What is Titanium Anodizing? An Introduction

Titanium is known for its incredible strength-to-weight ratio and corrosion resistance. But sometimes, even titanium needs a boost. That's where anodizing comes in.

Anodizing is not just a fancy word; it's a game-changer for titanium. It's an electrochemical passivation process. This means we're intentionally growing a controlled oxide layer on the metal's surface. Think of it as giving titanium a natural, super-protective skin.

Anodizing: An electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. For titanium, this process naturally forms a tenacious oxide layer, often with vibrant colors.

This isn't a coating that sits on top. It’s an integral part of the metal itself. This controlled oxidation enhances properties that are already impressive. From medical implants to high-performance aerospace components, an anodized finish often makes the difference.

Understanding this fundamental process is key to appreciating the vast potential of titanium in modern manufacturing. It’s about taking a great material and making it even better.

Why Anodize Titanium? Unlocking Key Benefits

Why go through the trouble of anodizing titanium? The reasons are compelling, touching on performance, aesthetics, and critical functionality. It's more than just skin deep.

Enhanced Corrosion Resistance

Titanium is already a corrosion champion. But anodizing takes it to another level. The denser, more uniform oxide layer created by the process provides superior resistance to harsh chemicals and environments. This is particularly vital in marine, chemical processing, and medical fields where failure isn't an option.

Improved Wear Resistance

While not as hard as some ceramic coatings, the anodized layer significantly improves the surface hardness and wear resistance of titanium. This means parts last longer, especially those subjected to friction or repeated contact. Less wear means less maintenance and greater reliability.

Aesthetic Appeal and Coloration

Here's where titanium truly shines, literally. Unlike other metals, titanium anodizing produces a spectrum of vibrant colors without any dyes. It's all about light interference, which we'll cover later. This opens up incredible design possibilities for consumer goods, jewelry, and architectural elements. It’s a custom look, baked right into the metal.

Critical Biocompatibility for Medical Applications

For medical devices and implants, biocompatibility is non-negotiable. Anodizing enhances titanium's natural biocompatibility by creating a stable, inert surface. This reduces the risk of adverse reactions in the human body, making it the material of choice for prosthetics, surgical tools, and dental implants. It's literally a life-saver.

These benefits aren't just theoretical. They translate into tangible advantages for engineers and manufacturers looking for peak performance from their materials. For high-quality custom titanium fabrication and surface treatments, understanding these benefits is paramount.

