What Are Titanium Plates and Why Are They Essential?

Titanium plates are flat sheets of titanium metal. They possess an exceptional strength-to-weight ratio. They also offer superior corrosion resistance. These unique properties make titanium indispensable. Various critical industries rely on it for high-performance applications.

The manufacturing of titanium plates is a complex process. It involves multiple stages. Each stage refines the material's properties. This ensures the final product meets stringent quality demands. Understanding this journey is crucial. It guarantees the integrity and reliability of titanium components.

The Comprehensive Titanium Plate Manufacturing Process

The journey from raw titanium ore to a finished plate is intricate. It involves a series of highly controlled steps. Precision and expertise are crucial at each stage. This ensures the production of high-quality material. The process begins with raw material selection. It concludes with final surface finishing.

Selecting Raw Materials: The Foundation of Quality Titanium Plates

The manufacturing process starts with titanium ore. Ilmenite and rutile are primary sources. These ores undergo chemical processing. This yields titanium tetrachloride (TiCl4). Further reduction processes then convert TiCl4 into titanium sponge. The Kroll process is a common method for this conversion. This method involves reducing TiCl4 with magnesium.

Purity is paramount at this initial stage. Contaminants can severely compromise the final product's properties. Strict quality control measures are implemented. These ensure the highest quality titanium sponge. This sponge forms the bedrock for all subsequent manufacturing steps.

Melting and Casting: Crafting Titanium Ingots

Titanium sponge is compacted and welded into electrodes. These electrodes are then melted. This occurs in specialized furnaces. Vacuum Arc Remelting (VAR) is a widely used technique. It melts the titanium in a vacuum environment. This minimizes oxygen and nitrogen pick-up. Electron Beam Cold Hearth Melting (EBCHM) is another advanced method. It offers even greater impurity removal. These processes produce high-quality titanium ingots. These ingots are free from harmful inclusions. Multiple melting cycles are often employed. This further enhances material homogeneity.

Vacuum Arc Remelting (VAR): A process where a consumable electrode made of compacted titanium sponge is melted by an electric arc in a vacuum chamber, consolidating it into a high-purity ingot.

Forging: Shaping the Future of Titanium

Ingots proceed to the forging stage. Here, mechanical force shapes them. Both open-die and closed-die forging methods are utilized. Forging refines the material's grain structure. It eliminates porosity. This improves the mechanical properties significantly. The internal structure becomes more uniform. This prepares the titanium for subsequent rolling operations. Precise temperature control is essential during forging. It prevents cracking and ensures optimal material flow.

Hot and Cold Rolling: Achieving Desired Dimensions and Properties

The forged titanium billets are then hot rolled. This reduces their thickness substantially. Hot rolling occurs above the material's recrystallization temperature. It allows for large deformations. This process also refines the grain structure further. After hot rolling, plates may undergo cold rolling. Cold rolling takes place at room temperature. It achieves precise dimensional tolerances. It also imparts a superior surface finish. Cold rolling enhances the material's strength and hardness. This is due to work hardening.

Hot Rolling: A metalworking process that occurs above the recrystallization temperature of the material, allowing for significant plastic deformation and grain refinement.

Heat Treatment: Optimizing Titanium's Performance

Heat treatment is a critical step. It tailors the final properties of titanium plates. Annealing is a common process. It relieves internal stresses. It also increases ductility. Solution treatment and aging are used for specific alloys. These treatments optimize strength and toughness. They also improve fatigue resistance. The exact heat treatment cycle depends on the titanium grade. It also depends on the intended application. Precise temperature and time controls are paramount.

For more details on specific heat treatment protocols, explore resources available at our comprehensive technical guides.

