Understanding Titanium Anodizing: Process Fundamentals and Dimensional Impact

Engineers and product designers often grapple with a critical question: how does surface treatment affect a component's precise dimensions? When working with titanium, this concern hits home. Titanium anodizing is a powerful surface treatment, but it's not a set-it-and-forget-it process. Ignoring its dimensional impact can lead to fitment issues, assembly headaches, and outright part failure.

Understanding the ins and outs of titanium anodizing, especially its effect on dimensions, is paramount. This guide cuts through the noise, offering a deep dive into the process, the factors that drive dimensional changes, and strategies to maintain precision engineering.

What is Titanium Anodizing? An Electrochemical Overview

At its core, titanium anodizing is an electrochemical passivation process. It forms a protective, aesthetically pleasing, and often functional oxide layer on the titanium substrate. Think of it as controlled corrosion.

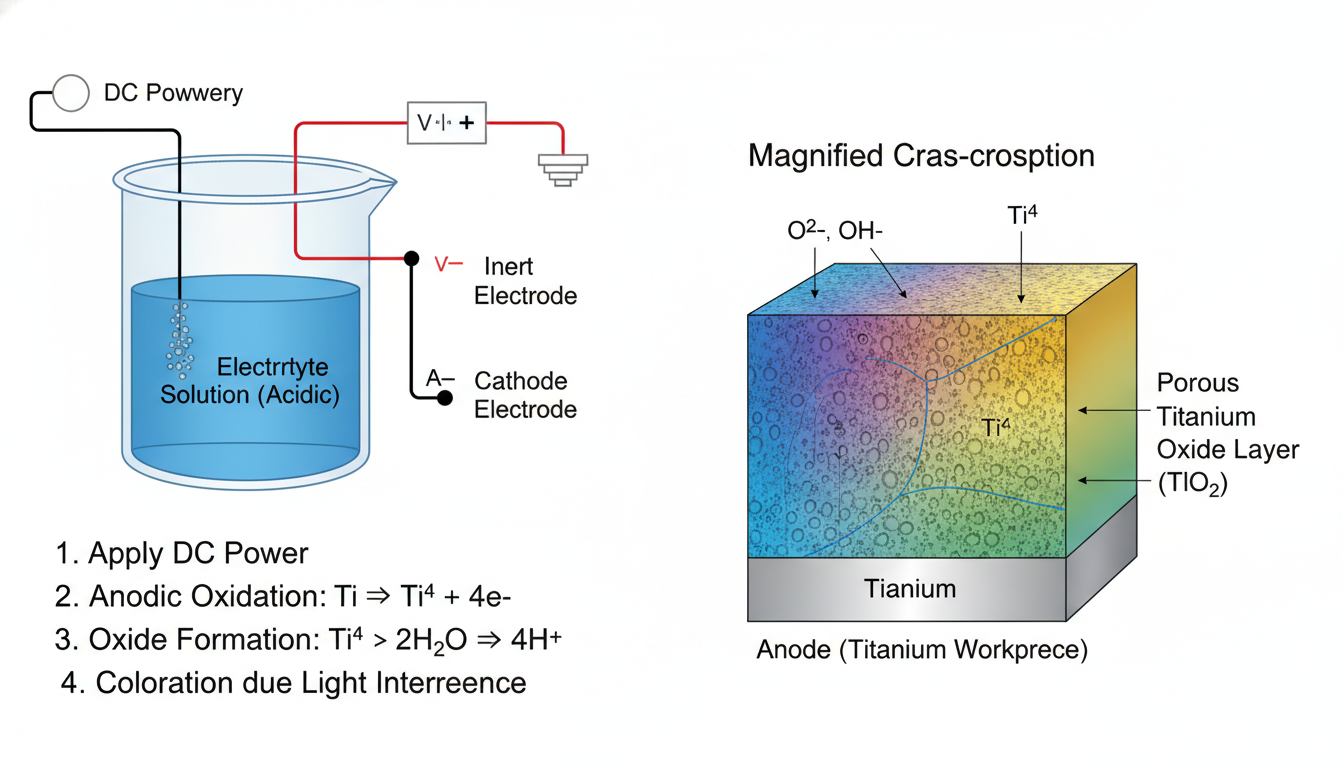

Here's how it generally works:

The titanium part acts as the anode in an electrolytic cell.

