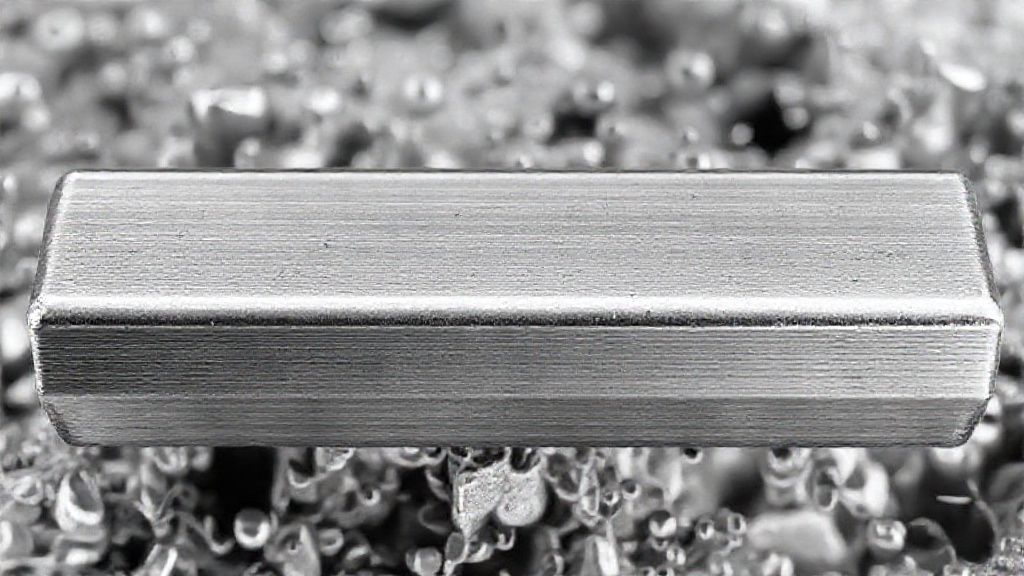

Introduction: Mastering Titanium Bar Machining and Fabrication

Machining and fabricating titanium bars are critical processes. They are essential for producing high-performance components. These components serve demanding applications across various industries.

Titanium's exceptional strength-to-weight ratio and corrosion resistance make it invaluable. However, its unique material properties present significant manufacturing challenges. This guide offers in-depth insights. It covers the technical intricacies of processing titanium bars. The focus is on precision and reliability.

Engineers and manufacturing professionals will find this resource invaluable. It details properties, challenges, and advanced techniques. For a reliable source of high-quality titanium materials, consider China Titanium Factory.

Understanding Titanium Bars: Properties and Applications

Titanium bars are distinguished by a unique combination of properties. These attributes make them ideal for demanding environments. Key characteristics include high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

The modulus of elasticity for titanium is approximately half that of steel. This allows for greater elastic deformation. Its melting point is around 1,668 °C (3,034 °F). This provides superior high-temperature performance compared to many other metals.

Several titanium grades are widely used. Grade 2 (Commercially Pure Titanium) offers good ductility and formability. Grade 5 (Ti-6Al-4V) is an alpha-beta alloy. It provides significantly higher strength and toughness. It is the most common aerospace alloy. Other grades, like Grade 7 (Ti-0.2Pd), enhance corrosion resistance further. These are crucial for specific chemical processing applications. You can explore a wide range of titanium bar products at China Titanium Factory.

Applications span diverse sectors. Aerospace utilizes titanium for airframes, engine components, and landing gear. Its lightweight nature and strength are critical. Medical implants, such as orthopedic devices and dental prosthetics, benefit from its biocompatibility. Marine industries leverage its corrosion resistance in saltwater environments. Chemical processing plants use titanium for heat exchangers and piping. This is due to its inertness to aggressive chemicals. For detailed specifications on various titanium grades, consult resources like AZoM's Titanium Properties database.

Navigating the Challenges of Machining Titanium

Machining titanium presents unique difficulties. These stem from its inherent material characteristics. Understanding these challenges is crucial for successful processing.

High Strength and Low Thermal Conductivity

Titanium alloys possess high strength at elevated temperatures. This leads to increased cutting forces during machining. Its low thermal conductivity is a significant issue. Heat generated during cutting does not dissipate easily. It concentrates at the tool-chip interface. This causes rapid tool wear and premature tool failure.

Chemical Reactivity and Work Hardening

Titanium is chemically reactive with many tool materials. This reactivity increases at high temperatures. It promotes adhesion and diffusion wear on cutting tools. Furthermore, titanium exhibits a strong tendency to work harden. This means the material becomes harder as it is deformed. This makes subsequent cuts more difficult. It can also lead to poor surface finish.

Chip Control and Vibration

Titanium chips are typically tough and stringy. They can easily entangle around the tool or workpiece. This impacts chip evacuation and can damage the surface finish. The material's low modulus of elasticity also contributes to vibration. This can result in chatter marks and reduced tool life. Proper fixturing is essential to mitigate these issues.

