Decoding AMS Standards: Essential for Aerospace Excellence

In aerospace, precision is paramount. Every component, every material, and every manufacturing process must meet an exacting standard. There’s simply no wiggle room. This is where Aerospace Material Specifications, or AMS Standards, enter the picture. They are the bedrock of quality control and operational safety.

These specifications are more than mere guidelines. They are non-negotiable mandates. For engineers and manufacturers, understanding which industry standards, such as AMS 2487 or AMS 2488, apply to their specific materials and processes is crucial. Failure to comply can be catastrophic. It’s not just about meeting a checklist; it’s about preventing failures in environments where lives depend on flawless execution.

What are AMS Standards and Why Do They Matter?

AMS Standards are detailed material and process specifications. They dictate the chemical composition, mechanical properties, testing methods, and performance requirements for materials used in aerospace, defense, and related high-performance industries. Think of them as blueprints for material integrity.

Why do they matter? Aerospace components operate under extreme conditions: immense stress, temperature fluctuations, and corrosive environments. Without standardized materials and processes, predicting performance would be a shot in the dark. AMS standards ensure consistency and reliability across the supply chain, from raw material suppliers to finished component manufacturers.

Non-compliance isn't just a regulatory headache. It poses significant safety risks, potential for catastrophic failures, and severe financial repercussions. These standards are a critical safety net.

Aerospace Material Specification (AMS): A specific standard published by SAE International that defines the properties, processing, and testing requirements for materials, parts, and processes used in aerospace applications, ensuring consistent quality, performance, and safety.

The Guiding Hand: SAE International's Role in AMS

The development and maintenance of AMS Standards is primarily overseen by SAE International. This global association of engineers and technical experts drives the creation of standards across various industries, with a significant focus on aerospace. SAE committees, comprised of industry leaders, manufacturers, suppliers, and regulatory bodies, collaboratively draft and revise these specifications.

Their rigorous process involves extensive research, testing, and consensus building. This collaborative approach ensures that AMS standards reflect the latest technological advancements and best practices. The result? Specifications that are technically robust, globally recognized, and trusted throughout the aerospace supply chain.

Navigating the Landscape: General Categories of AMS Specifications

AMS specifications are organized logically, encompassing a broad spectrum of materials and processes. This categorization helps users quickly locate relevant standards. Understanding this structure is key to efficient material selection and process validation.

Common categories include:

| Category | Description | Examples |

|---|---|---|

| Metallic Materials | Specifications for various metals and alloys, including their composition, mechanical properties, and heat treatment requirements. | Steels, Aluminum Alloys, Titanium Alloys |

| Non-Metallic Materials | Standards for plastics, composites, elastomers, and other non-metallic substances. | Sealants, Adhesives, Composite Resins |

| Processes | Specifications for manufacturing, finishing, and treatment processes. | Plating (AMS 2487), Anodizing (AMS 2488), Welding, Heat Treatment |

| Testing Methods | Procedures for evaluating material properties and process effectiveness. | Corrosion testing, Hardness testing, NDT methods |

Each category plays a vital role in ensuring the integrity of aerospace components. The specific standards you need depend entirely on the material, its intended function, and the operating environment.

Deep Dive: Understanding AMS 2487 - Electroless Nickel Plating

AMS 2487 is a critical standard for electroless nickel (EN) plating. This specification outlines the requirements for applying autocatalytic nickel-phosphorus coatings to various metallic substrates. Electroless nickel plating provides a uniform, hard, and corrosion-resistant surface, making it invaluable in aerospace applications where consistent performance and durability are essential.

Unlike electroplating, EN plating doesn't require an external electrical current. This results in a highly uniform deposit, even on complex geometries. Such uniformity is a game-changer for intricate aerospace parts.

Applications and Key Requirements of AMS 2487

AMS 2487 finds extensive use in aerospace components subjected to wear, friction, and harsh environmental conditions. Think landing gear components, hydraulic cylinders, valve bodies, and various fasteners. It's often chosen for its ability to enhance the lifespan of parts that would otherwise degrade quickly.