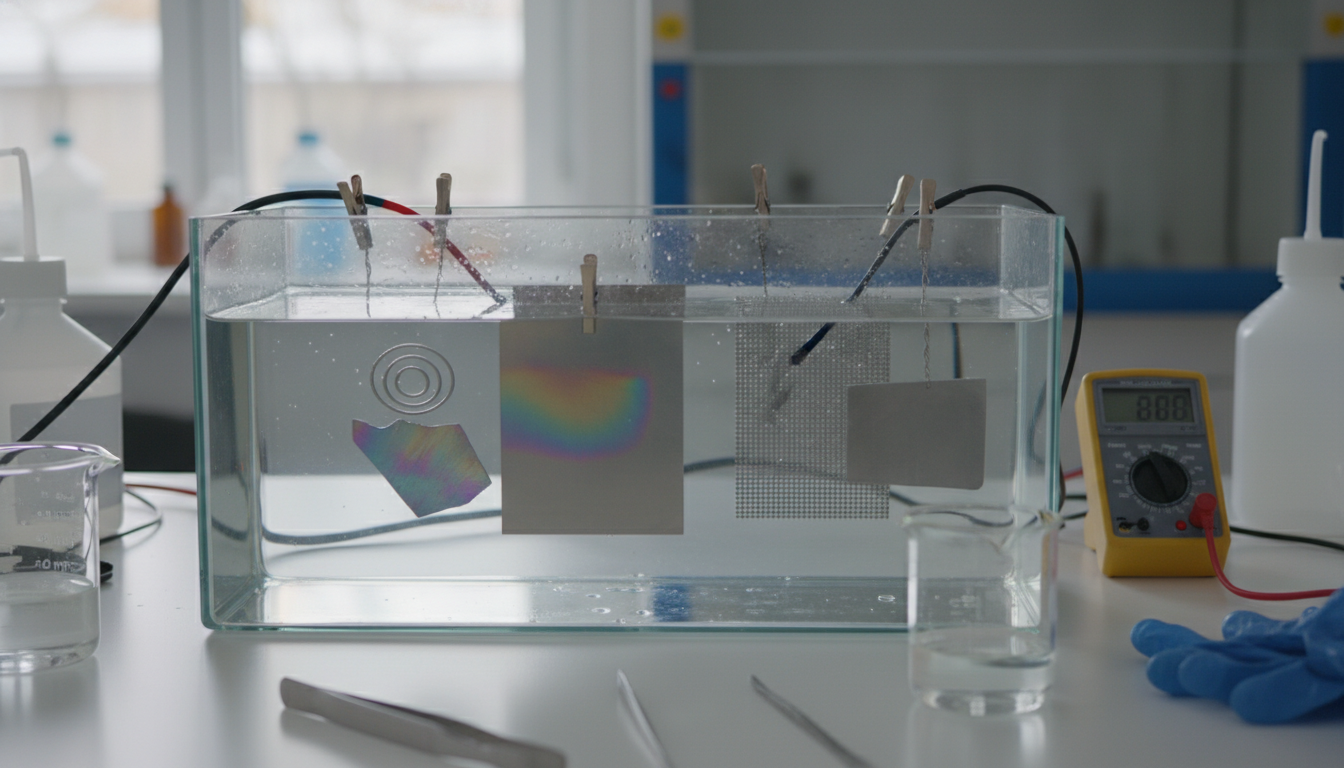

The Science Behind the Shine: How Titanium Anodizing Works

Anodizing titanium isn't magic; it's precise electrochemistry. The process involves submerging the titanium part into an electrolyte solution and passing an electric current through it. It’s a controlled oxidation process, building up a protective layer atom by atom.

Necessary Equipment

You'll need a few key pieces of gear:

DC Power Supply: Crucial for controlling voltage and current. Precision is key.

Electrolytic Bath: A tank to hold the electrolyte.

Cathode: An inert material (e.g., stainless steel) submerged in the bath.

Anode: Your titanium part, connected to the positive terminal.

Agitation System: To ensure uniform electrolyte contact.

Temperature Control: To maintain optimal bath conditions.

Types of Electrolytes Used

The choice of electrolyte is critical. Common options include:

Phosphoric Acid: Often used for Type II (color) anodizing.

Sulfuric Acid: For Type III (hard coat) anodizing, though less common for titanium's aesthetic coloring.

Non-Fluoride Electrolytes: Safer and often preferred for specific applications.

The Role of Voltage and Current Density

This is where the rubber meets the road. As voltage increases, the oxide layer thickens. This thickening directly influences the color observed (more on that later). Current density, or the amount of current per surface area, dictates the speed of the oxide growth. Too high, and you risk burning the surface. Too low, and the process crawls.

Optimal Duration

The process duration is relatively short, often just a few minutes, once the desired voltage is reached. The formation of the oxide layer is self-limiting; as the layer grows, its electrical resistance increases, naturally slowing the current until it almost stops at a given voltage. This self-limiting nature makes titanium anodizing quite controllable.

Mastering these variables is essential for consistent, high-quality results. It’s a delicate balance, but one that yields impressive dividends in material performance and appearance.

Choosing Your Alloy: Best Titanium Grades for Anodizing

Not all titanium alloys are created equal when it comes to anodizing. While most titanium grades can be anodized, some perform better or offer specific advantages. Knowing which titanium alloys to pick can save headaches down the line.

Commercially Pure (CP) Titanium (Grades 1-4)

These grades are generally excellent candidates for anodizing. Their high purity allows for a very uniform and consistent oxide layer. CP titanium is often chosen for applications where ductility and corrosion resistance are primary, such as heat exchangers and chemical processing equipment. Grade 2 titanium, in particular, is frequently anodized for its reliable color development.

Grade 5 (Ti-6Al-4V): The Workhorse

When someone says "titanium," they're often talking about Grade 5. Ti-6Al-4V is an alpha-beta alloy, celebrated for its exceptional strength-to-weight ratio and good corrosion resistance. It’s a staple in aerospace, medical, and automotive industries. Anodizing Grade 5 titanium is very common, providing that extra layer of protection and aesthetic appeal.

The anodizing process on Ti-6Al-4V is similar to CP grades, but the presence of aluminum and vanadium can subtly influence the oxide growth. Experienced processors understand these nuances, ensuring a consistent finish even on this complex alloy. For demanding applications requiring both strength and enhanced surface properties, Ti-6Al-4V anodizing is often the answer.

