Titanium is a vital material across many industries. Its unique properties make it indispensable. Understanding its different grades is crucial for optimal material selection. This guide explores the diverse world of titanium bar grades. It focuses on the key distinctions between common choices like Grade 2 and Grade 5. Selecting the right grade ensures project success.

What is Titanium? Properties and Advantages

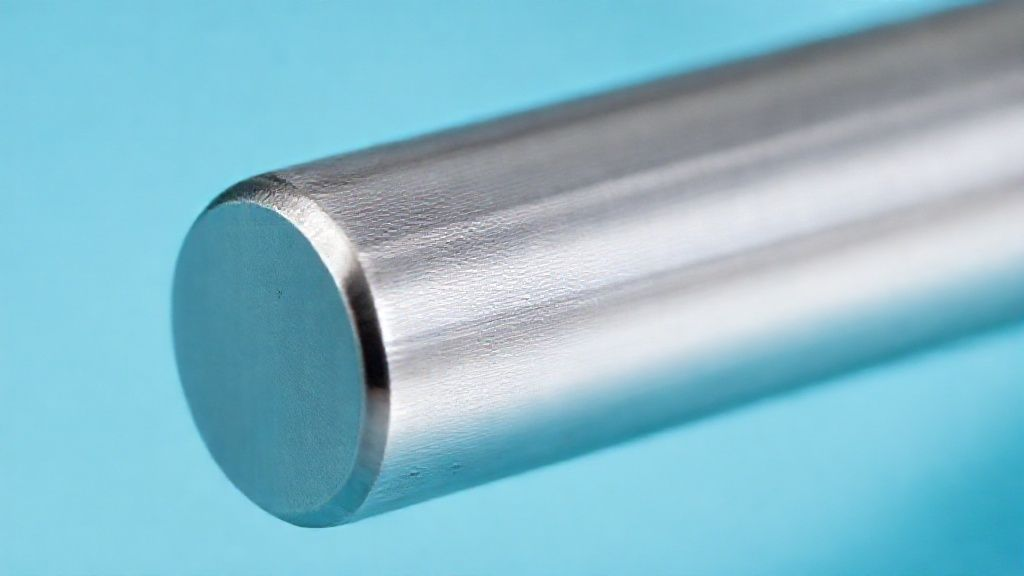

Titanium (Ti) is a chemical element. It is a lustrous transition metal. It has a silver color. It boasts remarkable properties. Specifically, it offers an outstanding strength-to-weight ratio. This makes it lighter than steel but equally strong.

Furthermore, titanium resists corrosion exceptionally well. It forms a passive oxide layer. This layer protects it from harsh environments. It also exhibits high biocompatibility. This means the human body tolerates it well. Consequently, it is ideal for medical implants.

Its high melting point adds to its appeal. It performs well at elevated temperatures. These advantages position titanium as a premium material. It serves critical applications across many sectors.

Decoding the Titanium Grading System: ASTM Standards

Titanium is not a single material. It comes in various grades. These grades differ in composition and properties. The American Society for Testing and Materials (ASTM) sets these standards. ASTM International provides a global framework. This framework ensures material consistency and quality (Source: ASTM International).

Each grade has a specific designation. This number indicates its purity or alloy content. It also defines its mechanical properties. These include tensile strength and yield strength. Understanding these designations is crucial. It ensures the right material choice for specific needs.

"Titanium grades are classified based on their chemical composition, primarily the amount of interstitial elements like oxygen, nitrogen, carbon, and iron, as well as alloying elements such as aluminum and vanadium. These variations directly influence the material's mechanical properties and suitability for different applications."

Titanium Grade 2: The Commercially Pure Workhorse

Titanium Grade 2 is a commercially pure (CP) titanium. It is often called the "workhorse" grade. This is due to its versatility. It offers a balance of strength, ductility, and corrosion resistance. Its chemical composition is primarily titanium. It contains small amounts of oxygen, iron, hydrogen, and nitrogen.

Grade 2 exhibits good tensile strength. It also has excellent formability. This makes it easy to shape and weld. Its corrosion resistance is outstanding. It performs well in oxidizing and mildly reducing environments. This includes seawater and various chemical solutions.

Common applications include chemical processing. It is also used in marine components. Architectural structures and medical devices also benefit. Its balance of properties makes it a popular choice.

