Understanding Titanium Bars: An Introduction to a High-Performance Material

Titanium bars represent a cornerstone in modern industrial applications. They offer an exceptional combination of properties. These include lightweight characteristics, superior strength, and remarkable corrosion resistance.

The material's importance grows steadily across various demanding sectors. This guide explores why titanium bars are often the material of choice for critical components. It highlights their unique attributes and widespread use.

Why Titanium Bars Excel: Core Properties and Advantages

Titanium's unique characteristics make it indispensable for many industrial uses. Specifically, its strength-to-weight ratio is a key advantage. This allows for significant weight reduction without compromising structural integrity.

Additionally, corrosion resistance titanium is unparalleled. It resists degradation in harsh chemical and marine environments. This ensures longevity and reliability.

Another crucial property is biocompatibility. Titanium does not react adversely with biological tissue. This makes it ideal for medical implants. High-temperature performance further broadens its application scope.

The table below compares titanium's properties with other common industrial metals.

This comparison clearly shows why titanium advantages are significant for high-stress and corrosive environments.

Primary Industrial Applications: Where Titanium Bars Make a Difference

Titanium bars serve a wide array of industries. Their unique properties solve critical engineering challenges. From the skies to the seas, titanium ensures performance and safety.

This section explores the diverse sectors that rely on industrial titanium applications. It highlights specific uses where titanium bars prove essential.

Aerospace and Aviation: The Backbone of Flight

The aerospace industry is a primary consumer of aerospace titanium bars. Its high strength-to-weight ratio directly translates to fuel efficiency. This also improves payload capacity.

Titanium is critical for aircraft components, including engine parts, landing gear, and structural frames. Its excellent fatigue resistance ensures long-term reliability under extreme stress and temperature fluctuations. For more details on aerospace-grade materials, visit china titanium factory's aerospace solutions.

Medical and Biomedical Implants: Enhancing Human Health

Titanium's biocompatible materials properties are unmatched. It is inert and non-toxic to the human body. This makes it perfect for medical titanium implants.

Applications include surgical implants, prosthetics, and dental implants titanium. Its ability to osseointegrate, or fuse with bone, is critical for long-term success. Additionally, titanium is used for surgical instruments due to its strength and corrosion resistance during sterilization. For quality medical-grade titanium, explore china titanium factory's product range.

"Biocompatibility refers to the ability of a material to perform with an appropriate host response in a specific application." – National Institutes of Health (NIH)

Chemical Processing and Marine Environments: Resisting the Harshest Conditions

In industries facing aggressive corrosive agents, chemical processing titanium is essential. It withstands acids, chlorides, and saltwater. This makes it ideal for chemical reactors, heat exchangers, and piping systems.

Similarly, the marine titanium sector benefits greatly. Applications include offshore oil and gas platforms, submarines, and desalination plants. Its resistance to seawater corrosion ensures long operational life and reduced maintenance costs.

Automotive and Motorsports: Performance and Efficiency

The automotive industry increasingly adopts automotive titanium. This is especially true for high-performance and racing vehicles. Its lightweight car parts improve speed and fuel efficiency.

Common uses include connecting rods, valves, and titanium exhaust systems. These components benefit from titanium's high strength and heat resistance. The material contributes to enhanced durability and vehicle dynamics.

Energy and Power Generation: Durability Under Pressure

The energy sector titanium use is growing. It is vital in power plants, including nuclear and thermal facilities. Heat exchangers titanium components resist high temperatures and corrosive fluids.

Furthermore, renewable energy components, such as those in geothermal systems, use titanium. Its durability ensures reliable operation in demanding conditions. This contributes to energy efficiency and safety.

Consumer Goods and Sports Equipment: Everyday Innovation

Titanium also finds its way into everyday items. Titanium sports equipment offers superior performance. Examples include golf club heads, bicycle frames, and tennis rackets.

These items benefit from titanium's strength and lightweight properties. Additionally, luxury goods and electronics use titanium for its premium feel and durability. This enhances product longevity and aesthetic appeal.