Other Alloys and Considerations

Other titanium alloys, like Grade 23 (Ti-6Al-4V ELI – Extra Low Interstitials), also anodize well, especially for medical implants where purity is paramount. Some beta alloys can also be anodized, though their response might differ slightly due to their unique microstructures. Always consult with a specialist if you're working with less common alloys to ensure optimal results.

The key takeaway? While most titanium is amenable to anodizing, understanding the specific alloy's characteristics helps tailor the process for the best possible outcome. China Titanium Factory works with a wide range of titanium grades, ensuring the right material for your project.

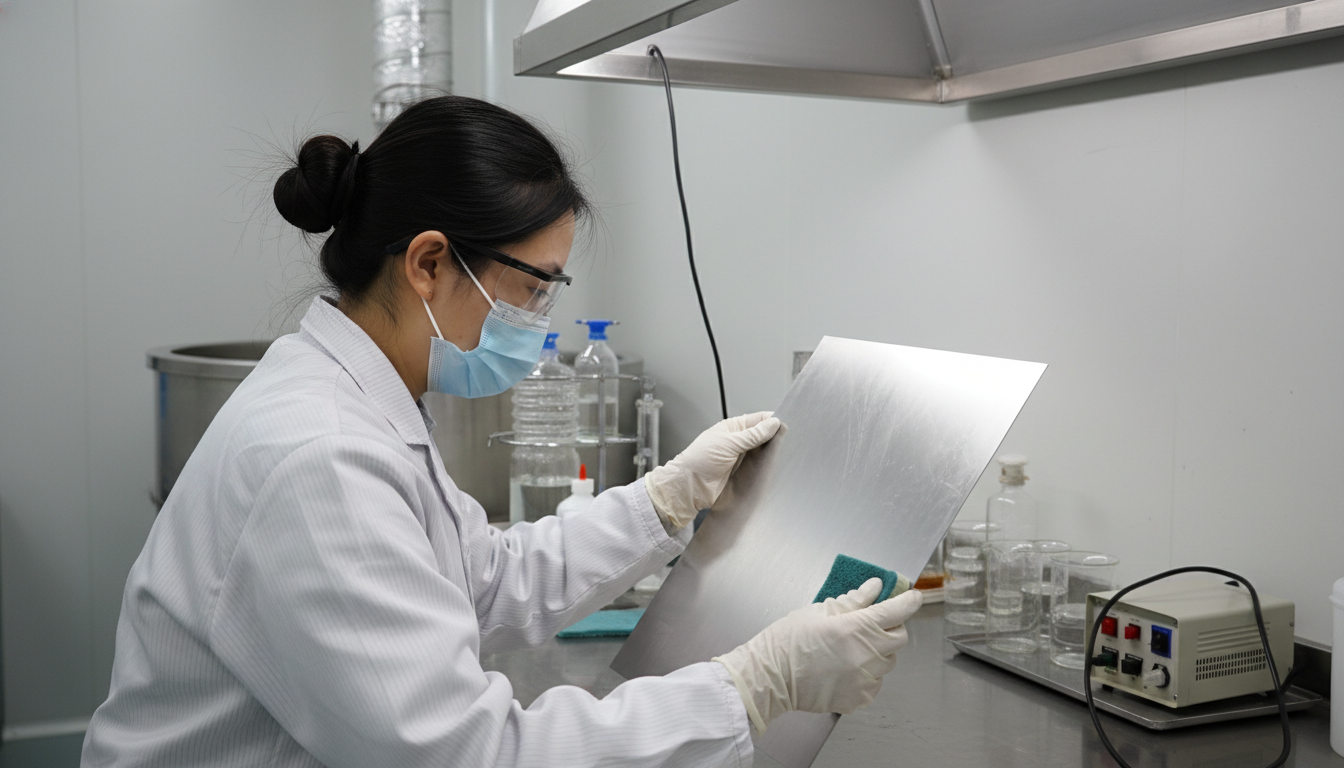

Flawless Foundation: Essential Surface Preparation for Titanium Anodizing

You wouldn't paint a dirty wall, right? The same logic applies to anodizing. Surface preparation isn't just important; it's absolutely critical. A clean, uniform surface is the bedrock of a successful anodized finish. Skimp here, and you're asking for trouble.