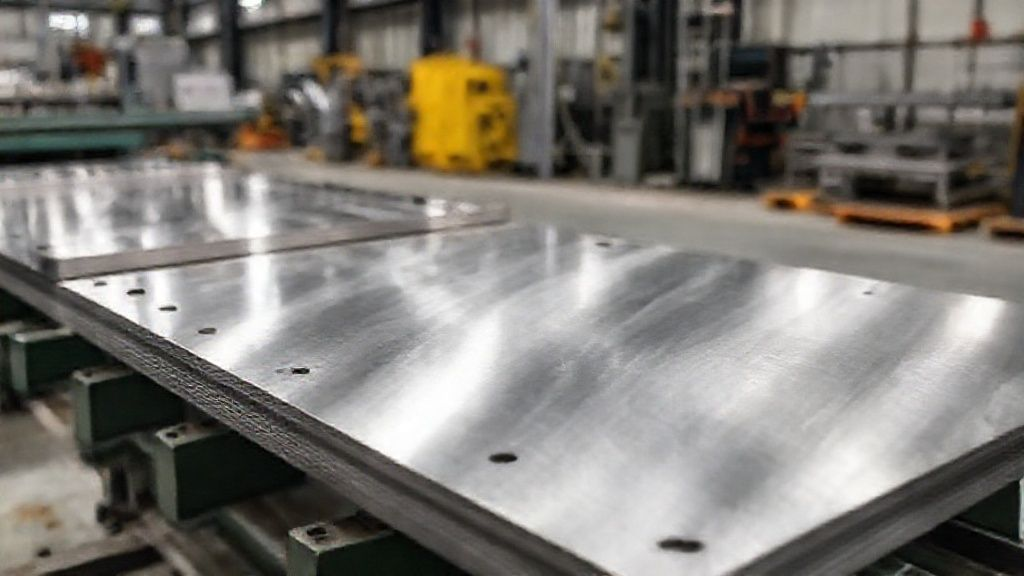

Surface Finishing: The Final Touch

The final stage involves surface finishing. This ensures the plate meets aesthetic and functional requirements. Pickling removes surface oxides and scale. This is achieved using acid solutions. Grinding provides precise thickness control. It also improves surface smoothness. Polishing further enhances the surface finish. Shot blasting can create a uniform, matte texture. These processes are vital. They prepare the titanium plate for its intended use. They also prevent potential surface defects from affecting performance.

Quality Assurance: Upholding Titanium Plate Standards

Manufacturing high-performance titanium plates demands stringent quality control. Every step, from raw material to final inspection, is critical. Adherence to international standards ensures reliability. It also guarantees performance in demanding applications. This section details the rigorous measures taken.

Navigating Key Titanium Plate Standards: ASTM, ISO, and AMS

Several organizations set standards for titanium products. ASTM International is a primary body. ASTM B265 specifies requirements for titanium and titanium alloy strip, sheet, and plate. ISO standards also define material properties. Aerospace Material Specifications (AMS) are crucial for aviation. ASTM B265 covers various grades and forms. These standards dictate chemical composition. They also specify mechanical properties. Adherence to these standards is non-negotiable. It ensures material suitability for critical applications.

For a deeper dive into these specifications, visit our dedicated quality standards page.

Chemical Composition: The Blueprint of Titanium Alloys

The precise chemical composition defines each titanium grade. Elements like aluminum, vanadium, and oxygen are critical. They impart specific mechanical and physical properties. Strict control over these elements is maintained. Impurity levels are also tightly regulated. Even trace amounts of certain elements can impact performance. Spectroscopic analysis verifies the composition. This ensures compliance with specified standards. This step is fundamental to material integrity.

Mechanical Properties Testing: Verifying Strength and Durability

After manufacturing, titanium plates undergo rigorous testing. Tensile testing measures ultimate tensile strength. It also determines yield strength and elongation. Hardness tests assess resistance to deformation. Impact tests evaluate toughness. These tests confirm the material's mechanical performance. They ensure it meets the design requirements. Certified laboratories perform these evaluations. This provides objective proof of quality.

Here is a table outlining typical mechanical properties for common titanium grades:

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Grade 1 (CP Ti) | 240 min | 170 min | 24 min |

| Grade 2 (CP Ti) | 345 min | 275 min | 20 min |

| Grade 5 (Ti-6Al-4V) | 895 min | 828 min | 10 min |

Non-Destructive Testing (NDT): Ensuring Flawless Plates

Non-Destructive Testing (NDT) methods are crucial. They detect internal and surface flaws without damaging the material. Ultrasonic testing identifies internal discontinuities. Eddy current testing detects surface and near-surface cracks. Radiographic inspection reveals internal defects. These techniques are vital for critical applications. They ensure the structural integrity of every plate. NDT provides an additional layer of assurance. It confirms material quality.

