What is Titanium Anodizing and Why Does Cost Matter?

You're developing a product. It needs to be tough, look good, and maybe even be biocompatible. Titanium often fits the bill. But raw titanium? It's strong, sure, yet sometimes lacks that extra edge in surface performance or visual appeal. That's where titanium anodizing steps in.

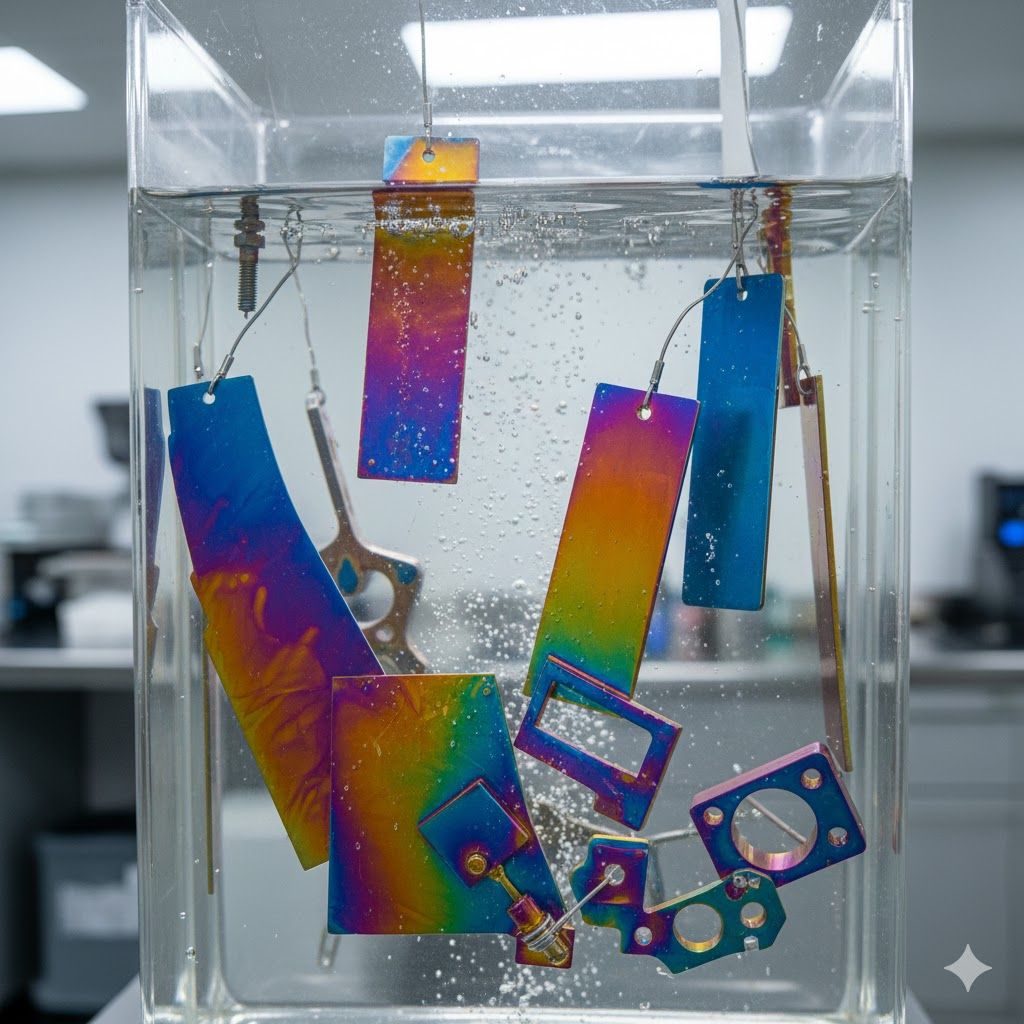

This electrochemical process creates a controlled oxide layer on the titanium surface. It enhances durability, adds corrosion resistance, and allows for stunning, vibrant colors without dyes. Think medical implants, aerospace components, or high-end consumer goods. Its benefits are clear.

However, getting those benefits isn't free. Understanding the true cost of titanium anodizing is crucial for your bottom line. It's not just a line item; it's an investment. Knowing what drives pricing helps you budget effectively, avoid surprises, and ultimately, get more bang for your buck.

Anodizing: An electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. This process enhances corrosion and wear resistance, and allows for better adhesion of paint primers and glues than bare metal. For titanium, it also enables a broad spectrum of iridescent colors.