Cleaning and Degreasing

Before any electrochemical treatment, parts must be spotless. This means removing all oils, greases, fingerprints, and machining residues. Common methods include:

Alkaline Cleaning: Immersion in hot alkaline solutions to saponify oils and emulsify greases.

Ultrasonic Cleaning: Using high-frequency sound waves in a cleaning solution to dislodge stubborn contaminants.

Solvent Degreasing: For heavy oils, though less environmentally friendly than aqueous solutions.

Etching Techniques

Etching creates a uniform surface topography, improving adhesion and ensuring a consistent oxide layer. It removes any surface impurities and provides a fresh, reactive surface.

Acid Etching: Solutions containing hydrofluoric acid (HF) and nitric acid (HNO3) are common. HF dissolves titanium, while HNO3 passivates it, creating a controlled etch. This step requires extreme caution due to the hazardous nature of HF.

Alkaline Etching: Some milder alkaline etches can be used for specific surface finishes.

Post-Preparation Handling

After cleaning and etching, parts should be handled with clean gloves to avoid reintroducing oils. They should be immediately transferred to the anodizing bath. Any delay can lead to re-oxidation or contamination, impacting the final anodized quality. Getting this stage right is half the battle won for any professional titanium anodizing service.

A Spectrum of Possibilities: Achieving Colors with Titanium Anodizing

The vibrant colors of anodized titanium are truly captivating. What's even more fascinating? They're not from dyes or pigments. This isn't paint. It's pure physics at play, a dazzling optical illusion created by light itself.

The Science of Light Interference

When light hits the anodized titanium surface, it encounters two reflective surfaces: the top of the transparent oxide layer and the underlying titanium metal. As light reflects off both surfaces, the waves interfere with each other. Depending on the thickness of the oxide layer, certain wavelengths of light are amplified, while others are canceled out. The result? We perceive a specific color.

Light Interference: A phenomenon where two light waves superpose to form a resultant wave of greater, lower, or the same amplitude. In titanium anodizing, this is responsible for the perceived color based on the oxide layer's thickness.

It's akin to the colors you see in a soap bubble or an oil slick on water. The thickness of the film dictates the color.

Voltage and Titanium Color Correlation

This is the magic wand. By precisely controlling the voltage during the anodizing process, we can control the thickness of the oxide layer. Higher voltages produce thicker layers, which in turn shift the perceived color. A few volts can make a world of difference.

Here’s a rough guide to the voltage-color relationship, though variations exist based on electrolyte, alloy, and surface finish:

| Voltage Range (V) | Perceived Color |

|---|---|

| 10-15 | Tan/Brown |

| 20-25 | Bronze/Purple |

| 30-35 | Dark Blue |

| 40-45 | Light Blue/Teal |

| 50-55 | Yellow/Gold |

| 60-65 | Pink/Rose Gold |

| 70-80 | Green |

| 90+ | Violet/Magenta |

This precise control allows for incredible customization. It's a powerful tool for branding and aesthetic differentiation, making titanium parts truly stand out.

Troubleshooting Common Issues in Titanium Anodizing

Even with the best intentions and equipment, issues can crop up. Anodizing isn't always a walk in the park. Knowing how to identify and fix common problems saves time, material, and sanity. Let’s tackle some typical headaches.

Uneven Coloration or Patchiness

This is a frequent complaint. If your titanium part looks like a tie-dye project gone wrong, here's what to check:

Inadequate Surface Preparation: The most common culprit. Any residual oil, grease, or uneven etching will cause inconsistent oxide growth. Go back to basics: clean, degrease, and etch thoroughly.

Poor Electrical Contact: Ensure your anode connection is solid and evenly distributed. Loose clips or poor racking can lead to areas with insufficient current.

Stagnant Electrolyte: Lack of agitation can cause localized depletion of ions, leading to uneven growth. Stir things up!

Temperature Fluctuations: Inconsistent bath temperature affects the reaction rate. Maintain a stable temperature.

Lack of Color or Dull Finish

If your titanium isn't popping with color:

Insufficient Voltage: The oxide layer isn't thick enough to produce the desired interference color. Slowly increase the voltage until the target color is achieved.

Contaminated Electrolyte: Impurities can hinder oxide formation. Regularly filter and maintain your bath.

Over-etching: A heavily etched surface can sometimes yield a duller color, as the microscopic roughness scatters light differently.

