Understanding Titanium Plates: An Essential Introduction

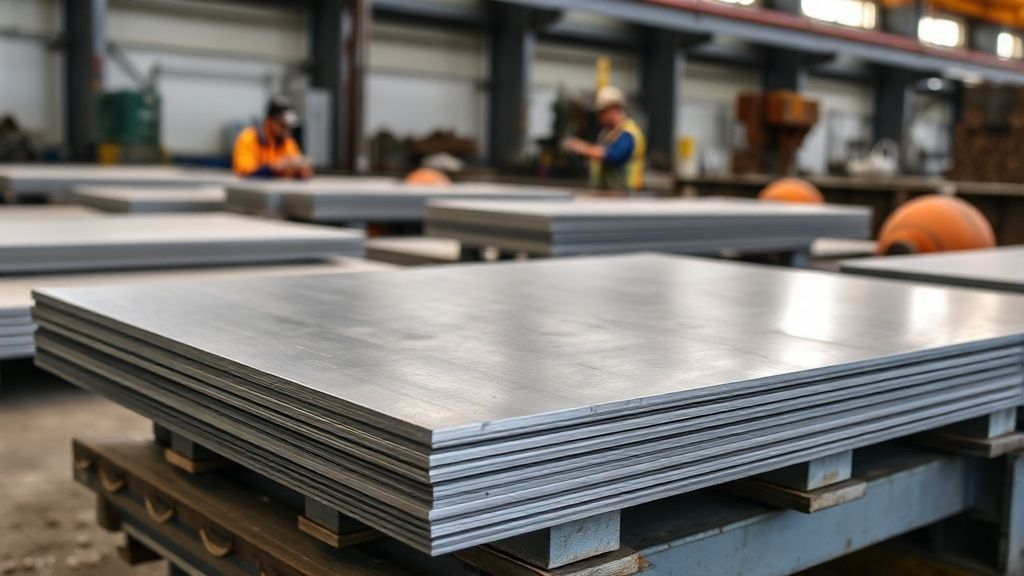

Titanium plates are flat sheets of titanium metal. They serve as foundational materials across many high-performance industries. These plates offer unique properties unmatched by other metals.

They are crucial in applications demanding extreme durability and reliability. This guide explores their specifications, fabrication, and critical role. It provides essential insights for engineers and specialists.

Titanium Plate: A form of titanium material typically supplied in flat, rectangular sheets. It possesses a high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, making it ideal for demanding industrial applications.

The Unrivaled Properties of Titanium: Why It Excels

Titanium's exceptional properties make it indispensable. Its high strength-to-weight ratio is a primary advantage. This allows for lighter yet robust components.

Corrosion resistance is another key attribute. Titanium withstands harsh environments, including saltwater and various chemicals. This extends product lifespan significantly.

Furthermore, titanium is highly biocompatible. This means it is non-toxic and compatible with biological tissue. It is therefore ideal for medical implants and prosthetics.

Its thermal properties also contribute to its versatility. Titanium maintains integrity at both high and low temperatures. This ensures stable performance in diverse conditions.

Decoding Titanium Plate Specifications: Standards and Grades

Selecting the correct titanium plate requires precise knowledge. Specifications define material composition and performance. Adhering to these standards ensures project success.

Engineers and procurement specialists rely on these details. They guarantee that materials meet strict application requirements. China Titanium Factory offers a comprehensive range of certified titanium products.

International Standards for Titanium Plates (ASTM, AMS)

International standards are vital for quality control. They ensure consistency and reliability worldwide. ASTM (American Society for Testing and Materials) is widely recognized.

AMS (Aerospace Material Specifications) governs aerospace applications. These standards specify chemical composition, mechanical properties, and testing methods. Understanding them is crucial for material procurement.

For instance, ASTM B265 covers titanium and titanium alloy strip, sheet, and plate. ASTM International provides detailed specifications. AMS standards, like AMS 4911, focus on specific aerospace-grade alloys.

These designations are critical for ensuring material integrity. They prevent costly failures in demanding environments.

Common Titanium Plate Grades and Their Applications

Titanium is available in various grades, each with distinct properties. Commercially Pure (CP) titanium grades are common. These include CP Grade 1, 2, 3, and 4.

CP Grade 1 is the softest and most ductile. It offers excellent corrosion resistance. Applications include chemical processing and marine components.