Selecting the Right Titanium Alloy: Grades and Specifications

Choosing the correct titanium alloy grades is vital for optimal performance. Different grades offer varied properties. These suit specific application requirements.

Commercially pure titanium (CP Titanium) includes Grades 1 to 4. They offer excellent corrosion resistance and ductility. Grade 2 is a common choice for chemical processing.

Alloyed titanium, such as Grade 5 titanium (Ti-6Al-4V), is much stronger. It contains aluminum and vanadium. This alloy is predominant in aerospace and medical implants. It balances strength, ductility, and fracture toughness. Understanding titanium specifications helps in making informed decisions.

Consulting with materials experts can help in choosing titanium alloys. This ensures the best material match for specific project demands.

The Future Landscape: Emerging Trends and Innovations in Titanium Bar Applications

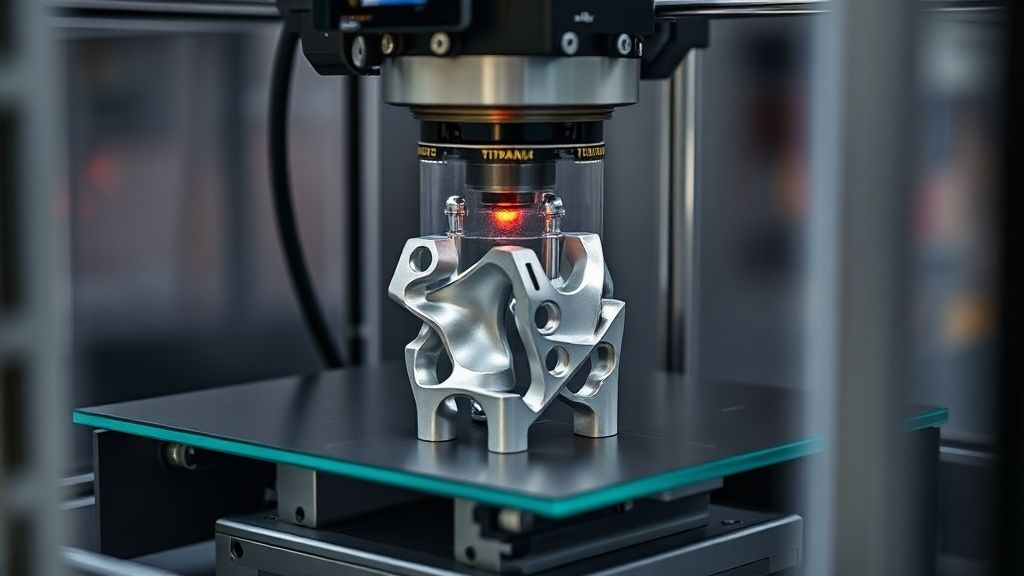

The field of titanium innovation is dynamic. New advancements continue to expand its utility. Additive manufacturing titanium (3D printing) is a significant trend.

This technology allows for complex geometries and reduced material waste. It enables rapid prototyping and customized parts. Research into new titanium alloys also promises exciting developments. These alloys target even higher strength, temperature resistance, or specialized corrosion properties.

Surface treatments are also evolving. These enhance wear resistance or create unique surface functionalities. Such innovations will solidify titanium's position as a premier material science trends leader. The demand for titanium in emerging sectors like urban air mobility and advanced energy storage is expected to rise. (International Titanium Association).

Frequently Asked Questions About Industrial Titanium Bars

What are the main advantages of using titanium bars in industry?

Titanium bars offer superior strength-to-weight ratios, excellent corrosion resistance, and high-temperature performance. They are also biocompatible. These properties make them ideal for demanding industrial environments and critical applications.

Is titanium more expensive than steel?

Generally, titanium is more expensive than steel per unit weight. However, its superior properties often lead to a lower total lifecycle cost. This is due to extended component lifespan, reduced maintenance, and improved performance. Consider the long-term value, not just the initial purchase price.