Key requirements under AMS 2487 typically include:

Coating Thickness: Specified to ensure adequate protection and performance.

Hardness: Usually measured post-heat treatment, crucial for wear resistance.

Adhesion: The bond between the plating and the substrate must be robust, verified through bend tests or thermal cycling.

Corrosion Resistance: Tested via salt spray or other environmental exposure methods.

Phosphorus Content: Often specified as low, medium, or high, influencing the coating's properties.

Appearance: Uniformity, absence of blisters, pits, or other defects.

Meeting these criteria demands meticulous process control, from surface preparation to plating bath chemistry and post-treatment. Any deviation can compromise the coating's integrity.

AMS 2487 vs. Other Plating Standards: A Comparative Analysis

While other standards like ASTM B733 also cover electroless nickel plating, AMS 2487 often imposes stricter requirements and narrower tolerances specifically tailored for aerospace applications. Aerospace demands inherently higher reliability.

For instance, AMS 2487 might specify tighter controls on bath composition, more frequent testing, or higher minimum performance criteria for hardness or corrosion resistance. This increased rigor reflects the critical nature of aerospace components, where failure is not an option. When specifying materials for an aircraft or spacecraft, an engineer knows AMS 2487 provides an extra layer of assurance.

Deep Dive: Exploring AMS 2488 - Anodic Treatment of Aluminum Alloys

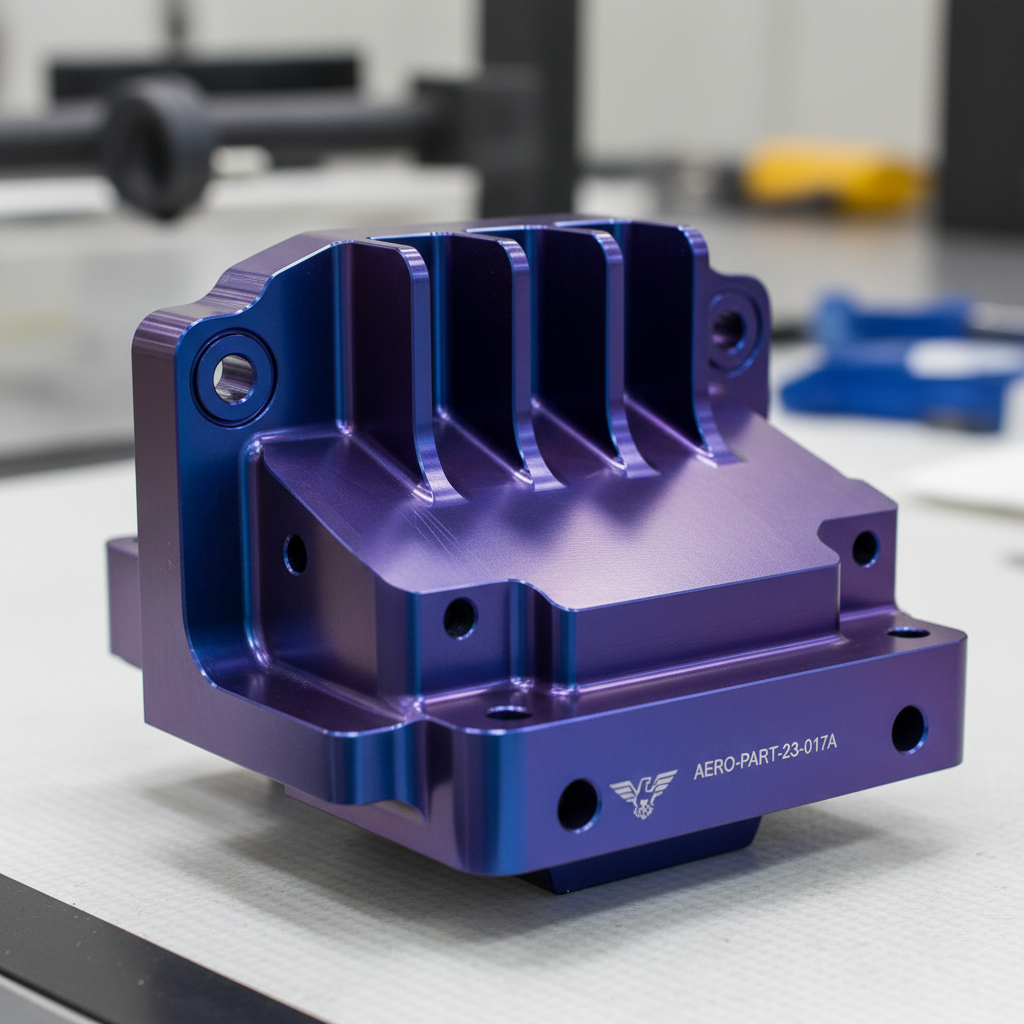

AMS 2488 specifies the requirements for the anodic treatment, or anodizing, of aluminum alloys. Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, and often decorative oxide layer. For aluminum, this process is akin to giving it a protective suit of armor.

Aluminum's light weight and strength make it ubiquitous in aerospace. However, its natural oxide layer offers limited protection. Anodizing significantly enhances its surface properties, extending the lifespan of components in demanding environments.

Applications and Types of Anodic Coatings under AMS 2488

AMS 2488 is widely applied to structural components, fasteners, housings, and decorative trim in aircraft. Any aluminum part exposed to the elements or requiring enhanced durability is a candidate for anodizing under this standard.

The standard typically covers various types of anodic coatings, each with distinct properties:

