Navigating the complex landscape of global titanium bar sourcing demands precision. B2B procurement professionals, manufacturers, and engineers face significant challenges. These include identifying reliable suppliers, ensuring material quality, and streamlining intricate supply chains.

This guide provides critical insights. It helps evaluate and partner with the most dependable industrial-grade titanium bar suppliers worldwide. The focus remains on achieving precision, ensuring compliance, and optimizing supply chain efficiency.

Securing high-quality industrial titanium bars is paramount. It directly impacts product performance and project success. This resource simplifies the procurement process for demanding applications.

Understanding Industrial-Grade Titanium Bars

Industrial-grade titanium bars are fundamental in advanced engineering. They are critical for numerous manufacturing applications. Delving into their characteristics reveals their widespread importance.

What is Industrial Titanium and Why is it Essential?

Industrial-grade titanium is a metallic element known for its unique properties. These properties make it indispensable across high-performance sectors. It boasts an exceptional strength-to-weight ratio. It also offers superior corrosion resistance.

Furthermore, its biocompatibility is highly valued. These attributes ensure reliability in demanding environments.

Industrial-Grade Titanium: Refers to titanium and its alloys specifically engineered for demanding industrial applications, characterized by high strength, low density, excellent corrosion resistance, and often biocompatibility.

These qualities are vital in aerospace, medical, and marine industries. They ensure component longevity and structural integrity.

Key Titanium Grades and Their Applications

Various titanium grades serve distinct purposes. Commercially pure (CP) grades, like Grade 1 and Grade 2, offer excellent ductility. They are also known for their formability and corrosion resistance.

Alloys, such as Grade 5 (Ti-6Al-4V) and Grade 23 (Ti-6Al-4V ELI), provide significantly higher strength. They maintain good fracture toughness. These alloys are crucial in critical applications.

| Titanium Grade | Key Characteristics | Primary Applications |

|---|---|---|

| Grade 1 (CP Titanium) | Highest ductility, excellent corrosion resistance, lowest strength. | Chemical processing, desalination plants, architectural components. |

| Grade 2 (CP Titanium) | Good balance of strength, ductility, and corrosion resistance. | Heat exchangers, power generation, general industrial applications. |

| Grade 5 (Ti-6Al-4V) | High strength, good fatigue resistance, widely used alloy. | Aerospace components, marine parts, sports equipment. |

| Grade 23 (Ti-6Al-4V ELI) | Extra Low Interstitials (ELI), enhanced toughness, biocompatible. | Medical implants, surgical instruments, orthopedic devices. |

For more detailed information on specific grades and their suitability, China Titanium Factory offers comprehensive product specifications.

Navigating the Global Landscape of Titanium Bar Sourcing

Sourcing titanium bars globally requires a strategic approach. It involves identifying reputable international suppliers. It also demands stringent quality assurance and efficient logistics. This section explores key considerations for B2B procurement.

Identifying Top International Titanium Suppliers

Researching leading global manufacturers is paramount. Assess their market presence and production capabilities. A supplier's reputation for reliability is also critical. Look for established companies with a strong track record.

Platforms like Statista provide valuable market data. They help identify key players and market trends. Partnering with a proven entity, such as China Titanium Factory, ensures access to quality products and expertise.

Essential Quality Standards and Certifications

Adherence to international quality standards is non-negotiable. These standards ensure compliance, traceability, and consistent performance. Key certifications include ASTM (American Society for Testing and Materials) and AMS (Aerospace Material Specifications).

ISO 9001 and AS9100 certifications demonstrate robust quality management systems. Requesting comprehensive material certifications is crucial. This includes Mill Test Reports (MTRs) for full traceability.

Mill Test Report (MTR): A document provided by the manufacturer that certifies the material's chemical and mechanical properties meet specific standards and specifications, detailing melt number, heat treatment, and test results.

Verify that suppliers provide detailed documentation. This confirms material integrity and origin.

Streamlining Global Supply Chain Logistics

Efficient logistics are vital for international procurement. Understanding international shipping regulations is key. Customs procedures must be navigated expertly. Effective inventory management strategies prevent delays and reduce costs.

