Unlocking Potential: An Introduction to Titanium Plate

Titanium plate represents a critical material in modern engineering. Its unique properties address challenges across diverse industries. This guide explores its extensive applications and inherent advantages.

Understanding titanium plate is essential for engineers and manufacturers. It offers solutions where traditional materials fail. Its significance continues to grow in demanding environments.

The Core Strengths: Unique Properties and Advantages of Titanium Plate

Titanium plate possesses an exceptional combination of properties. These attributes make it highly sought after. They enable its use in critical, high-performance applications.

Key advantages include its remarkable strength-to-weight ratio. It also offers unparalleled corrosion resistance. Biocompatibility and high-temperature performance are further benefits.

Strength-to-Weight Ratio: The material's tensile strength divided by its density. Titanium alloys excel in this metric, offering robust performance with minimal mass.

Titanium's passive oxide layer provides superior corrosion resistance. This is particularly true in chloride-rich environments. Its non-toxic nature allows for medical applications. High melting points ensure stability at elevated temperatures. These characteristics validate its status as a premier engineering material.

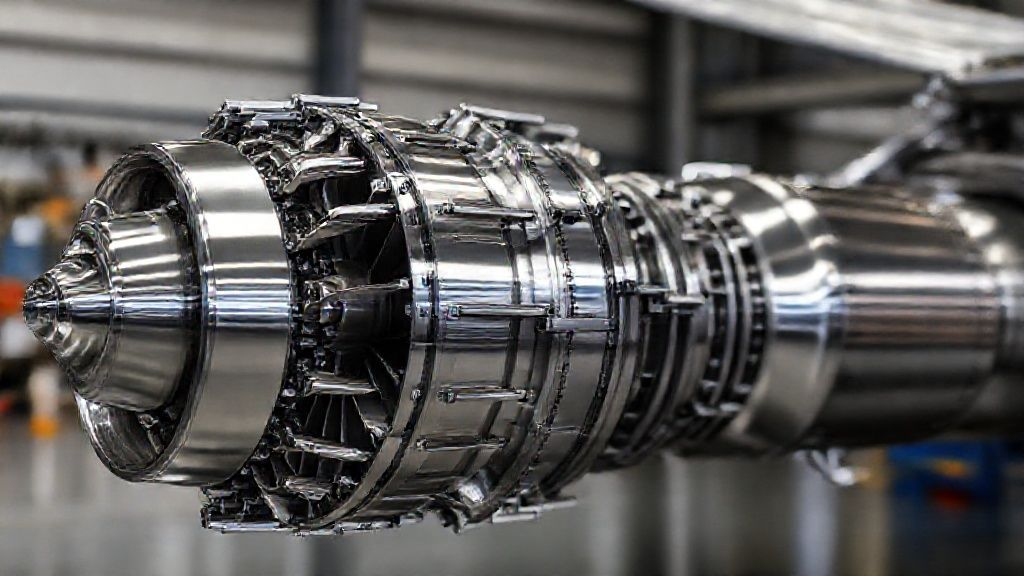

The aerospace sector relies heavily on titanium plate. Its lightweight nature is crucial for fuel efficiency. Its strength ensures structural integrity under extreme conditions.

Applications include aircraft frames, landing gear, and engine components. It is also used in fasteners and hydraulic systems. Titanium's performance in high-stress, high-temperature environments is unmatched. Leading manufacturers frequently specify titanium alloys for critical parts. These materials meet stringent aviation standards.

Further information on specialized fabrication for aerospace components can be found at China Titanium Factory's services page.

Medical and Biomedical: The Biocompatible Choice for Human Health

Titanium plate is a cornerstone in medical and biomedical applications. Its outstanding biocompatibility is key. It does not react adversely with bodily fluids or tissues.

This makes it ideal for surgical implants like joint replacements. It is also used in dental implants and prosthetic devices. The material's durability ensures long-term performance within the human body. Its resistance to corrosion prevents adverse reactions. This property is critical for patient safety and implant longevity.

The National Center for Biotechnology Information (NCBI) offers extensive research on titanium's biocompatibility.

Marine and Offshore: Defying the Depths and Corrosive Waters

Marine and offshore environments are extremely harsh. Saltwater and chlorides cause rapid corrosion. Titanium plate offers exceptional resistance to these conditions.

It is used in submersible components and shipbuilding. Heat exchangers for saltwater cooling systems also benefit. Its durability ensures long operational life in deep-sea applications. This includes components for oil and gas platforms. Titanium withstands the relentless corrosive forces of the ocean.

Discover more about specialized titanium products suitable for marine use at China Titanium Factory's product catalog.

Chemical Processing Industry (CPI): Resilience in Aggressive Environments

The Chemical Processing Industry (CPI) demands materials of high resilience. Equipment must withstand highly corrosive media. Titanium plate consistently performs well in such aggressive settings.

Applications include tanks, pressure vessels, and piping systems. It is also vital for heat exchangers handling strong acids and bases. Titanium ensures operational integrity and safety. Its resistance prevents costly failures and downtime. This makes it a preferred choice for critical infrastructure.

For specific solutions in chemical processing, China Titanium Factory's applications page provides further insights.

General Industrial and Manufacturing: Versatility Beyond Specialized Fields

Titanium plate's utility extends beyond highly specialized sectors. Its properties enhance performance in general industrial applications. This includes a wide range of manufacturing processes.

It is found in automotive parts requiring strength and lightness. Sporting goods, like golf clubs and bicycle frames, use it. Consumer electronics benefit from its durability. Architectural designs incorporate it for aesthetic appeal and longevity. Titanium's versatility demonstrates its broad applicability.