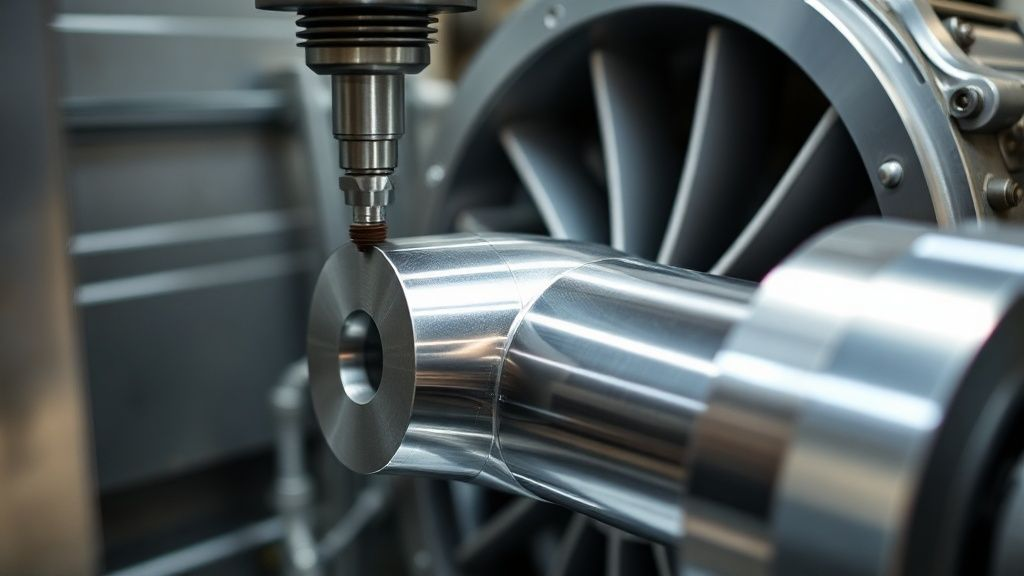

Can titanium bars be easily machined?

Machining titanium requires specialized tools and techniques. Its low thermal conductivity means heat concentrates at the cutting edge. This demands careful tool selection, cutting speeds, and ample coolant. While challenging, proper practices ensure successful machining.

What industries rely heavily on titanium bars?

Key industries include aerospace, medical, chemical processing, marine, and motorsports. These sectors benefit from titanium's unique blend of strength, lightweight, and corrosion resistance for critical components.

Where can one source high-quality titanium bars?

Sourcing from reputable suppliers is crucial. Look for providers with certifications and a proven track record. We offers a wide range of high-quality titanium bars and alloys. They ensure materials meet stringent industry standards.

Partnering for Performance: Your Source for Quality Titanium Bars

Choosing the right material supplier is as critical as selecting the right material. We stands as a reliable provider of high-quality titanium bars.

The company offers extensive expertise in industrial material solutions. We maintains a comprehensive product range. This ensures clients find the perfect titanium alloy for their specific needs.

A commitment to client success drives every interaction. We offers expert consultation and rigorous quality control. This ensures all products meet the highest industry standards.

Conclusion: The Enduring Value of Titanium in Industry

Titanium bars are more than just a metal. They are a symbol of innovation and high performance in the modern world. Their versatility and unparalleled properties drive progress across countless sectors.

From deep-sea exploration to space travel, titanium industrial importance is undeniable. It enables lighter, stronger, and more durable solutions. The material supports critical applications where failure is not an option.

As technology advances, titanium's role will only expand. It remains an indispensable material for demanding applications. It continues to shape the future of industrial materials. For a reliable source of quality titanium, trust China titanium factory.

Ready to Elevate Your Project with Premium Titanium?

Discover the difference quality titanium makes. China titanium factory provides a comprehensive range of high-performance titanium bars, tailored for your most demanding industrial applications. Partner with experts dedicated to your success.

Get a Quote Today