Key Factors Influencing Titanium Anodizing Service Costs

Calculating the exact price for titanium anodizing isn't always straightforward. Many variables are at play. Think of it like a recipe: a few ingredients change, and the whole dish changes price. We'll get down to brass tacks here, breaking down what truly moves the needle on your invoice.

How Surface Area and Part Complexity Affect Pricing

Size matters. So does shape. Larger parts, naturally, require more chemical solution, more electricity, and more processing time. That pushes costs up. But it's not just sheer volume.

Complex geometries are a whole different ballgame. Intricate details, tight corners, or internal surfaces demand specialized fixturing. This ensures uniform current distribution and proper coating. Poor fixturing leads to inconsistent finishes, and nobody wants that. Custom fixturing costs time and materials, directly impacting your quote. It's often the hidden cost that catches businesses off guard.

Choosing Your Anodizing Process: Cost Implications

Not all anodizing is created equal. The type of anodizing process you choose significantly impacts the price. Generally, two main types stand out for titanium: Type II (often aesthetic) and Type III (hardcoat).

Type II anodizing, known for its vibrant colors, is typically less intensive. It focuses on appearance and light corrosion resistance. Type III, or hardcoat anodizing, is a different animal. This process creates a thicker, harder, and much more durable oxide layer. It demands more specialized equipment, longer processing times, and tighter controls. Expect hardcoat anodizing to cost more due to its superior functional properties.

Hardcoat Anodizing: A process that produces a dense, extremely hard, and abrasion-resistant oxide layer on a metal surface, typically thicker and more robust than conventional anodizing. For titanium, this significantly boosts wear resistance and protective qualities.

Volume Discounts: Maximizing Value for Your Project

Economies of scale are a big deal in metal finishing. Need a handful of prototypes? Expect a higher per-piece cost. Placing a large order for thousands of units? The price per part will drop. Significantly.

Setup costs for anodizing are fixed, whether you process ten parts or ten thousand. These include chemical bath preparation, fixturing, and quality checks. Spreading these fixed costs across more units drastically reduces the individual part price. If you’re planning a large production run, don’t hesitate to ask about volume tiers. It could save you a bundle.

The Cost of Color: Aesthetic Choices in Anodizing

Titanium is unique. It can achieve a spectrum of colors through interference with light, simply by varying the oxide layer thickness. No dyes needed. This makes it a designer's dream.

However, specific colors or multi-color finishes can affect pricing. Achieving a very precise hue requires stringent control over the electrical current. Multi-color finishes? That means masking off areas and running parts through the process multiple times, each at a different voltage. This adds labor and time, pushing up the price. Think of it as custom paint job versus a standard finish. The more bespoke, the higher the tab.

Preparation and Finishing: Hidden Cost Considerations

The anodizing bath is only one part of the equation. What happens before and after is equally critical, and it comes with costs. Pre-treatment steps, like thorough cleaning, degreasing, and sometimes polishing, are non-negotiable. Any surface contamination will lead to a poor finish. Masking certain areas to prevent anodizing also adds labor.

Post-treatment includes rinsing, sealing (especially important for corrosion resistance), and rigorous inspection. These steps ensure the quality and longevity of the anodized layer. Don't gloss over these. They're essential for a durable, high-quality finish, and they're baked into the overall service cost. Skimping here is a false economy.

For more details on proper metal finishing techniques, check out resources from ASM International, a leading authority on materials science.

Meeting Industry Standards: Impact on Anodizing Costs

Certain industries demand more. Medical devices, for example, require impeccable surface finishes and strict biocompatibility. Aerospace components need finishes that withstand extreme conditions and meet precise military specifications. These aren't just suggestions; they're mandates.

Achieving these standards involves more than just running parts through a tank. It means enhanced process controls, more frequent bath testing, specialized quality assurance protocols, and extensive documentation. All of this adds to the operational overhead. When your project requires certifications like ISO 13485 or specific MIL-specs, expect the cost to reflect that added layer of rigor and accountability. It's the price of precision and peace of mind.

The International Organization for Standardization (ISO) provides comprehensive guidelines for medical device quality management, directly influencing finishing requirements and costs.