It's immersed in an electrolyte solution (often acidic).

An external DC power source applies voltage, driving an electric current.

Oxygen ions migrate to the titanium surface, reacting to form a titanium oxide (TiO₂) layer.

This oxide layer isn't just a coating; it's grown directly from the base metal. This strong metallurgical bond prevents chipping or peeling, a significant advantage over many other surface treatments.

Definition: Electrochemical Passivation

An electrochemical process where a metal is treated to become "passive," meaning it forms a protective, non-reactive surface film (like an oxide) that inhibits further corrosion or chemical reaction. In anodizing, this film is intentionally grown and controlled.

Types of Titanium Anodizing: From Decorative to Hardcoat

Not all anodizing is created equal. The type of anodizing dictates the oxide layer's characteristics, including its thickness and resulting properties.

Type II (Sulphuric Acid Anodizing): This is common for general corrosion resistance and coloring. It typically yields thinner films, often in the range of 1-5 micrometers. The colors produced are interference colors, meaning the thickness of the transparent oxide layer dictates the visible spectrum, not dyes.

Type III (Hardcoat Anodizing): A more robust process, hardcoat anodizing produces thicker, denser, and harder oxide layers, usually 25 micrometers and up. It's engineered for superior wear resistance and durability, often used in demanding applications.

Decorative Anodizing: Primarily focused on aesthetics, leveraging the interference color phenomenon to produce a spectrum of vibrant hues without added pigments. Film thickness is carefully controlled to achieve specific colors.

Each type offers distinct advantages, but understanding their typical thickness ranges is the first step in managing dimensional change.

Does Anodizing Add Thickness? Quantifying Dimensional Changes

Yes, anodizing absolutely adds thickness. This isn't a simple coating that sits on top; it's a conversion layer. The oxide grows both into the existing titanium substrate and out from the original surface.

Here’s the rub: approximately 50% of the formed oxide layer grows into the metal, and 50% grows out. This means for every unit of oxide film thickness, the overall dimension of the part increases by roughly half that value. If you form a 10-micrometer oxide layer, the part's dimension will increase by about 5 micrometers per surface.

This "50% rule of thumb" is critical. If a shaft is anodized on its circumference with a 10-micrometer film, its diameter will increase by 10 micrometers (5 µm on each side). Missing this can turn a precision fit into a no-go scenario.

Typical thickness increases:

| Anodizing Type | Total Film Thickness (µm) | Dimensional Increase (µm/surface) |

|---|---|---|

| Type II (Sulphuric) | 1 - 5 | 0.5 - 2.5 |

| Type III (Hardcoat) | 25 - 50+ | 12.5 - 25+ |

| Decorative | 0.01 - 0.5 (very thin) | 0.005 - 0.25 (negligible for many) |

Factors Influencing Dimensional Change: A Deep Dive

Controlling dimensional change boils down to meticulous process control. Several key factors are at play:

Voltage: Higher voltages generally produce thicker oxide layers. It's a direct relationship, but not always linear. Precise voltage control is non-negotiable for consistent results.

Electrolyte Composition: The type and concentration of the electrolyte solution significantly impact the growth rate and density of the oxide layer. Sulphuric acid, phosphoric acid, and others each yield different film characteristics.

Temperature: Elevated temperatures can increase the rate of oxide growth, but also potentially lead to softer, more porous films. Maintaining a stable bath temperature is crucial.

Processing Time: Longer anodizing times typically result in thicker films, up to a certain saturation point where growth slows or stops.

Titanium Alloy Type: Different titanium alloys (e.g., Ti-6Al-4V, commercially pure titanium) react differently to anodizing. Their metallurgical structure and constituent elements can influence the growth rate and final film properties. This is where experience really pays off.

These factors don't act in isolation. They form a complex interplay. A slight tweak in one parameter can ripple through the entire process, affecting the final surface finish and dimensional accuracy. Reputable anodizing facilities, like China Titanium Factory, have this down to a science, offering consistent, predictable outcomes.

For more technical details on the electrochemical process, you might consult resources like ASM International, a leading authority on materials science.

Achieving Tight Tolerances with Anodized Titanium

So, how do you hit those tight specs when anodizing adds thickness? It's all about planning ahead.

Pre-Machining Allowances: The most straightforward approach. Machine the part slightly undersized, knowing the anodizing process will bring it into tolerance. This requires precise calculation based on the expected film thickness and dimensional growth.