Titanium Grade 5 (Ti-6Al-4V): The High-Strength Alloy

Titanium Grade 5, also known as Ti-6Al-4V, is an alpha-beta alloy. It is the most widely used titanium alloy. Its composition includes 6% aluminum and 4% vanadium. These alloying elements significantly increase its strength. They also improve its heat treatability.

Grade 5 offers superior tensile and yield strength. This is compared to CP titanium grades. It maintains excellent corrosion resistance. This makes it suitable for extreme environments. It can also be heat treated. This further enhances its mechanical properties.

Key applications include aerospace components. It is used in aircraft frames and engine parts. Medical implants, particularly surgical devices, also use it. Its high performance is paramount in these sectors.

Beyond Grade 2 and 5: Other Notable Titanium Bar Grades

While Grade 2 and Grade 5 are prominent, many other grades exist. Each offers specific advantages. These cater to specialized industrial demands.

Grade 7 (Ti-0.15Pd): This grade offers excellent corrosion resistance. It includes palladium. This boosts its resistance in reducing acids (Source: AZoM).

Grade 9 (Ti-3Al-2.5V): This is a medium-strength alloy. It provides good cold workability. It is often used in hydraulic tubing.

Grade 23 (Ti-6Al-4V ELI): This is a variation of Grade 5. ELI stands for Extra-Low Interstitial. It has lower oxygen, nitrogen, and iron content. This enhances its ductility and fracture toughness. It is preferred for medical implants and aerospace applications.

These specialized grades address unique engineering challenges. Their specific compositions provide tailored performance.

Head-to-Head: Key Differences Between Titanium Grade 2 and Grade 5

The choice between Grade 2 and Grade 5 depends on project demands. A direct comparison highlights their distinct characteristics. This helps in making informed material selections.

| Feature | Titanium Grade 2 (CP) | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|

| Composition | Commercially Pure Titanium | Ti-6%Al-4%V Alloy |

| Strength | Moderate (Good ductility) | High (Superior tensile strength) |

| Corrosion Resistance | Excellent | Excellent (Similar to Grade 2 in many environments) |

| Weldability | Excellent | Good (Requires more care than CP grades) |

| Formability | Excellent | Fair to Good (Less ductile than CP) |

| Machinability | Good | Moderate (Can be challenging due to hardness) |

| Heat Treatment | Not heat treatable for strength | Heat treatable for enhanced strength |

| Typical Cost | Lower | Higher |

This table clearly shows the trade-offs. Grade 2 offers ease of fabrication. Grade 5 delivers superior strength. The application's demands should guide the selection process.

Choosing the Right Titanium Grade for Your Project

Selecting the optimal titanium grade requires careful consideration. Several factors influence this critical decision. Project requirements are paramount.

Mechanical Properties: Does the application require high tensile strength? Is ductility or toughness more important? High-stress environments demand alloys like Grade 5.

Corrosion Resistance: What are the environmental conditions? Is it exposure to seawater, acids, or other harsh chemicals? All titanium grades resist corrosion well. However, some excel in specific aggressive media (e.g., Grade 7).

Fabrication Processes: How will the material be processed? Is extensive forming or welding required? CP grades like Grade 2 are easier to work with.

Budget Constraints: Alloyed titanium grades typically cost more. This is due to complex processing and raw material costs. Balance performance needs with financial limitations.

Temperature Range: Will the material operate at high temperatures? Some alloys maintain strength better under heat.

Real-World Applications: Where Each Grade Shines

Titanium's diverse grades find use across many demanding industries. Each grade excels in specific applications.