Collaborate with suppliers offering optimized logistics solutions. This minimizes transit times and ensures timely delivery. Consulting with experienced suppliers can simplify these complex processes.

Technical Specifications and Performance of Titanium Bars

Precise material selection relies on in-depth technical data. This includes detailed specifications and material properties. Analytical tools aid in making informed decisions. This section provides critical technical resources.

Detailed Titanium Bar Forms, Sizes, and Finishes

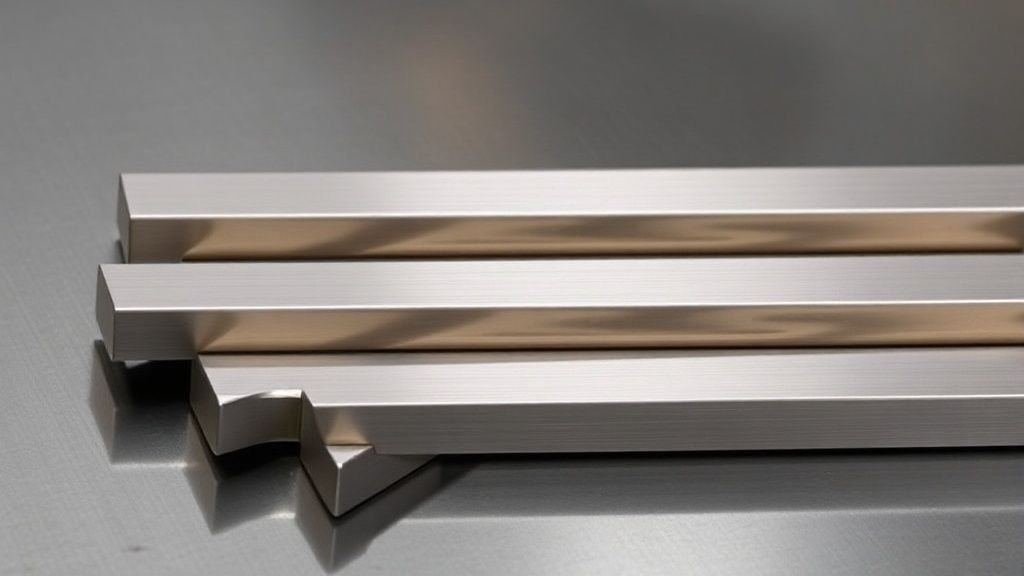

Industrial titanium bars come in various forms. These include round, square, and hexagonal shapes. Standard sizes are available, alongside custom dimensions. Surface finishes also vary, from as-rolled to polished.

These characteristics impact suitability for manufacturing processes. They also affect end-use applications. Selecting the correct form and finish is crucial for optimal performance.

Mechanical Properties and Metallurgical Analysis

Understanding mechanical properties is essential. Key parameters include tensile strength, yield strength, and hardness. Fatigue resistance is also a critical consideration. These properties dictate material behavior under stress.

Metallurgical analysis ensures product integrity. Detailed data sheets, including Material Safety Data Sheets (MSDS), provide crucial information. Material test reports offer verifiable proof of compliance.

The ASM International provides extensive resources on titanium metallurgy. This ensures engineers have the data needed for critical designs.

Material Calculators and Comparison Tools for Optimal Selection

Interactive online tools simplify material selection. They allow comparison of different titanium grades. These tools calculate material properties accurately. This optimizes material choice for specific project requirements.

Such tools help meet precise performance criteria. Utilizing these resources streamlines the design and procurement phases. They empower engineers to make data-driven decisions.

Vetting and Partnering with Reliable Titanium Suppliers

Establishing best practices for supplier evaluation is paramount. This mitigates risks and fosters long-term relationships. Transparency in the global titanium market is key to sustainable partnerships.

Comprehensive Supplier Evaluation Criteria

Thorough evaluation of potential titanium suppliers is critical. Assess their manufacturing capabilities and quality control processes. Production capacity and lead times are also important factors. Evaluate customer service responsiveness and technical support.

A holistic approach ensures a capable and reliable partner. This due diligence minimizes future supply chain issues. It guarantees consistent material quality.