Masking Techniques: If only specific areas require anodizing, masking agents (tapes, lacquers, plugs) can protect critical surfaces from the electrochemical reaction. This prevents growth in unwanted areas, keeping tolerances intact where it matters most. However, masking itself adds complexity and cost.

Post-Anodizing Finishing: In some cases, light post-anodizing honing or grinding might be necessary. This is often a last resort, as it can compromise the integrity of the oxide layer or introduce new surface defects. It's a tricky path to walk.

Getting this right often involves a collaborative effort between the design engineer, machinist, and anodizing specialist. Don't leave it to chance.

Measuring and Inspecting Dimensional Changes Post-Anodizing

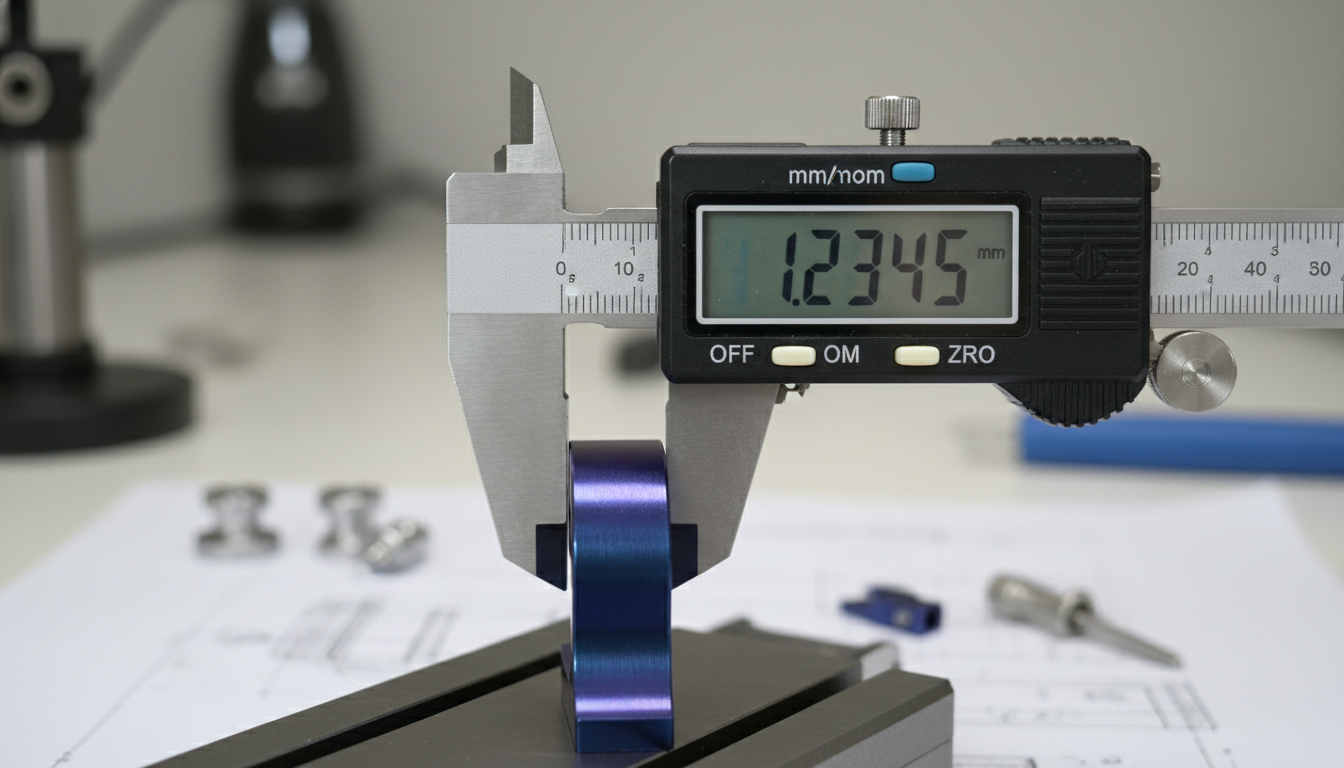

Once the parts are anodized, verification is key. You need to confirm the dimensional changes are within acceptable limits.

Eddy Current Probes: Non-destructive and highly accurate for measuring non-conductive coatings (like titanium oxide) on conductive substrates. They're quick and ideal for production environments.