CP Grade 2 is the most widely used. It balances strength, ductility, and formability. It is found in heat exchangers and architectural structures.

CP Grade 5, also known as Ti-6Al-4V, is an alloy. It contains 6% aluminum and 4% vanadium. This grade offers exceptional strength and toughness.

Ti-6Al-4V is dominant in aerospace and medical implants. Its high strength-to-weight ratio is critical for these sectors. Other alloys, like Grade 7 (Ti-Pd), enhance corrosion resistance.

| Grade | Key Properties | Primary Applications |

|---|---|---|

| CP Grade 1 | Highest ductility, excellent corrosion resistance. | Chemical processing, desalination plants, medical devices. |

| CP Grade 2 | Good balance of strength, ductility, and formability. | Heat exchangers, architectural components, marine. |

| CP Grade 3 | Higher strength than Grade 2, good weldability. | Pressure vessels, structural components. |

| CP Grade 4 | Highest strength CP grade, limited formability. | Airframe components, surgical hardware. |

| Ti-6Al-4V (Grade 5) | Exceptional strength-to-weight, high toughness. | Aerospace, medical implants, automotive, sporting goods. |

Standard Dimensions and Thickness Ranges

Titanium plates are available in various standard dimensions. Thickness ranges typically from 0.1875 inches (4.76 mm) up to several inches. Widths and lengths also vary.

Common plate widths include 36, 48, and 60 inches. Standard lengths can extend to 96, 120, or 144 inches. Custom sizes are often available from specialist suppliers.

Selecting appropriate plate sizes minimizes waste and fabrication costs. Always consult with your supplier for specific stock availability. China Titanium Factory can assist with custom dimension requirements.

Mastering Custom Titanium Plate Fabrication: Techniques and Best Practices

Fabricating titanium requires specialized techniques. Its unique properties demand careful handling. Precision and expertise are paramount for successful outcomes.

This section details essential fabrication methods. It also covers best practices to ensure optimal results. Reliability and efficiency are key objectives.

Precision Cutting of Titanium Plates

Accurate cutting is the first step in fabrication. Several methods are effective for titanium. Each has distinct advantages and limitations.

Laser cutting offers high precision and narrow kerf. It is ideal for intricate shapes. However, it can induce heat-affected zones.

Waterjet cutting uses a high-pressure stream of water and abrasive. It creates clean cuts with no heat distortion. This makes it suitable for heat-sensitive applications.

Plasma cutting is faster for thicker plates. It is less precise than laser or waterjet. Mechanical sawing is also used for straight cuts on thicker stock.

Proper material preparation is crucial for all methods. Post-cut finishing may be required to remove burrs or oxides. Learn more about titanium cutting services.

Advanced Welding Techniques for Titanium

Welding titanium presents unique challenges. Titanium is highly reactive with atmospheric gases. Contamination can lead to brittle welds.

TIG (Tungsten Inert Gas) welding is common for titanium. It provides precise control and high-quality welds. Inert gas shielding (argon) is critical.

MIG (Metal Inert Gas) welding can be used for thicker sections. It offers higher deposition rates. Again, robust shielding is paramount.

Electron beam welding provides deep penetration and minimal distortion. This process occurs in a vacuum chamber. It ensures exceptional weld integrity.

Proper joint preparation and post-weld treatment are essential. These steps prevent contamination and maintain structural integrity. The American Welding Society (AWS) provides comprehensive standards for welding titanium and its alloys (Source: AWS).