Non-Destructive Testing (NDT): A range of inspection techniques used to evaluate the properties of a material, component, or system without causing damage.

Dimensional Tolerances and Surface Integrity

Titanium plates must meet precise dimensional tolerances. This includes thickness, width, and length. Advanced measuring equipment verifies these dimensions. Surface integrity is equally important. Any surface defects, such as scratches or pits, can compromise performance. Visual inspection and specialized surface analysis tools are used. They confirm a flawless surface finish. This meticulous attention to detail ensures optimal functionality.

Titanium Plates in Action: Grades, Applications, and Innovations

Titanium's unique properties make it invaluable. It serves a vast array of applications. Different grades are tailored for specific needs. From aerospace to medical implants, titanium excels. The industry also constantly innovates. New technologies and sustainable practices are emerging.

Understanding Titanium Grades: From Pure to Alloyed

Titanium is available in various grades. Commercially Pure (CP) titanium includes Grades 1, 2, 3, and 4. Grade 1 is the softest and most ductile. Grade 2 is the most common for general industrial use. Alloyed titanium offers enhanced properties. Grade 5 (Ti-6Al-4V) is the most widely used alloy. It combines high strength with good corrosion resistance. Grade 7 contains palladium. This provides exceptional corrosion resistance in reducing acids. Grade 23 (Ti-6Al-4V ELI) is extra-low interstitial. It is ideal for medical implants.

Aerospace: Where Titanium Soars

The aerospace industry is a major consumer of titanium. Its high strength-to-weight ratio is critical. It reduces aircraft weight. This improves fuel efficiency. Components include airframe structures, landing gear, and engine parts. Fasteners and hydraulic systems also utilize titanium. Its superior fatigue life is another key advantage. Titanium alloys are essential for modern aircraft design.

Medical Implants: The Biocompatible Choice

Titanium is highly biocompatible. This means it is well-tolerated by the human body. It does not cause adverse reactions. This makes it ideal for medical implants. Applications include hip and knee replacements. Dental implants and surgical instruments also use titanium. Grade 23 (Ti-6Al-4V ELI) is particularly favored. Its excellent corrosion resistance in bodily fluids is crucial. It ensures long-term implant success.

Chemical Processing: Resisting the Harshest Environments

Titanium exhibits outstanding corrosion resistance. It withstands aggressive chemical environments. This makes it perfect for chemical processing equipment. Heat exchangers, tanks, and piping are common applications. It resists chlorides, acids, and other corrosive agents. This ensures operational safety and longevity. It reduces maintenance costs in harsh industrial settings.

Marine and Offshore: Conquering Saltwater Challenges

Saltwater is notoriously corrosive. Titanium's resistance to seawater is unparalleled. This makes it indispensable for marine and offshore industries. Submarine components, offshore platform structures, and desalination plants benefit. Heat exchangers in these environments rely on titanium. Its durability in saline conditions ensures extended service life. It minimizes costly repairs and replacements.

Emerging Technologies and Sustainable Practices in Titanium Manufacturing

The titanium industry is evolving. Additive manufacturing (3D printing) is gaining traction. It allows for complex geometries. It also reduces material waste. Electron Beam Melting (EBM) and Laser Powder Bed Fusion (LPBF) are examples. Efforts are also focused on sustainability. Advanced recycling techniques are being developed. They recover titanium from scrap. Energy-efficient processes are also being implemented. These initiatives aim for a greener manufacturing footprint.

Overcoming Hurdles: Common Challenges and Best Practices in Titanium Plate Production

Titanium plate manufacturing presents unique challenges. These range from material properties to process control. Addressing these hurdles ensures consistent quality. It also optimizes production efficiency. Implementing best practices is key. It mitigates risks and enhances outcomes.

Common Manufacturing Defects and How to Prevent Them

Defects can arise at various stages. Cracks may form during forging or rolling. Inclusions can occur during melting. Surface imperfections can result from improper finishing. Preventing these requires meticulous process control. Regular equipment maintenance is also vital. In-process inspection helps catch issues early. This reduces scrap rates and rework. Adhering to strict protocols minimizes defect occurrence.