Micrometers and Calipers: Standard tools for measuring overall part dimensions. Critical for validating that the dimensional increase aligns with the design allowance. Precision micrometers are a must.

Cross-Sectional Microscopy: For truly precise analysis or troubleshooting, a cross-section of the anodized layer can be prepared and viewed under a microscope. This provides a direct, visual measurement of the actual film thickness and its uniformity. This is often a destructive test, so it's typically used for process validation on sample parts.

Accurate measurement is the cornerstone of quality control. Without it, you're just guessing.

Beyond Dimensions: Enhanced Properties of Anodized Titanium

While managing dimensional change is crucial, it's important not to lose sight of the incredible benefits anodizing brings to titanium. It's not just a necessary evil; it's a value-add.

Improved Corrosion Resistance: The passive oxide layer acts as an excellent barrier against harsh environments, significantly extending the lifespan of titanium components. This is a big deal in marine, chemical, and medical applications.

Enhanced Wear Resistance: Especially with hardcoat anodizing, the increased surface hardness can reduce friction and wear, making parts more durable and reliable.

Superior Biocompatibility: For medical implants, anodizing creates an even more biocompatible surface, promoting better integration with human tissue and reducing rejection risk. This is a game-changer for devices that go inside the body.

Aesthetic Appeal: The ability to produce vibrant, consistent colors without dyes is a significant draw. These optical interference colors are stable and fade-resistant, offering unique design possibilities for consumer goods, jewelry, and architectural elements.

These enhanced properties often justify the effort required to manage dimensional changes. It's a trade-off that often pays dividends.

Case Studies: Dimensional Control in Critical Applications

Real-world applications underscore the importance of precise dimensional control:

Aerospace Fasteners: In aircraft, every micrometer counts. Anodized titanium fasteners offer high strength-to-weight ratios and corrosion resistance. However, if the anodized layer makes a fastener too large, it won't fit its mating hole, leading to assembly delays or structural integrity issues. Engineers design for precise clearances, accounting for the anodized layer.

Medical Implants: Hip stems, dental implants, and surgical instruments often feature anodized surfaces for biocompatibility and wear. A knee implant, for instance, requires exact dimensions to articulate correctly within the human body. Any deviation from the intended size post-anodizing can cause pain, malfunction, or necessitate revision surgery.

Precision Robotics: Components in robotic arms or high-speed automation require intricate fits. Anodized titanium gears or linkages provide durability and reduced friction. If the anodized layer pushes a bearing fit out of spec, the entire assembly binds up or wears prematurely.

These examples highlight that dimensional control isn't just a theoretical exercise; it's a make-or-break factor for product performance and reliability. You can dive deeper into industry standards and best practices by checking resources like SAE International for aerospace specifications.

Optimizing Your Project: Leveraging Expert Titanium Anodizing Services

Trying to tackle the nuances of titanium anodizing dimensional change in-house can be a steep hill to climb. Specialized knowledge, calibrated equipment, and strict process control are paramount. This is where partnering with an experienced provider truly shines.

For specialized applications requiring precise control over dimensional changes and superior surface finishes, consider an expert titanium anodizing service. Reputable facilities offer comprehensive solutions tailored to your project's unique specifications, ensuring both functional performance and aesthetic integrity. They've got the tools and the know-how to consistently hit those tight tolerances. Learn more about how expert services can make a difference for your next project at China Titanium Factory.

Anodizing Titanium: How It Compares to Other Surface Treatments

Titanium isn't a one-trick pony when it comes to surface treatments. It can be electropolished, passivated, or coated with various materials. Each method has its own implications for dimensional change.

Let's put anodizing in perspective:

PVD Coatings (Physical Vapor Deposition): These are thin, hard coatings applied in a vacuum. Think nitrides (TiN, CrN) or DLC (Diamond-Like Carbon). PVD layers are typically very thin, often less than a few micrometers, and add uniform thickness to the part. Dimensional impact is usually minimal, but adhesion can be an issue if the surface isn't meticulously prepared.

Electroplating: Applying a metallic layer (e.g., nickel, copper, chrome) via an electric current. Electroplating can build significant thickness, much like anodizing, but the layer is added rather than grown from the base metal. This can lead to adhesion problems or uneven deposition, making dimensional control more challenging without careful process tuning.