Precision Machining Techniques for Titanium Bars

Overcoming titanium's machining challenges requires specialized approaches. Optimal parameters, tool materials, and cooling strategies are vital. These ensure precision and efficiency.

Tool Material and Geometry Selection

Carbide tools are generally preferred for titanium machining. Specifically, uncoated or PVD-coated carbide grades work well. PVD coatings like TiAlN offer good wear resistance. Tool geometry is critical. Use sharp cutting edges with positive rake angles. This reduces cutting forces. A larger nose radius enhances edge strength and improves surface finish. Maintain sufficient chip space to prevent chip recutting.

Optimal Cutting Parameters

Low cutting speeds are recommended for titanium. This minimizes heat generation. Maintain a moderate feed rate to ensure proper chip formation. A sufficient depth of cut is also important. This avoids rubbing and work hardening. Consult tool manufacturer guidelines for specific recommendations. These vary based on grade and operation.

| Operation | Cutting Speed (SFM/m/min) | Feed Rate (IPR/mm/rev) | Depth of Cut (Inches/mm) |

|---|---|---|---|

| Turning | 100-250 / 30-75 | 0.005-0.015 / 0.13-0.38 | 0.050-0.200 / 1.27-5.08 |

| Milling | 150-300 / 45-90 | 0.003-0.008 / 0.08-0.20 per tooth | 0.050-0.150 / 1.27-3.81 radial |

| Drilling | 50-150 / 15-45 | 0.002-0.006 / 0.05-0.15 | Full diameter |

Cooling and Lubrication

Effective cooling is paramount. Flood coolants are widely used. High-pressure coolant delivery systems are even better. They penetrate the cutting zone more effectively. This reduces heat and aids chip evacuation. Water-soluble oils or synthetic coolants are common choices. They prevent chemical reactions between the tool and workpiece. For specialized titanium machining services, expertise in these areas is crucial.

Expert Fabrication Methods for Titanium Bars

Fabricating titanium bars involves various processes. These include cutting, forming, and joining. Each method requires specific considerations due to titanium's properties.

Cutting Titanium Bars

Traditional methods like sawing are possible. However, they require slow speeds and ample coolant. Abrasive cutting can also be effective. Waterjet cutting is an excellent non-thermal option. It produces clean cuts with minimal heat-affected zones. Laser cutting is suitable for thinner sections. It requires careful parameter control to prevent oxidation.

Forming and Bending Titanium

Titanium has limited cold formability compared to steel. Its high yield strength and low ductility pose challenges. Hot forming is often preferred. This reduces springback and prevents cracking. Temperatures typically range from 600-800°C. Specialized tooling and controlled atmospheres may be necessary. For custom shapes, custom titanium manufacturing processes are often employed.

Welding Titanium Bars

Welding titanium demands strict atmospheric control. Titanium readily reacts with oxygen, nitrogen, and hydrogen at elevated temperatures. This leads to embrittlement. Gas Tungsten Arc Welding (GTAW or TIG) is the most common method. It uses an inert gas shield (argon or helium). Electron Beam Welding (EBW) and Laser Beam Welding (LBW) also provide high-quality welds. These are performed in vacuum or inert gas environments. Proper joint preparation and post-weld cleaning are crucial. Learn more about titanium welding from the American Welding Society.

Ensuring Quality and Safety in Titanium Processing

Achieving high-quality results in titanium processing requires meticulous attention. Safety protocols are equally important. Both contribute to efficient and reliable manufacturing.

Surface Finish and Integrity

Poor surface finish can compromise fatigue life. It can also reduce corrosion resistance. Maintain sharp tools and optimal cutting parameters. This minimizes surface defects. Post-processing steps like polishing or passivation may be necessary. These enhance appearance and improve corrosion performance. Adherence to strict quality control standards is essential.

Chip Control and Housekeeping

Effective chip management prevents re-cutting and tool damage. Use chip breakers where possible. Ensure consistent coolant flow for chip evacuation. Titanium chips can be pyrophoric. They can ignite if finely divided and exposed to sufficient heat. Proper chip collection and disposal are critical. Store chips in sealed, non-combustible containers. Avoid mixing with other metal chips.

Safety Guidelines

Machining titanium generates fine dust and chips. These pose fire and explosion risks. Use appropriate personal protective equipment (PPE). This includes eye protection and flame-resistant clothing. Ensure adequate ventilation to minimize dust accumulation. Have Class D fire extinguishers readily available. These are designed for combustible metals. Never use water on burning titanium. It can intensify the fire.

Real-World Applications and Case Studies

The unique properties of machined and fabricated titanium bars drive their adoption. They are crucial across numerous high-stakes industries. These examples highlight titanium's versatility and reliability.