Technical Specifications and Grades: Selecting the Right Titanium Plate

Selecting the appropriate titanium plate grade is paramount. Each grade offers specific compositions and mechanical properties. These are tailored for different application requirements.

Common grades include Grade 1 (commercially pure, soft), Grade 2 (most common, good balance), Grade 5 (Ti-6Al-4V, aerospace standard), Grade 7 (corrosion-resistant with palladium), and Grade 12 (high strength, good weldability). Adherence to industry standards like ASTM and ISO ensures quality and performance.

ASTM Standards: A globally recognized set of technical standards for materials, products, systems, and services. For titanium, ASTM B265 specifies plate, sheet, and strip.

Understanding these specifications is crucial for procurement specialists. It ensures the material meets design and operational demands. Detailed material selection guides are available from reputable suppliers like China Titanium Factory.

| Grade | Composition | Key Property | Typical Applications |

|---|---|---|---|

| Grade 1 | Commercially Pure (CP) | High ductility, excellent formability | Chemical processing, desalination, architectural |

| Grade 2 | Commercially Pure (CP) | Good strength, excellent corrosion resistance | Heat exchangers, general industrial, marine |

| Grade 5 (Ti-6Al-4V) | Titanium-6% Aluminum-4% Vanadium | High strength, lightweight, good fatigue resistance | Aerospace, medical implants, high-performance automotive |

| Grade 7 | Titanium-0.15% Palladium | Superior corrosion resistance in reducing acids | Chemical processing, extreme corrosive environments |

| Grade 12 | Titanium-0.3% Molybdenum-0.8% Nickel | Good strength, excellent weldability, improved crevice corrosion resistance | Heat exchangers, vessels, piping systems |

Comparative Analysis: Titanium Plate vs. Alternative Materials

Engineers often evaluate titanium plate against other materials. Stainless steel, aluminum alloys, and nickel alloys are common alternatives. A detailed comparison reveals titanium's unique advantages.

Stainless steel offers good strength and corrosion resistance. However, titanium significantly outperforms it in aggressive chemical environments and saltwater. Aluminum alloys are lighter than titanium. Yet, they lack titanium's strength at elevated temperatures and its exceptional corrosion resistance.

Nickel alloys provide excellent high-temperature strength and corrosion resistance. They often come at a higher cost and density than titanium. Titanium's superior strength-to-weight ratio often makes it a more efficient choice. This is especially true where weight reduction is critical, such as in aerospace.

For comprehensive material data sheets, refer to resources like MatWeb, a leading online materials database.

Cost-Benefit Analysis: The Long-Term Value of Titanium Plate

The initial investment in titanium plate can be higher than other materials. However, a comprehensive cost-benefit analysis reveals significant long-term value. This material often delivers a strong return on investment (ROI).

Titanium's extended lifespan reduces replacement costs. Its corrosion resistance minimizes maintenance requirements. Enhanced operational efficiency results from its lightweight and durable nature. These factors contribute to lower total lifecycle costs. For example, in aerospace, reduced weight directly translates to fuel savings over the aircraft's operational life. In chemical processing, avoiding equipment failure prevents costly shutdowns.

Sustainability and Environmental Impact of Titanium Plate

The environmental profile of titanium plate is increasingly relevant. It plays a role in sustainable engineering practices. Titanium is a highly recyclable material.

Its lightweight properties contribute to reduced resource consumption. This is evident in fuel-efficient vehicles and aircraft. The material's durability also extends product lifespans. This reduces waste and the need for frequent replacements. Responsible sourcing and production practices further enhance its eco-friendly characteristics. The industry is committed to minimizing its environmental footprint.

Real-World Success: Detailed Case Studies of Titanium Plate in Action

Numerous case studies highlight titanium plate's impact. These examples demonstrate its problem-solving capabilities across industries. They showcase performance improvements and cost-effectiveness.

One notable case involves a chemical plant facing frequent failures of stainless steel heat exchangers. Switching to Grade 7 titanium plate dramatically extended their operational life. This reduced maintenance costs and downtime. In another instance, the use of Ti-6Al-4V (Grade 5) in a new aircraft design led to significant weight savings. This directly improved fuel efficiency and payload capacity. These cases prove titanium's tangible benefits.

The Aerospace Technology portal often features case studies on material innovations.

Frequently Asked Questions (FAQs) About Titanium Plate

What is titanium plate used for?

Titanium plate is used in aerospace components, medical implants, marine equipment, and chemical processing. Its applications extend to general industrial manufacturing and consumer goods. Its versatility comes from its unique properties.

What are the main advantages of titanium plate?

Its main advantages include an excellent strength-to-weight ratio, superior corrosion resistance, and biocompatibility. It also performs well at high temperatures. These benefits make it ideal for demanding applications.

Is titanium plate expensive?

The initial cost of titanium plate can be higher than other materials. However, its long-term value, due to extended lifespan and reduced maintenance, often provides a superior return on investment. Cost-effectiveness is assessed over the product's lifecycle.

What are the common grades of titanium plate?

Common grades include Commercially Pure (CP) Grades 1, 2, 3, and 4. Alloyed grades like Grade 5 (Ti-6Al-4V), Grade 7 (Ti-0.15Pd), and Grade 12 (Ti-0.3Mo-0.8Ni) are also widely used. Each grade has specific properties for distinct applications.

How does titanium plate compare to stainless steel?

Titanium plate offers a higher strength-to-weight ratio and superior corrosion resistance, especially in aggressive chloride environments. While stainless steel is more economical, titanium's performance benefits often justify its higher cost in critical applications requiring extreme durability and lightness.