Passivation: A chemical process that removes free iron or other contaminants from the surface, enhancing the natural passive oxide layer. It doesn't add any measurable thickness. Its purpose is purely corrosion resistance, with no aesthetic or wear benefits.

Anodizing stands out by creating an integral, highly adherent oxide layer with tunable properties, including precise control over thickness and color, making it distinct from mere coatings or passive treatments.

Dimensional Impact: Anodizing vs. PVD and Electroplating

When it comes to dimensional impact, anodizing sits in a unique spot:

Anodizing: Grows a layer that's half into, half out of the base metal. You get dimensional growth, but it's well-bonded and predictable.

PVD: Adds material entirely on top of the surface. The dimensional increase is equal to the coating thickness. These layers are thin, so the impact is often negligible for many applications.

Electroplating: Also adds material entirely on top. However, plating can be much thicker than PVD, leading to significant dimensional changes. It's often harder to achieve uniform thickness, especially on complex geometries, making precise dimensional control a bigger headache.

For applications where an integral, hard, biocompatible, or colorful surface is needed alongside moderate dimensional changes, anodizing often wins the day. For minimal dimensional change with hard, thin films, PVD might be preferred. For heavy metallic build-up, electroplating is the go-to, but be ready for the dimensional challenges that come with it.

Troubleshooting & Best Practices for Minimizing Dimensional Variation

Minimizing dimensional variation in anodized titanium isn't black magic; it's good engineering. Here are some best practices:

Design for Anodizing: Factor in the dimensional increase from the very start of your design process. Don't add anodizing as an afterthought.

Material Consistency: Use consistent titanium alloy batches. Variations in alloy composition can affect anodizing response.

Surface Preparation: Ensure parts are immaculately clean and uniformly prepared before anodizing. Contaminants can lead to uneven oxide growth.

Rack Design: Proper racking ensures uniform current distribution and prevents "hot spots" that can cause localized thickness variations.

Process Monitoring: Continuously monitor voltage, current density, temperature, and electrolyte concentration. Deviations here are often the culprits behind inconsistent film thickness.

Batch Control: For critical applications, anodize parts in controlled batches and verify dimensions from each batch.

Communication is Key: Keep an open line with your anodizing partner. Clearly communicate your dimensional tolerances and functional requirements. A good partnership can solve a lot of headaches before they even start.

Sticking to these principles will keep your projects on track and your parts within spec.

Frequently Asked Questions About Titanium Anodizing Dimensional Change

Q1: Is titanium anodizing a coating or a conversion?

It's a conversion. Unlike a coating that's applied on top of the surface, anodizing chemically converts the surface layer of the titanium into an oxide. This means it grows both into and out of the original material, creating an integral layer with excellent adhesion.

Q2: How much dimensional increase should I expect for standard titanium anodizing?

For most standard (Type II) titanium anodizing, you can expect the overall dimension to increase by approximately 50% of the total oxide film thickness. For example, a 4-micrometer film will increase the part's dimension by about 2 micrometers per surface.

Q3: Can I anodize titanium parts to "zero" dimensional change?

No, not truly. Since the oxide layer grows both into and out of the base metal, there will always be some dimensional increase. However, for very thin decorative films (nanometer scale), the dimensional change can be practically negligible for many applications. For critical tolerances, you must account for the increase.

Q4: Does the type of titanium alloy affect dimensional change?

Yes, it can. Different titanium alloys have varying metallurgical structures and elemental compositions, which can influence how quickly and uniformly the oxide layer forms. Commercially pure titanium (CP Ti) might react differently than alloys like Ti-6Al-4V. Expert anodizers understand these nuances.

Q5: What are the biggest mistakes to avoid when targeting tight tolerances with anodized titanium?

The biggest blunders include not accounting for the dimensional increase in the initial design, failing to communicate precise tolerance requirements to the anodizer, and inconsistent surface preparation. Also, trying to achieve extremely thick hardcoat films on parts with very tight pre-anodizing tolerances without proper allowances is a recipe for trouble.

Need Precision Titanium Anodizing?

Don't let dimensional changes throw a wrench in your project. Partner with experts who understand the science and precision required for flawless titanium anodizing.

From medical devices to aerospace components, we deliver superior surface finishes with tight dimensional control. Let's make your vision a reality.

Get a Quote from China Titanium Factory Today!