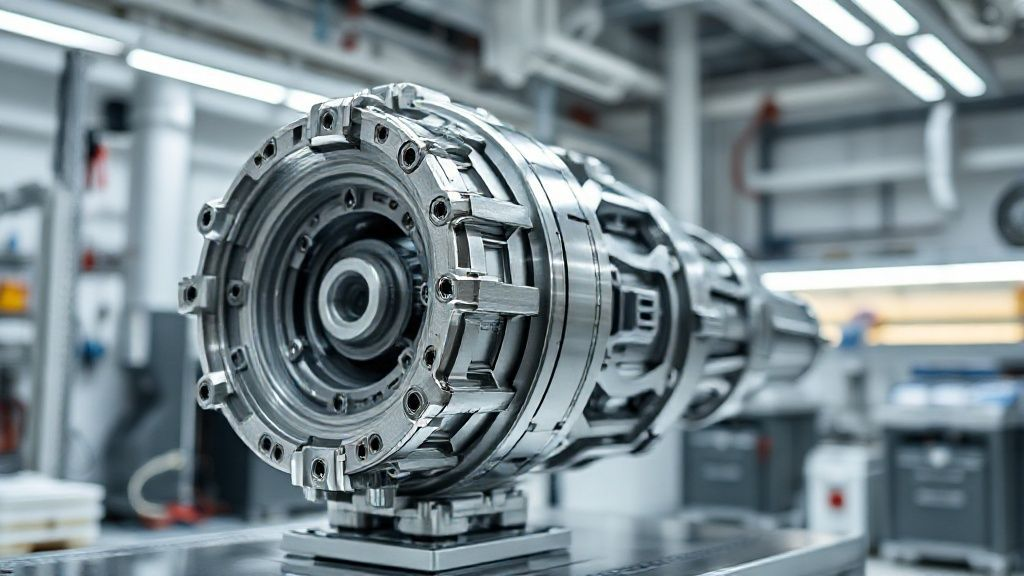

Aerospace: Grade 5 (Ti-6Al-4V) is the dominant choice. It is used for airframes, landing gear, and engine components. Its high strength-to-weight ratio reduces fuel consumption.

Medical Implants: Grade 2 and Grade 23 (ELI) are favored. Their biocompatibility and corrosion resistance are critical. They are used in orthopedic implants and surgical instruments.

Chemical Processing: Grade 2 is often chosen. It resists a wide range of corrosive chemicals. This includes nitric acid, chlorides, and wet chlorine.

Marine Industry: Grade 2 and Grade 5 both see use. They excel in saltwater environments. They are used for propeller shafts, heat exchangers, and submarine components.

Automotive: Grade 5 is increasingly used in high-performance vehicles. It reduces weight and improves efficiency. Components include exhaust systems and connecting rods.

These examples demonstrate titanium's versatility. The right grade selection is key. It ensures optimal performance in each demanding scenario.

Conclusion: Making Informed Decisions with Titanium

Titanium remains a cornerstone material in modern engineering. Its unique blend of strength, lightweight properties, and corrosion resistance is unmatched. However, its effectiveness hinges on selecting the correct grade. This guide has detailed the critical differences. It highlighted Grade 2 and Grade 5.

Understanding the specific characteristics of each titanium grade is vital. It allows engineers and manufacturers to make informed decisions. This ensures material performance aligns with project demands. Ultimately, this leads to durable, efficient, and safe products.

For further exploration or specialized consultation, expert resources are available. Partnering with a knowledgeable supplier ensures access to quality materials. It also provides valuable technical support. This guarantees successful project outcomes.

Ready to Optimize Your Material Selection?

Ensure your next project benefits from the ideal titanium grade. Connect with our experts to find the perfect solution for your specific needs.

Get Expert Titanium AdviceFrequently Asked Questions about Titanium Bar Grades

What does "commercially pure" mean for titanium?

Commercially pure (CP) titanium refers to unalloyed titanium. It contains trace amounts of other elements. These elements are not intentionally added. They are residual impurities. CP grades are categorized from Grade 1 to Grade 4. Higher numbers indicate slightly higher strength. This comes with a small reduction in ductility.

Is Grade 5 titanium stronger than Grade 2?

Yes, Grade 5 titanium (Ti-6Al-4V) is significantly stronger than Grade 2. Grade 5 is an alloy. It contains aluminum and vanadium. These elements provide much higher tensile and yield strength. Grade 2 is commercially pure. It offers moderate strength but superior ductility and formability.

Can titanium grades be welded together?

Welding titanium requires specific techniques. It needs an inert gas atmosphere. This prevents contamination. Commercially pure grades like Grade 2 are generally easier to weld. Grade 5 can also be welded. However, it requires more stringent control. Welding dissimilar titanium grades is possible. It requires expert knowledge to maintain joint integrity.

What are the main applications for Grade 23 titanium?

Grade 23 titanium, also known as Ti-6Al-4V ELI (Extra-Low Interstitial), is a high-purity version of Grade 5. It offers enhanced ductility and fracture toughness. Its primary applications are in medical implants. This includes surgical devices and orthopedic components. It is also used in demanding aerospace applications where fatigue resistance is crucial.