Optimizing Efficiency and Cost-Effectiveness

Titanium is a premium material. Its manufacturing can be costly. Optimizing efficiency is therefore crucial. Strategies include reducing material waste. Enhancing yield rates also improves cost-effectiveness. Process automation can streamline operations. Advanced simulation tools predict material behavior. This minimizes trial and error. Continuous improvement initiatives are essential. They drive down costs without compromising quality.

Essential Glossary of Titanium Manufacturing Terms

Annealing: A heat treatment process that alters the microstructure of a material to increase ductility and reduce hardness.

Biocompatibility: The ability of a material to perform with an appropriate host response in a specific application.

Cold Rolling: A metalworking process performed below the recrystallization temperature, resulting in improved surface finish, dimensional accuracy, and increased strength.

Ductility: The ability of a material to deform plastically under tensile stress without fracturing.

Ingot: A mass of metal cast into a convenient shape for storage or transport, or for further processing.

Pickling: A metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust, or scale from ferrous metals, copper, and titanium alloys.

Titanium Sponge: A porous, brittle form of titanium produced by the reduction of titanium tetrachloride, serving as the primary feedstock for titanium melting.

Yield Strength: The stress at which a material begins to deform plastically (irreversibly).

Frequently Asked Questions About Titanium Plate Manufacturing

What makes titanium so difficult to machine?

Titanium presents several machining challenges. Its high strength and low thermal conductivity are primary factors. Heat concentrates at the cutting edge. This leads to rapid tool wear. Titanium also has a tendency to gall. This means it adheres to cutting tools. Specialized cutting tools and techniques are required. These include low cutting speeds and high feed rates. Abundant coolant use is also essential.

How does the manufacturing process affect titanium's properties?

Every stage of manufacturing profoundly impacts titanium's properties. Melting controls chemical purity. Forging refines grain structure. It enhances mechanical strength. Rolling influences dimensional accuracy. It also affects surface finish. Heat treatment optimizes ductility and stress relief. Each step is carefully controlled. It ensures the final product meets specific performance criteria. This holistic approach guarantees material integrity.

What are the main differences between hot and cold rolled titanium plates?

Hot rolling occurs at high temperatures. It primarily reduces bulk thickness. It also refines the grain structure. Hot rolled plates have a rougher surface finish. They offer good ductility. Cold rolling is done at room temperature. It provides precise dimensions. It also results in a superior surface finish. Cold rolled plates exhibit higher strength and hardness. This is due to strain hardening. The choice depends on desired final properties.

Is titanium plate manufacturing environmentally friendly?

Traditional titanium manufacturing is energy-intensive. It generates byproducts. However, the industry is moving towards sustainability. Companies are investing in cleaner processes. Recycling titanium scrap is increasing. Additive manufacturing reduces material waste. Efforts are ongoing to minimize environmental impact. The long lifespan of titanium products also contributes to sustainability. It reduces the need for frequent replacements.

Where can I find reliable titanium plate suppliers?

Finding reliable suppliers is crucial. Look for manufacturers with certifications. ISO 9001 and AS9100 are good indicators. Verify their adherence to industry standards. Check their testing capabilities. Experience in your specific application area is beneficial. Reputable suppliers provide comprehensive material certifications. For trusted sourcing, consider exploring our contact page for expert assistance.

The Future is Titanium: A Look Back and Forward

The manufacturing of titanium plates is a testament to engineering excellence. It transforms raw materials into high-performance components. These are vital for numerous advanced industries. From the meticulous selection of raw materials to rigorous quality checks, every step is crucial. This journey ensures that titanium plates meet the most demanding specifications.

As technology advances, so too will titanium manufacturing. Innovations in additive manufacturing and sustainable practices promise a more efficient future. The enduring properties of titanium ensure its continued relevance. It will remain a cornerstone material for critical applications worldwide. For more information on titanium products and services, visit our main website.

Need Expert Titanium Solutions?

Unlock the full potential of titanium for your next project. Our expertise in manufacturing and quality standards ensures you receive only the best.

Get a Custom Quote Today