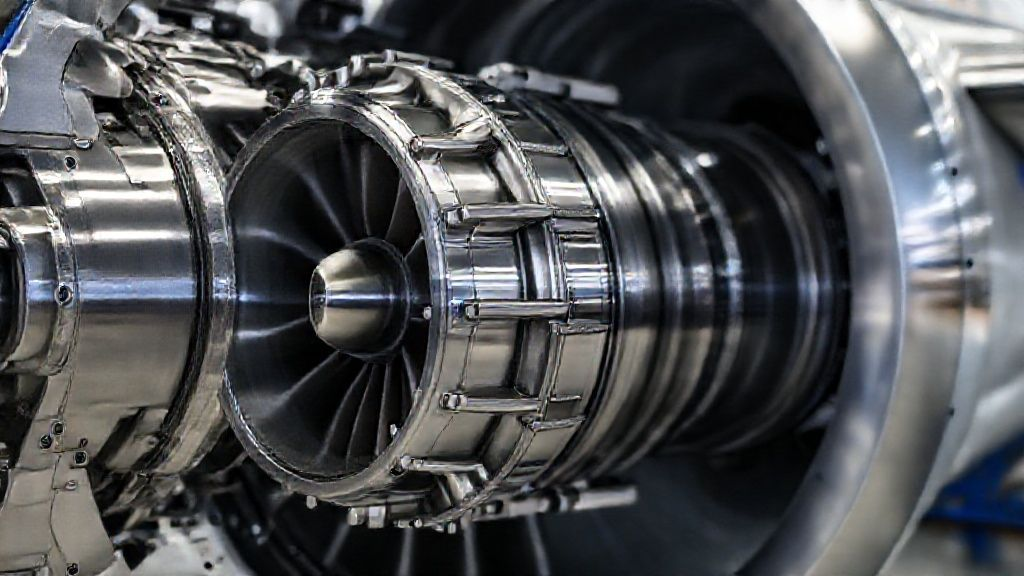

Aerospace Components

Titanium bars are extensively machined for aircraft structural components. These include landing gear, engine mounts, and fasteners. Boeing's 787 Dreamliner uses a significant amount of titanium. This reduces overall weight and improves fuel efficiency. Precision machining ensures critical tolerances. It guarantees the integrity of these flight-critical parts.

Medical Implants

In the medical field, titanium's biocompatibility is paramount. Fabricated titanium bars become orthopedic implants. Examples include hip and knee replacements. They also form surgical instruments and dental implants. The ability to precisely machine complex geometries is essential. This ensures proper fit and function within the human body. Stringent quality standards apply to all medical-grade titanium products.

Automotive and Motorsports

High-performance automotive applications utilize titanium. These include connecting rods, valves, and exhaust systems. Its lightweight nature reduces inertia. This improves engine responsiveness and fuel economy. Fabrication techniques like welding are critical here. They create strong, durable structures for extreme conditions.

Troubleshooting Common Issues in Titanium Processing

Even with best practices, issues can arise. Effective troubleshooting minimizes downtime. It also ensures consistent product quality.

Rapid Tool Wear

If tools wear quickly, revisit cutting parameters. Reduce cutting speed. Increase feed rate slightly to ensure proper chip load. Check coolant delivery. Ensure it reaches the cutting zone effectively. Consider alternative tool coatings or geometries. Ensure tool material is optimized for titanium.

Poor Surface Finish

Chatter marks or rough surfaces indicate issues. Increase machine rigidity. Check workpiece clamping. Ensure tools are sharp and free from buildup. A smaller nose radius or higher cutting speed (within limits) might help. Adjust feed rate for finer finishes. Ensure consistent and clean coolant supply.

Chip Control Problems

Long, stringy chips can cause issues. Increase feed rate slightly. This can create thicker, more manageable chips. Use tools with effective chip breakers. Optimize coolant flow to flush chips away. Ensure sufficient chip evacuation space in the tooling setup.

Frequently Asked Questions About Titanium Bar Processing

Q1: What is the best coolant for machining titanium?

A1: Water-soluble synthetic or semi-synthetic coolants are generally recommended. They provide good lubrication and heat dissipation. High-pressure coolant delivery is crucial for effective results. It helps penetrate the cutting zone and flush chips.

Q2: Why is titanium difficult to machine?

A2: Titanium is difficult due to its high strength, low thermal conductivity, and chemical reactivity. It also has a strong tendency to work harden. These properties lead to rapid tool wear and heat buildup.

Q3: Can titanium be cold formed?

A3: Cold forming titanium is possible but challenging. It has limited ductility and high springback. Hot forming is often preferred for complex shapes. This reduces stresses and prevents cracking.

Q4: What are the safety concerns when machining titanium?

A4: Fine titanium dust and chips can be pyrophoric. They pose fire and explosion risks. Proper ventilation, chip management, and Class D fire extinguishers are essential. Never use water on burning titanium.

Q5: How can I prevent tool chatter when machining titanium?

A5: To prevent chatter, ensure maximum rigidity in the setup. Use short tool overhangs. Optimize cutting parameters to avoid resonant frequencies. Employ vibration-dampening tool holders. Proper workpiece clamping is also critical.

Elevate Your Projects with Premium Titanium Bars

Mastering titanium processing can unlock immense potential. For your next critical application, partner with a trusted supplier. Contact China Titanium Factory today. Explore our extensive selection of high-quality titanium bars. Benefit from our expertise in precision manufacturing. Ensure superior performance and reliability for your demanding projects.