Pitting or Surface Damage

This is more serious. Pitting indicates localized corrosion during the process:

Fluoride Contamination: Even trace amounts of fluoride ions in the electrolyte can cause pitting, especially at higher voltages. Ensure your water source and chemicals are fluoride-free for certain types of anodizing.

Overheating: Localized overheating due to excessive current density can lead to defects.

Poor Rinsing: Acid residues from etching can cause localized attack if not thoroughly rinsed off.

Troubleshooting is part of the learning curve. Document your process, note deviations, and adjust methodically. A systematic approach is your best friend here. For complex issues, sometimes it's best to consult with experienced titanium manufacturing experts.

Beyond Aesthetics: Impact on Mechanical Properties and Alternative Treatments

While the colors are eye-catching, the benefits of anodizing titanium extend far beyond good looks. It fundamentally alters the surface, influencing mechanical properties and often outperforming alternative treatments for specific applications.

Effect on Mechanical Properties

The anodized layer is typically very thin, often less than a micron. Because of this, it generally has a minimal impact on the bulk mechanical properties like tensile strength or fatigue life. However, it significantly alters surface properties:

Hardness: The ceramic-like oxide layer is harder than the underlying titanium. This boosts surface hardness, improving scratch and wear resistance.

Fatigue: While some surface treatments can introduce residual stresses that affect fatigue, well-controlled anodizing typically has a neutral or even slightly beneficial effect, as it can reduce stress concentrations on the surface. For a deeper dive into how surface treatments impact fatigue, you might refer to materials science journals or publications from organizations like ASM International.

Friction: The oxide layer can alter the coefficient of friction, which is important for moving parts.

It's crucial to remember that the properties of the oxide layer itself are distinct from the bulk material. The synergy between the two is what makes anodized titanium so effective.

Anodizing vs. Other Titanium Surface Treatments

Titanium can undergo various surface modifications, each with its own advantages. How does anodizing stack up?

Anodizing vs. PVD (Physical Vapor Deposition) Coating: PVD coatings (like TiN, TiAlN) are typically much harder and thicker, offering superior wear resistance. However, they are a deposited layer, not integral to the base metal, and can sometimes delaminate. Anodizing offers better corrosion resistance for certain environments and its inherent biocompatibility is often preferred for medical applications.

Anodizing vs. Nitriding: Nitriding (gas or plasma) diffuses nitrogen into the titanium surface, creating a very hard, wear-resistant layer. It significantly improves fatigue life but doesn't offer the aesthetic coloration of anodizing. Nitriding is typically chosen for extreme wear applications.

Anodizing vs. Polishing: Polishing is a mechanical finish improving surface smoothness and reflectivity. While it can be a pre-treatment for anodizing, it doesn't add the protective oxide layer or vibrant colors on its own.

Each treatment has its niche. Anodizing often wins for its combination of enhanced corrosion resistance, biocompatibility, and unique aesthetic possibilities, all while maintaining the integrity of the base metal. For a comprehensive look at titanium surface engineering, sources like academic research papers often provide detailed comparisons. For instance, research on titanium surface modifications for biomedical applications often compares these methods, such as those found on Google Scholar.

