with accurate documentation and classification to ensure compliance with international regulations, facilitating smooth customs clearance. For specific details, consultation with local customs authorities or a freight forwarder is recommended.

Yes, expedited lead times for both manufacturing and shipping can be arranged for urgent requirements. This often involves prioritizing production scheduling and utilizing faster, premium freight services. Such requests are evaluated on a case-by-case basis, and any associated surcharges are communicated transparently during the order process.

Anodes are packaged using robust, secure packaging standards designed to prevent damage during international transit. This typically includes custom-built wooden crates, anti-corrosion materials, shock-absorbing foam, and secure strapping. The packaging is tailored to the anode's specific dimensions and fragility to ensure it arrives in pristine condition.