Transparent Pricing: How to Get an Accurate Anodizing Quote

Nobody wants sticker shock. Getting a precise quote for titanium anodizing shouldn't feel like pulling teeth. Transparency is crucial. We believe in cutting through the noise, offering clear, understandable pricing. Here’s what you need to know and provide to ensure you get an accurate estimate the first time.

Our Streamlined Quoting Process: From Inquiry to Delivery

We aim for efficiency. Your time is valuable. To provide a precise quote, we typically need a few key pieces of information:

Part Geometry: CAD files (STEP, IGES, SolidWorks) are best. These allow us to accurately calculate surface area and assess complexity.

Material Grade: Specify the exact titanium alloy. Different grades can react slightly differently.

Anodizing Type: Do you need aesthetic (Type II) or hardcoat (Type III)? What color, if any?

Quantity: Provide estimated batch sizes and annual volumes. Remember those volume discounts.

Specifications: Any specific industry standards (e.g., medical, aerospace) or performance requirements?

Lead Time: What's your project timeline? Expedited services might carry a premium.

Once we have this, our experts review your project. We assess fixturing needs, process steps, and quality requirements. You'll receive a detailed quote, often within 24-48 hours, outlining all costs and projected lead times. No runaround, just clear information.

Real-World Examples: Estimating Your Anodizing Expenses

Let's look at some hypothetical scenarios to give you a clearer picture. These are illustrative, not exact quotes, but they demonstrate how factors influence pricing.

| Project Type | Key Characteristics | Expected Cost Drivers | Cost Range (Per Piece, Illustrative) |

|---|---|---|---|

| Small-Batch Jewelry | Low volume (10-50 pieces), intricate design, vibrant Type II colors. | High setup cost per piece, manual handling, precise color matching. | $5 - $25+ |

| Medium-Volume Medical Components | Moderate volume (100-1000 pieces), Type II or III, strict compliance (ISO 13485). | Process control, certification, robust quality inspection, specialized cleaning. | $2 - $15 |

| Large Industrial Parts | High volume (5000+ pieces), Type III hardcoat, less aesthetic focus. | Material volume, bath capacity, automation potential, wear resistance. | $0.50 - $5 |

As you can see, the range is wide. Every project is unique, and getting a custom quote is always the best path.

Ready for a Quote? Contact Our Experts

Got a project simmering? Don't let cost uncertainty hold you back. Our team is ready to provide a detailed, no-obligation quote tailored to your exact specifications. Send us your CAD files and requirements. We'll help you navigate the options and find the most cost-effective solution without cutting corners on quality.

Beyond the Basics: Exploring Titanium Anodizing Types & Uses

Titanium anodizing isn't a one-size-fits-all solution. It's a versatile process with applications spanning numerous industries. Understanding the specific types and their uses can further clarify why certain projects carry different price tags. It's about matching the right finish to the right need.

Aesthetic Anodizing: Vibrant Colors for Design and Branding

When visual appeal is paramount, Type II aesthetic anodizing is your go-to. This process creates a thin, transparent oxide layer that refracts light, producing a spectrum of brilliant colors. Think blues, purples, golds, and greens. The color isn't a dye; it's an optical effect. This makes it incredibly durable and fade-resistant.

Industries like jewelry, high-end consumer electronics, and decorative architectural elements leverage this for product differentiation and brand identity. Imagine a watch casing or a bespoke piece of art. The possibilities are vast, limited only by imagination and the voltage settings.

Hardcoat Anodizing: Enhancing Durability and Wear Resistance

For applications where parts take a beating, Type III hardcoat anodizing is the champion. This process creates a significantly thicker and denser oxide layer. It's tough as nails. The resulting surface boasts exceptional wear resistance, superior hardness, and robust corrosion protection. It's built to last.

You'll find hardcoat anodized titanium in demanding environments: aerospace components, military equipment, industrial machinery parts, and medical instruments. Where reliability and longevity are non-negotiable, hardcoat anodizing stands its ground. It’s an investment in extreme performance.

The National Aeronautics and Space Administration (NASA) frequently specifies robust surface treatments like hardcoat anodizing for their critical components. Explore their technical reports for insights into high-performance material applications.

Advanced Anodizing Solutions for Unique Requirements

Sometimes, standard solutions don't quite cut it. Certain niche applications demand highly specialized anodizing processes. This could involve specific thicknesses for electrical insulation, unique surface textures for improved adhesion, or custom multi-layer finishes.