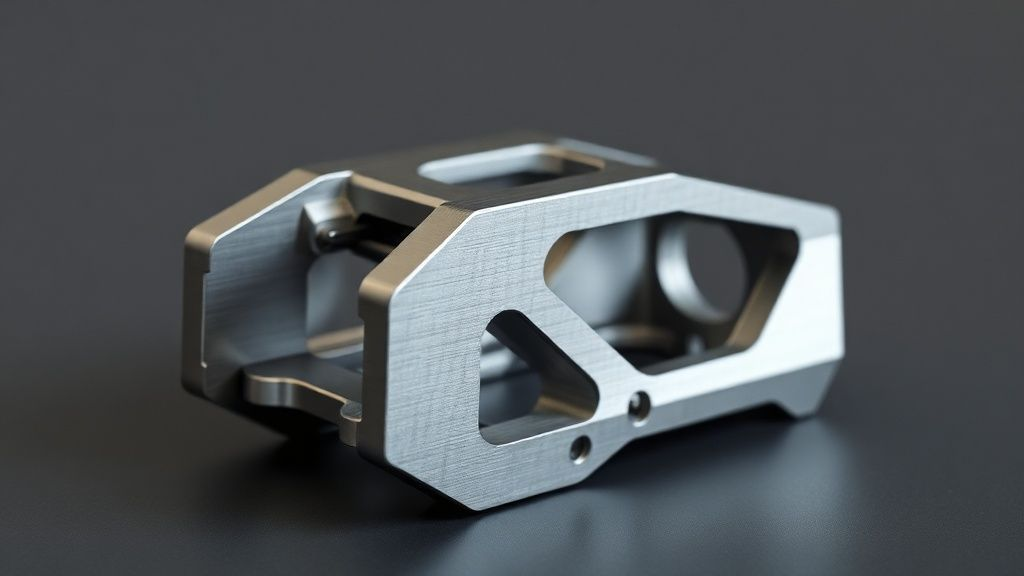

Machining Titanium: Best Practices for Optimal Results

Machining titanium requires specific approaches. Its low thermal conductivity and high strength cause challenges. Tool wear and heat generation are common issues.

Use sharp, robust cutting tools. Carbide tooling is often preferred. Maintain low cutting speeds and high feed rates.

Aggressive cooling strategies are vital. Flood coolants or high-pressure coolant systems dissipate heat effectively. This prevents work hardening and ensures a superior surface finish.

Achieving precise tolerances demands careful execution. Optimized machining parameters extend tool life. They also prevent material degradation.

Forming and Bending Titanium Plates

Forming titanium plates requires expertise. Titanium exhibits significant springback. This must be accounted for during bending operations.

Cold forming is suitable for lighter gauges and simpler bends. It offers good surface finish. However, it requires higher forming forces.

Hot forming is preferred for thicker plates or complex geometries. Heating titanium reduces its yield strength. This minimizes springback and allows for tighter bend radii.

Specialized tooling and careful process control are necessary. These ensure desired geometries without material degradation. Our expertise ensures consistent quality.

Achieving Superior Surface Finishes for Titanium

Surface finishing enhances titanium's properties. It improves aesthetics and corrosion resistance. It also prepares surfaces for further processing.

Polishing creates a smooth, reflective surface. It is often used for medical implants and decorative applications. Anodizing forms a protective oxide layer.

Anodizing can also produce vibrant colors. Blasting (e.g., grit or bead blasting) creates a matte finish. It can also improve adhesion for coatings.

Pickling involves chemical treatment. It removes surface contaminants and scale. This ensures a clean, reactive surface. Each method contributes to specific functional or aesthetic goals.

Real-World Impact: Titanium Plate Applications and Success Stories

Titanium plates are critical across many demanding industries. Their unique properties solve complex engineering challenges. They ensure reliability in harsh conditions.