Type I (Chromic Acid Anodize): Thin, ductile, and provides excellent corrosion resistance, often used as a base for paint.

Type II (Sulfuric Acid Anodize): Thicker, harder, and can be dyed various colors. Offers good corrosion and abrasion resistance.

Type III (Hardcoat Anodize): The thickest and hardest coating, offering superior wear and abrasion resistance, alongside excellent dielectric properties. This is often referred to as "hard anodizing."

The choice of type depends on the specific application's performance requirements. For instance, a part requiring extreme wear resistance might call for Type III.

Key Requirements and Performance Characteristics of AMS 2488

Compliance with AMS 2488 involves adherence to several critical parameters:

Coating Thickness: Varies by type and application, measured precisely.

Coating Weight: Indicates the amount of oxide formed.

Density: Crucial for hardness and wear resistance.

Sealing Quality: The sealing process, often in hot water, closes pores and enhances corrosion resistance. Poor sealing undermines the coating.

Corrosion Resistance: Evaluated through salt spray tests (e.g., ASTM B117) to ensure long-term protection.

Abrasion Resistance: Particularly for Type III coatings, tested to confirm enhanced durability.

Achieving these specifications requires precise control over electrolyte composition, temperature, current density, and immersion times. Quality control checks at every stage are essential. Companies like China Titanium Factory adhere to such stringent process controls for their aerospace-grade materials and finishes.

Navigating Compliance: Selecting and Implementing AMS Standards

For aerospace manufacturers, selecting and implementing the correct AMS standards is a mission-critical task. It's not a matter of choice; it's a fundamental obligation. The process demands a thorough understanding of material science, engineering principles, and regulatory frameworks. Get it wrong, and you risk product failure and severe consequences.

Criteria for Choosing the Correct AMS Standard

Selecting the appropriate AMS standard involves a systematic approach:

Material Type: What is the base material? (e.g., aluminum alloy, titanium, stainless steel).

Component Function: What role does the part play? Is it structural, hydraulic, electrical?

Operating Environment: Will it be exposed to extreme temperatures, corrosion, vibration, or radiation?

Required Properties: What specific performance characteristics are paramount? (e.g., tensile strength, fatigue life, wear resistance, surface finish).