Auditing Best Practices and Risk Management in Global Sourcing

Conduct effective supplier audits routinely. Assess financial stability to prevent disruptions. Implement robust risk management protocols. These safeguard against supply chain interruptions.

They also ensure consistent material quality. Proactive risk assessment builds supply chain resilience. This protects critical projects and production schedules.

Building Long-Term Supplier Relationships and Transparent RFQ Processes

Clear communication fosters collaborative partnerships. Streamlined and transparent Request for Quote (RFQ) processes are essential. These ensure fair pricing and sustainable supply. Long-term relationships benefit both parties.

They lead to better service and consistent material availability. Engaging with reputable suppliers early builds trust and efficiency.

Sustainability and Ethical Sourcing in the Titanium Industry

Responsible practices are increasingly important. The titanium supply chain must prioritize environmental impact. Corporate social responsibility (CSR) guides ethical sourcing. This section addresses these critical considerations.

Responsible Practices in Titanium Production

Commitment to sustainable sourcing is vital. Minimizing the environmental footprint is a key objective. Adherence to CSR standards throughout the supply chain is expected. This includes responsible mining and processing.

Suppliers should demonstrate efforts in waste reduction. They must also ensure energy efficiency. Ethical labor practices are equally important. For more on industry-wide efforts, refer to the International Titanium Association.

Market Insights and Future Trends in Titanium Bars

Analyzing current market dynamics is crucial. Technological advancements shape the industry. Future demand drivers inform strategic planning. This section explores the evolving landscape of industrial titanium bars.

Emerging Technologies and Demand Drivers

The titanium market is influenced by innovation. Additive manufacturing (3D printing) uses titanium extensively. This technology is creating new possibilities. Demand from aerospace, medical, and renewable energy sectors continues to grow.

Lightweighting initiatives in automotive also drive demand. These trends indicate a robust future for industrial titanium. Staying informed on these advancements is key for procurement professionals.

Success Stories and Client Testimonials

Real-world applications showcase titanium's impact. Testimonials from satisfied clients highlight successful partnerships. These stories demonstrate the tangible benefits of reliable global sourcing.

Real-World Applications and Partnership Highlights

Many critical industrial projects rely on quality titanium. For instance, a leading aerospace manufacturer sourced Grade 5 titanium bars. These were for crucial airframe components. China Titanium Factory provided certified materials with stringent quality control. This ensured compliance and timely delivery.

Another example involves a medical device company. They required Grade 23 ELI titanium for biocompatible implants. Their partnership with a trusted supplier ensured material purity and traceability. This allowed them to meet strict regulatory requirements.

Frequently Asked Questions (FAQs) about Titanium Bar Sourcing

This section addresses common questions. It covers technical, logistical, and procurement-related queries. These focus on industrial-grade titanium bars and global sourcing strategies.

Common Technical and Logistical Queries

What is the typical lead time for custom titanium bar orders?

Lead times vary based on grade, size, and order volume. Standard grades might ship in 4-6 weeks. Custom specifications or large quantities can extend to 8-12 weeks or more. Always confirm with your supplier.

How are titanium bars typically packaged for international shipping?

Titanium bars are often packaged in wooden crates or bundles. They are wrapped for protection against moisture and damage. Special care is taken for polished or precision-machined bars. This prevents surface imperfections during transit.

What is the minimum order quantity (MOQ) for industrial titanium bars?

MOQs depend on the supplier and specific product. Some suppliers offer smaller quantities for specialized grades. Larger, standard grades might have higher MOQs. Discuss your needs with your chosen supplier.

Can suppliers provide material certifications for every shipment?

Yes, reputable suppliers always provide full material certifications. These include Mill Test Reports (MTRs) with each shipment. This ensures complete traceability and compliance. Always request these documents.

Secure Your High-Performance Titanium Bars Today

Partner with an industry leader for unparalleled quality and reliability. China Titanium Factory specializes in industrial-grade titanium bars, meeting the most demanding specifications for aerospace, medical, and advanced manufacturing. Experience seamless global procurement and superior material performance.

Request a Quote Now