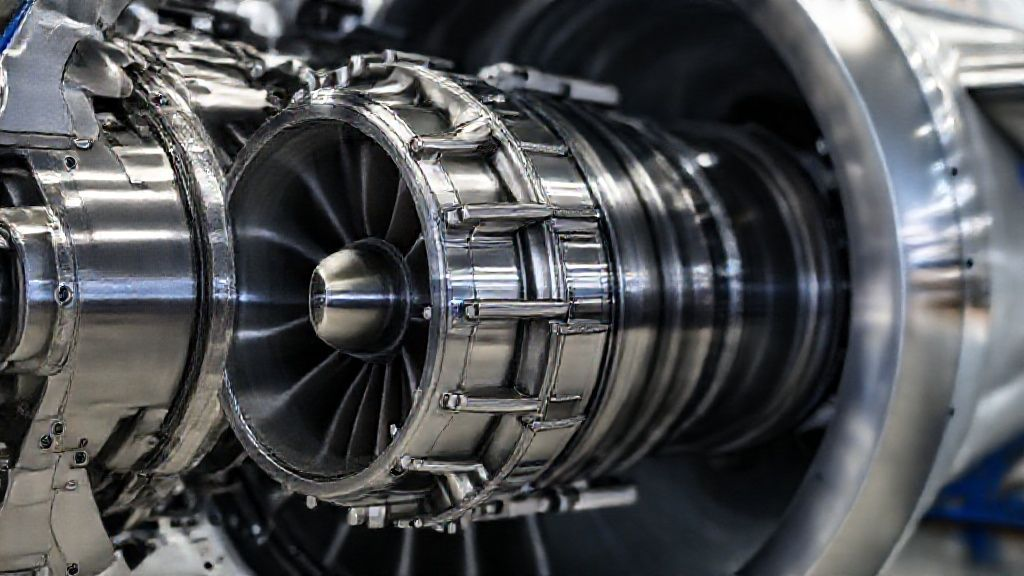

In aerospace, titanium forms essential structural components. Aircraft frames, engine parts, and landing gear utilize titanium plates. Their high strength-to-weight ratio reduces fuel consumption and increases payload capacity.

Medical implants heavily rely on titanium's biocompatibility. Bone plates, joint replacements, and dental implants are examples. Titanium integrates well with the human body, minimizing rejection.

Marine engineering benefits from titanium's corrosion resistance. Submarine components, offshore platforms, and heat exchangers use titanium. It withstands prolonged exposure to saltwater without degradation.

The chemical processing industry employs titanium in reactors and piping. Its resistance to aggressive chemicals is invaluable. This ensures safety and longevity in corrosive environments.

Overcoming Challenges: Troubleshooting Titanium Fabrication

Fabricating titanium can present several challenges. Awareness and proper techniques mitigate risks. This ensures high-quality components.

Cracking can occur during forming or welding. Preheating before forming can reduce this risk. Careful control of welding parameters prevents hot cracking.

Distortion is another common issue. It results from heat input during welding or machining. Proper fixturing and stress relief minimize distortion.

Tool wear is significant when machining titanium. Using appropriate tooling and cutting fluids is crucial. Optimized speeds and feeds extend tool life.

Contamination during welding is a major concern. Strict adherence to shielding gas protocols is essential. Maintaining a clean work environment prevents defects.

Addressing these challenges effectively leads to improved efficiency. It also ensures the overall quality of fabricated titanium components.

The Horizon of Titanium: Emerging Technologies and Sustainability

The future of titanium manufacturing is dynamic. Emerging technologies are expanding its capabilities. These innovations promise even greater versatility.

Additive manufacturing (3D printing) is revolutionizing titanium fabrication. It enables the creation of complex geometries. This reduces material waste and lead times.

New titanium alloys are also under development. These alloys offer enhanced properties. They target specific applications with improved performance characteristics.

Sustainability is a growing focus in the industry. Titanium recycling initiatives are gaining traction. They aim to reduce environmental impact and conserve resources.

Manufacturers are also exploring more energy-efficient production methods. These advancements ensure titanium's continued relevance. They solidify its role in future engineering challenges. Metal-Pages often highlights such trends.

Frequently Asked Questions About Titanium Plates

What are the primary advantages of using titanium plates?

Titanium plates offer an exceptional strength-to-weight ratio. They also feature outstanding corrosion resistance. Their biocompatibility is crucial for medical applications.

How do I choose the correct titanium grade for my project?

The choice depends on required strength, ductility, and corrosion resistance. Commercially Pure (CP) grades suit general corrosion needs. Ti-6Al-4V (Grade 5) is for high-strength applications. Consult specifications and application engineers for guidance.

What are common fabrication challenges with titanium plates?

Challenges include titanium's reactivity with air during welding. Its low thermal conductivity can cause tool wear during machining. Significant springback also occurs during forming operations.

Can titanium plates be customized to specific dimensions?

Yes, leading manufacturers like China Titanium Factory offer custom cutting and sizing. They can meet precise project specifications. This minimizes waste and optimizes material use.

What is the typical lead time for custom titanium plate orders?

Lead times vary based on grade, dimensions, and order volume. Standard grades and sizes typically have shorter lead times. Custom or specialized orders may require more time for production. It is best to consult directly with the supplier for accurate estimates.

Your Partner in Advanced Titanium Solutions

Navigating the complexities of titanium plate specifications and fabrication requires a trusted partner. At China Titanium Factory, we combine global leadership with unparalleled technical expertise. We deliver reliable, high-efficiency titanium solutions for your most demanding projects.

From aerospace to medical, our commitment to quality and precision ensures your success. Discover the difference that true expertise makes.

Connect with Our Experts Today