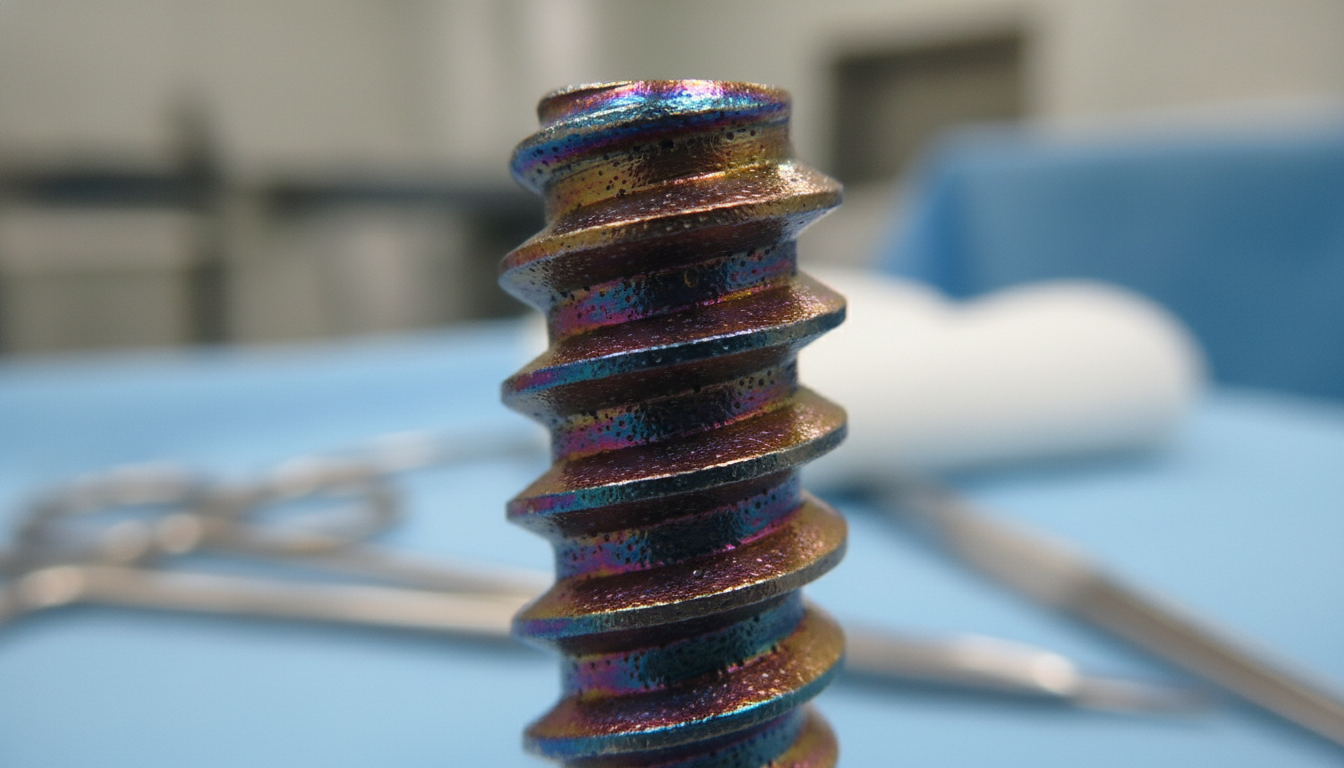

Real-World Applications of Anodized Titanium Alloys

The versatility of anodized titanium makes it a go-to material across an astonishing range of industries. From the depths of the ocean to the human body, its unique properties are put to the test every day. This isn't just theory; it's proven performance.

Aerospace and Defense

In aerospace, weight is everything. Titanium's high strength-to-weight ratio is a perfect fit. Anodizing further enhances corrosion resistance, crucial for components exposed to harsh atmospheric conditions or fuel environments. Think landing gear components, fasteners, and structural parts where reliability is non-negotiable. The added durability from anodizing keeps aircraft flying safely for longer.

Medical and Dental Devices

This is where anodized titanium truly shines. Its unrivaled biocompatibility, coupled with enhanced corrosion resistance, makes it ideal for implants. Bone screws, dental implants, surgical instruments, and even pacemakers often feature an anodized titanium surface. The ability to color-code instruments through anodizing also improves surgical efficiency and safety.

Consumer Goods and Jewelry

Here, aesthetics often take center stage. The ability to create a rainbow of colors without dyes makes anodized titanium popular for high-end jewelry, watches, eyeglass frames, and even custom knife handles. Its durability ensures these items remain beautiful for years. The unique sheen and scratch resistance add to its appeal for discerning consumers.

Automotive and Motorsports

Lightweight performance parts in racing and high-performance vehicles often use titanium. Anodizing provides corrosion protection against road salts and fluids, while also offering distinctive colored finishes for engine components, exhaust systems, and structural elements. It's about looking good and performing under pressure.

The impact of a professional titanium anodizing service on product quality and innovation cannot be overstated. From enhancing safety to boosting aesthetic appeal, anodizing unlocks titanium's full potential across the board.

Cost, Environmental Impact, and Sustainability in Titanium Anodizing

Considering a titanium anodizing service means looking beyond the immediate process. Factors like cost, environmental footprint, and long-term sustainability are significant. It’s about making smart, responsible choices.

Factors Influencing Anodizing Cost

The price tag for anodizing isn't fixed. Several variables play a role:

Part Size and Complexity: Larger or intricately shaped parts require more handling, specialized racking, and potentially longer processing times.

Volume: Like most manufacturing processes, economies of scale apply. Higher volumes generally lead to lower per-unit costs.

Desired Finish/Color: Achieving very specific or multiple colors on a single part can increase complexity and cost.