Process Involved: Is it a raw material, a casting, a forging, or a surface treatment?

Customer & Regulatory Requirements: What do the contract, prime contractor, or airworthiness authorities mandate?

A meticulous review of these factors will narrow down the relevant AMS specifications. Skipping this step is a common pitfall. Often, multiple standards might apply, requiring careful cross-referencing to ensure full compliance.

The Path to AMS Compliance and Certification Processes

Achieving and maintaining AMS compliance is an ongoing journey, not a one-time event. It involves robust internal quality control systems, stringent supplier qualification, and often, independent third-party audits.

Key steps typically include:

Internal Quality Management System (QMS): Implementing a QMS compliant with aerospace standards like AS9100. This provides the framework for all processes.

Supplier Qualification: Vetting raw material and process suppliers (like those providing specialized plating or anodizing services) to ensure their own compliance with relevant AMS standards. This often involves audits and regular performance reviews. China Titanium Factory exemplifies this commitment to a rigorous supply chain.

Process Control: Documenting and strictly adhering to manufacturing and treatment procedures. Every step must be repeatable and measurable.

Testing and Inspection: Performing in-process and final inspections, including destructive and non-destructive testing, to verify material and coating properties.

Documentation and Traceability: Maintaining comprehensive records for every batch and part, ensuring full traceability from raw material to finished product.

Third-Party Certification: Many prime contractors require suppliers to hold certifications (e.g., Nadcap for special processes) that validate their ability to meet AMS and other aerospace specifications.

This rigorous framework ensures that every part flying meets the highest possible standards. It’s a testament to the aerospace industry’s unwavering commitment to safety.

Essential Resources for AMS Standards and Specifications

Accessing the most current AMS standards is fundamental for compliance. The primary source is SAE International's official website, where individual standards can be purchased. Many aerospace organizations also subscribe to comprehensive databases that provide access to entire libraries of standards.

Additionally, industry associations, technical consultants, and material testing laboratories can provide invaluable support in interpreting complex specifications and ensuring proper implementation. Leveraging these resources can save time and prevent costly errors.

The Unwavering Impact of AMS Standards on Product Quality and Safety

The impact of AMS Standards on aerospace product quality and safety cannot be overstated. They are the guardians of integrity. By providing a common, rigorous language for materials and processes, they eliminate ambiguity and mandate excellence.

Every flight, every space mission, relies on components that meet these exacting specifications. From the titanium fasteners holding a wing together to the anodized aluminum skin protecting against corrosion, AMS standards ensure these parts perform as expected, every single time. Their adherence is the bedrock of public trust in air travel and space exploration. There are no shortcuts.

Frequently Asked Questions (FAQs) About AMS Standards

Understanding AMS standards can be complex. Here are answers to some common questions professionals often ask.

What does AMS stand for?

AMS stands for Aerospace Material Specification. These specifications detail the requirements for materials, parts, and processes used in aerospace and related high-performance industries.

Who develops and maintains AMS standards?

AMS standards are developed and maintained by SAE International. This process involves collaborative committees comprising experts from aerospace manufacturers, suppliers, government agencies, and academia.

Are AMS standards mandatory for aerospace manufacturers?

Yes, AMS standards are mandatory when referenced in contracts, customer specifications, regulatory requirements, or engineering drawings for aerospace components. They are critical for ensuring safety and performance.

How do I obtain copies of specific AMS standards?

Official copies of AMS standards can be purchased directly from the SAE International website or through authorized distributors of technical standards. Many aerospace companies also subscribe to digital libraries that provide access.

What is the primary difference between AMS and ASTM standards?

While both are material standards, AMS (Aerospace Material Specification) standards are specifically developed for the aerospace industry and often feature stricter requirements, tighter tolerances, and more comprehensive testing protocols. ASTM (American Society for Testing and Materials) standards are broader, covering a vast array of materials and industries, and may not always meet the higher criticality demands of aerospace applications.