These advanced solutions often involve proprietary techniques, additional research and development, and highly controlled environments. They're not a dime a dozen. Naturally, such specialized requirements will be reflected in the project cost. When your needs are truly unique, a bespoke approach is often necessary.

Where Anodized Titanium Shines: Industry Applications

The versatility of anodized titanium makes it a hero across countless sectors. From the operating room to outer space, its properties are invaluable.

Medical Devices: Implants, surgical tools, and prosthetics benefit from biocompatibility, corrosion resistance, and sterilization compatibility.

Aerospace Components: Lightweight strength, wear resistance, and high-temperature performance for critical aircraft and spacecraft parts.

Jewelry & Fashion: Vibrant, hypoallergenic finishes for rings, earrings, and other accessories.

Industrial Machinery: Durable, corrosion-resistant parts for harsh operating environments.

Consumer Electronics: Premium feel, scratch resistance, and unique aesthetics for high-end gadgets.

Automotive: Performance parts where weight and durability are key.

Each application leverages specific anodizing properties, directly influencing the process selection and, consequently, the cost. It's about optimizing performance for the intended use.

Partner with Us: The Advantages of Our Anodizing Service

Choosing the right anodizing partner is paramount. It’s not just about getting the job done; it’s about getting it done right, on time, and within budget. We stand by our commitment to quality, expertise, and customer satisfaction. When you partner with us, you're not just buying a service; you're investing in reliability and value.

Our Commitment to Expertise and Uncompromising Quality

Experience counts. Our team of skilled technicians brings years of specialized knowledge to every project. We understand the nuances of titanium alloys and the intricacies of the anodizing process. Rigorous quality control protocols are baked into our workflow, not bolted on. From initial inspection to final packaging, every step is meticulously managed. This ensures consistent, superior results that meet, or exceed, the most stringent industry standards. No cutting corners, ever.

A Seamless Experience: From Consultation to Delivery

Communication is key. We pride ourselves on clear, proactive engagement throughout your project. Our dedicated support team is here to guide you, answer questions, and provide updates. Need advice on material preparation or shipping logistics? We've got you covered. We aim to make the entire process as smooth and predictable as possible. Your satisfaction is our priority.

See Our Work: A Gallery of Anodized Titanium

Proof is in the pudding. We invite you to explore our gallery of completed projects. See firsthand the vibrant colors, the flawless finishes, and the precision we bring to every piece. Our work speaks for itself, showcasing the versatility and quality of our titanium anodizing services. Visual examples can often convey more than words. Discover what's possible for your next project.

Frequently Asked Questions About Titanium Anodizing Costs

What is the typical lead time for titanium anodizing services?

Lead times vary widely depending on project complexity, volume, and our current workload. Standard projects often take 5-10 business days from part receipt to shipment. Rush orders are sometimes possible but may incur additional costs. We'll provide a precise estimate with your quote.

Does the color choice significantly impact the anodizing cost?

For single-color aesthetic anodizing, the impact is usually minimal. Different colors are achieved by varying voltage, which is a process adjustment rather than a material cost. However, multi-color finishes or extremely tight color matching requirements can increase costs due to additional masking, processing steps, and quality verification.

What information do you need for an accurate anodizing quote?

To give you the best quote, we need your CAD files (for surface area and complexity assessment), the specific titanium alloy, the desired anodizing type (aesthetic or hardcoat) and any color preference, the quantity of parts, and any industry specifications or performance requirements. The more detail, the better.

Is hardcoat anodizing always more expensive than aesthetic anodizing?

Generally, yes. Hardcoat (Type III) anodizing involves a more intensive process to create a thicker, denser, and more durable oxide layer. This requires more specialized equipment, longer processing times, and tighter controls, which translates to a higher cost compared to aesthetic (Type II) anodizing. The added performance benefits usually justify the investment.

Are there minimum order quantities for titanium anodizing?

While there isn't always a strict minimum number of parts, there are inherent setup costs associated with any batch. This means that ordering a very small quantity will result in a higher per-piece cost. We always encourage clients to discuss their project needs, as we can often find cost-effective solutions even for smaller runs, though larger volumes will always offer better unit pricing.

Ready to Elevate Your Product with Anodized Titanium?

Don't leave your project's finish to chance. Partner with experts who deliver unmatched quality and transparent pricing. Get a custom quote tailored to your exact needs. We're here to help you achieve the perfect finish, reliably and affordably.

Get Your Free Quote Today