Surface Preparation: If parts arrive heavily contaminated or require extensive pre-treatment, labor costs will rise.

Labor and Overhead: The expertise required, facility costs, and energy consumption all factor in.

Environmental Impact and Sustainable Practices

Anodizing involves chemicals, so environmental considerations are real. However, the industry is increasingly focused on sustainability:

Waste Management: Proper disposal and treatment of electrolyte solutions and rinse waters are paramount. Many facilities employ advanced wastewater treatment systems to neutralize and remove hazardous components.

Chemical Selection: Moving towards less toxic electrolytes and cleaning agents reduces environmental risk. Non-fluoride baths, for example, are gaining traction.

Resource Efficiency: Optimizing energy consumption for heating and cooling baths, and using efficient power supplies, minimizes the carbon footprint.

Longevity of Products: By extending the lifespan of titanium parts, anodizing inherently contributes to sustainability by reducing the need for replacement and raw material extraction.

The Horizon: Emerging Trends and Future of Titanium Anodizing

The field of titanium anodizing isn't static. Research and development continue to push boundaries, promising even more advanced properties and novel applications. The future looks bright, colorful, and highly functional.

Innovative Techniques and Enhanced Functionality

Scientists are exploring new ways to modify the anodized layer:

Porous Anodizing: Creating highly porous oxide layers on titanium can significantly increase surface area, which is beneficial for drug delivery systems, catalytic converters, and supercapacitors.

Nanostructured Surfaces: Tailoring the nanoscale architecture of the oxide layer can lead to superhydrophobic (water-repelling) or superhydrophilic (water-attracting) surfaces, opening doors for self-cleaning materials or advanced medical diagnostics.

Multifunctional Coatings: Combining anodizing with other surface treatments to achieve synergistic properties, such as enhanced wear resistance with antimicrobial capabilities.

Gradient Anodizing: Developing methods to create a gradual change in oxide thickness across a single part, leading to gradient colors or functional zones.

Broader Applications and Industry Adoption

As these techniques mature, we'll likely see anodized titanium in even more places:

Energy Storage: Improved porous structures for battery electrodes or hydrogen storage.

Smart Materials: Surfaces that react to stimuli, potentially changing color or properties.

Consumer Electronics: Lighter, more durable, and aesthetically appealing casings for devices.

Frequently Asked Questions About Anodizing Titanium

What is the difference between Type II and Type III anodizing for titanium?

Unlike aluminum, titanium anodizing isn't strictly categorized into Type II (sulfuric) or Type III (hardcoat) by ASTM standards in the same way. For titanium, anodizing often refers to Type II (for coloring and moderate protection) or a specialized process for specific medical or aerospace requirements (often referred to as Type II or Type III for aluminum). The key distinction for titanium is typically between coloring (thin oxide) and creating thicker, harder oxide layers for wear resistance (often still achieved by increasing voltage in the same bath). The focus for titanium is often on the thickness and uniformity of the oxide for desired optical or functional properties.

How long does titanium anodizing last?

Anodized titanium is exceptionally durable. Since the oxide layer is an integral part of the metal, it won't chip, peel, or fade like painted coatings. Its lifespan depends heavily on the application and exposure to wear or harsh chemicals. In non-abrasive environments, the anodized finish can last indefinitely. In high-wear applications, the surface may eventually abrade, but the underlying corrosion resistance remains strong.

Can all titanium alloys be anodized?

Generally, yes. Most commercially pure titanium grades (Grades 1-4) and common alloys like Grade 5 (Ti-6Al-4V) are excellent candidates. The specific composition of an alloy can slightly influence the resulting color or layer thickness at a given voltage, but the process is broadly applicable. Some highly specialized alloys might require specific electrolyte formulations or process parameters.

Is anodizing titanium toxic or environmentally harmful?

The anodizing process itself involves acids and can generate hazardous waste. However, reputable facilities employ strict environmental controls, including wastewater treatment, ventilation, and safe chemical handling. The resulting anodized titanium part is non-toxic, biocompatible, and safe for human contact. The industry is continuously moving towards more environmentally friendly processes and less hazardous chemicals.

Does anodizing change the dimensions of the titanium part?

Yes, but negligibly for most applications. The oxide layer formed during anodizing is extremely thin, typically ranging from tens to a few hundred nanometers (nm), or fractions of a micron. While it adds a microscopic amount of thickness, this is usually well within manufacturing tolerances and does not affect the fit or function of precision components.